Copper and aluminum in electrical engineering

No guides — nowhere

Copper (lat. Cuprum) — one of the seven metals known from antiquity. Significant reserves of copper ore are found in the USA, Chile, Russia (Urals), Kazakhstan (Jezkazgan), Canada, Zambia and Zaire.

Copper is part of more than 150 minerals, 17 of them have found industrial use, including: bornite (Cu5FeS4), chalcopyrite (copper pyrite — CuFeS2), chalcocite (copper luster — Cu2S), covellite (CuS), malachite (Cu2 ( OH ) 2 [CO3]). The processing of sulphide ores provides about 80% of all mined copper.

Local honey is also found in nature.

Pure copper — malleable and soft pink brittle metal, quite heavy, excellent conductor of heat and electricity, easily subjected to pressure treatment. It is these qualities that make it possible to use copper products in electrical engineering — currently more than 70% of all copper produced is used for the production of electrical products. For products with maximum electrical conductivity, the so-called "oxygen-free" copper is used. In other cases, commercial pure copper containing 0.02-0.04% oxygen is also suitable.

The main characteristics of copper: specific gravity — 8.93 g / cm3, melting point — 1083 ° C,electrical resistance copper at 20 ° C 0.0167 Ohm * mm2 / m. Pure copper has a high electrical conductivity (second only to silver). This quality of copper is used in the industry to make electrical busbars from copper.

The main characteristics of copper: specific gravity — 8.93 g / cm3, melting point — 1083 ° C,electrical resistance copper at 20 ° C 0.0167 Ohm * mm2 / m. Pure copper has a high electrical conductivity (second only to silver). This quality of copper is used in the industry to make electrical busbars from copper.

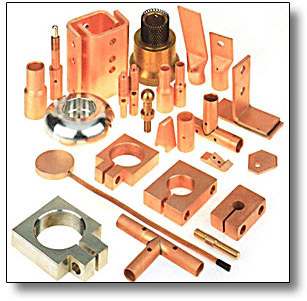

Copper busbars are produced in accordance with GOST 434-78. The state in which the copper busbars are delivered to the consumer: unheated (marking-T-hard), annealed (M-soft) and TV-hard busbars made of oxygen-free copper.

In the deformed state, the strength of copper is higher than that of annealed metal and the electrical conductivity values are reduced.

Alloys that increase the strength and improve other properties of copper are obtained by introducing additives into it, such as zinc, tin, silicon, lead, aluminum, manganese and nickel. More than 30% copper is used for alloys.

Brass - alloys of copper with zinc (copper from 60 to 90% and zinc from 40 to 10%) - stronger than copper and less susceptible to oxidation. With the addition of silicon and lead to brass, its anti-friction properties are increased, with the addition of tin, aluminum, manganese and nickel, the anti-corrosion resistance is increased. Sheets and cast products are used in machine-building, especially in the chemical industry, in optics and instrument-making, in the production of nets for the pulp and paper industry.

Bronze... Previously, alloys of copper (80-94%) and tin (20-6%) were called bronze. Lumenless bronzes are now produced, named after the main component after copper.

Aluminum bronzes contain 5-11% aluminum, have high mechanical properties combined with corrosion resistance.

Lead bronzes containing 25-33% lead are mainly used for the production of bearings operating at high pressure and high sliding speeds.

Silicon bronzes containing 4-5% silicon are used as cheap substitutes for tin bronzes.

Beryllium bronzes containing 1.8-2.3% beryllium are characterized by hardness after hardening and high elasticity. Springs and spring products are made from them.

Cadmium bronzes — copper alloys with a small amount of cadmium (up to 1%) — are used in the manufacture of carriages for trolleys, for the manufacture of fittings for water and gas pipes and in engineering.

Solders — alloys of non-ferrous metals used in soldering to obtain a monolithic welded seam. Among the hard solders, a copper-silver alloy (44.5-45.5% Ag; 29-31% Cu; the rest is zinc) is known.

