Technical measures to ensure safety when working in electrical installations

When performing work in electrical installations, technical and organizational measures (measures) are taken to prevent accidental supply of voltage to the place of work and accidental approach or contact with live parts that remain live.

When performing work in electrical installations, technical and organizational measures (measures) are taken to prevent accidental supply of voltage to the place of work and accidental approach or contact with live parts that remain live.

Technical measures to ensure the safety of work in electrical installations are carried out in the following order:

1. Turn off the voltage and take measures to exclude its erroneous supply to the place of work,

2. Hang warning placards on switching equipment, on permanent and temporary fences,

3. Check that there is voltage on the part of the installation disconnected from operation and apply a portable ground to live parts of the installation.

Workplace preparation

In order to prepare the workplace for work, it is necessary to make the necessary interruptions and take measures to prevent the supply of voltage to the workplace due to spontaneous or erroneous switching on of switching equipment, to hang prohibition posters and, if necessary, to install fences, check for no voltage, apply portable earthing, hang warning and permit placards (this requirement is not necessary for full voltage relief works).

Live live parts are protected.

If the operational maintenance of the installation is carried out by two people per shift, the preparation of the workplace is carried out by two people. With one-person service — one person.

Disconnection

At the place of work, live parts on which work is carried out and those that can be touched during work must be switched off. It is allowed not to exclude adjacent parts, but to protect them with insulating pads.

To prevent the supply of voltage to the place of work due to transformation, it is necessary to disconnect from the high and low voltage sides all power, measuring and other transformers connected to the equipment being prepared for repair. This must be done in such a way that the sections of the electrical installation intended for operation are separated from live parts that are energized by switching devices or removed fuses.

Interruption can be done with manual switching devices whose contact position is visible from the front or back of the panel or.when opening the covers, as well as — through contactors and other remote-controlled switching devices with contacts accessible for inspection, after measures have been taken to exclude the possibility of false tripping, for example, auxiliary fuses have been removed.

Interruption can also be done by switching devices with closed contacts and manual control (circuit breakers, package switches, etc.) if there is complete confidence that the position of the handle or pointer corresponds to the position of the contacts. In this case, immediately after switching off, it is necessary to check the absence of voltage on all phases.

Hanging warning posters

Warning, prohibitory, prescriptive and directional posters are used to warn about the danger of approaching live parts, prohibit incorrect actions, indicate the place of work, etc.

"Do Not Switch On: People Are Working!" placards are posted on control switches and switch and switch actuators, as well as on fuse bases that can be used to apply voltage to the workplace.

When working on the line, poster «Do not turn on: work on the line!»

On temporary fences, posters "Stop. Voltage!». If there are no disconnected parts of the installation near the place of work, "Work here" placards are placed at all places prepared for the work.

It is prohibited to remove or rearrange the posters installed during the preparation of the workplace until the work is completed.

Workplace fence

Non-disconnected live parts accessible to accidental contact must be surrounded during operation with strong, well-reinforced insulating linings made of wood, getinax, textolite, rubber, etc. Placards or a warning sign “Stop . Voltage!».

Checking the absence of voltage

Before starting de-energization work, be sure to check that there is no voltage in the work area between all phases and between each phase and neutral conductors or ground.

This check is done with a pressure gauge or a portable voltmeter. The device must be designed for mains voltage. The use of pilot lamps in networks 380/220 V is prohibited.

Immediately before the test, you should make sure that the pointer or voltmeter is in good working order on nearby live parts that are known to be live. If there is no voltage source nearby, it is allowed to check the manometer or voltmeter in another place. If the device under test has been shaken and knocked or dropped, the test must be repeated.

Constantly on warning lights or voltmeters serve only as aids. Based on their testimony, it is impossible to draw conclusions about the absence of tension, but only about its presence. The deviation of the voltmeter or the burning of the warning lamp indicates the inadmissibility of operation of this equipment.

Applying and removing grounding

To protect workers from electric shock in the event of a wrong voltage supply, earthing is applied to all phases of the interrupted installation from all sides from where voltage can be applied (including by reverse transformation through welding transformers, local lighting transformers, etc. n. ). In case of operational maintenance, grounding can be done by one person.

For grounding, special portable grounding wires with connecting clamps are used. It is forbidden to use wires that are not intended for this purpose, as well as to connect the earth by twisting.

Grounding procedure

Before checking the absence of voltage, one end of the portable table is connected to a ground bus or grounded structure in a specially designed and unpainted area. Then the absence of voltage is checked. Immediately after checking the absence of voltage with the help of an insulating rod, portable grounding clamps are applied to the live parts that must be grounded and fixed with a stick or hands in dielectric gloves.

Removal of grounding is carried out in the reverse order: first disconnect the grounding from the live parts with a stick or hands in dielectric gloves, and then disconnect the clamp from the grounding device. If it is necessary to temporarily remove the grounding for carrying out work, for example, when testing insulation with a megohmmeter, then removal and reinstallation of the ground can be done by service personnel.

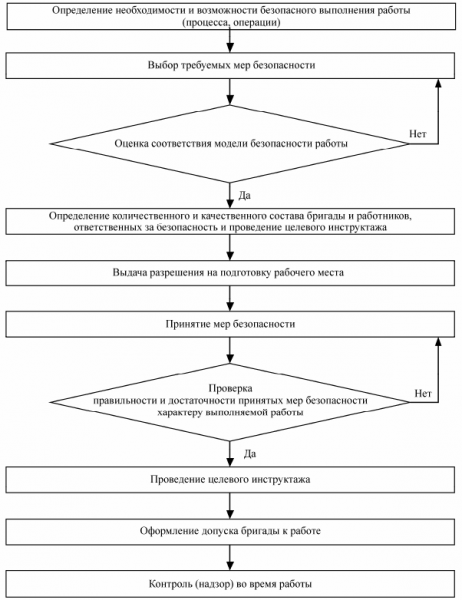

Reference Algorithm for Making a Decision to Perform Work in Electrical Installations

The reference decision-making algorithm for carrying out work in electrical installations, establishing the sequence of actions and activities that ensure the safe organization of work (author — Bukhtoyarov V.F.)