In Russia, copper tires are produced by several factories: OCM Kamensk-Uralsky, OCM Kolchuginsky, OCM Kirovsky.

World production of copper in 2007 increased by 2.5% compared to 2006 and amounted to 17.76 million tons. Copper consumption increased by 4% in 2007, with China's copper consumption jumping 25% year-on-year, while US copper consumption fell sharply by 20%.

Aluminum and its alloys

Aluminum and a number of alloys based on it are used in electrical engineering due to good electrical conductivity, corrosion resistance, low specific gravity and, importantly, lower cost compared to copper and its conductive alloys.

Aluminum and a number of alloys based on it are used in electrical engineering due to good electrical conductivity, corrosion resistance, low specific gravity and, importantly, lower cost compared to copper and its conductive alloys.

Depending on the magnitude of the electrical resistance, aluminum alloys are divided into conductive and alloys with high electrical resistance.

The specific electrical conductivity of electrical aluminum grades A7E and A5E is about 60% of the conductivity of annealed copper according to the international standard. Technical aluminum AD0 and electrical aluminum A5E are used for the production of wires, cables and tires. Low-alloy aluminum alloys of the Al-Mg-Si AD31, AD31E systems are used in the electrical industry.

The earth's crust contains 8.8% aluminum. It is the third most abundant element in nature after oxygen and silicon and the first among metals. It is part of clays, feldspars, micas. Several hundred Al minerals are known (aluminosilicates, bauxites, alunites and others). The most important aluminum mineral — bauxite contains 28-60% aluminum oxide — aluminum oxide Al2O3.

In its pure form, aluminum was obtained for the first time by the Danish physicist H. Oersted in 1825, although it is the most common metal in nature.

The production of aluminum is carried out by electrolysis of aluminum oxide Al2O3 in cryolite melt NaAlF4 at a temperature of 950 ° C.

The main characteristics of aluminum: density — 2.7 × 103 kg / m3, specific heat of aluminum at 20 ° C — 0.21 cal / deg, melting point — 658.7 ° C, boiling point of aluminum — 2000 ° C, coefficient of linear expansion of aluminum (at a temperature of about 20 ° C): — 22.9 × 106 (1 / deg)

Aluminum alloys, which increase its strength and improve other properties, are obtained by introducing alloying additives such as copper, silicon, magnesium, zinc, manganese into it.

Duralumin (duralumin, duralumin, from the name of the German city where industrial production of the alloy began) - aluminum melt (base) with copper (Cu: 2.2-5.2%), magnesium (Mg: 0.2-2.7%) manganese ( Mn: 0.2-1%). Hardened and aged, often lined with aluminum. It is a structural material for aviation and transport engineering.

Silumin — light alloys of aluminum (base) with silicon (Si: 4-13%), sometimes up to 23% and some other elements: Cu, Mn, Mg, Zn, Ti, Be). Parts of complex configuration are produced by it, mainly in the automotive and aviation industries.

Magnalia — aluminum alloys (base) with magnesium (Mg: 1-13%) and other elements with high corrosion resistance, good weldability, high plasticity. They are used to make molded castings (cast magnalia), sheets, wire, rivets, etc. (Deformable Magnalia).

In terms of the scope of application, aluminum alloys take second place after steel and cast iron.

Some interesting facts about aluminum:

-

up to 140 mg of aluminum is present in the body of an adult,

-

1 kg of aluminum in a car saves more than 10 liters of gasoline every 200 thousand kilometers,

-

even apples contain aluminum — up to 150 mg / kg,

-

every 20th of the atoms that make up the upper shell of our planet is an aluminum atom,

-

the daily requirement of an adult for aluminum is estimated to be 2.45 mg.

With a lower specific conductivity (about 56% of annealed copper), aluminum conductor alloys serve the same purpose as electrical aluminum. Such alloys are used to meet high strength, creep and other special requirements.Aluminum tires are produced according to GOST 15176-89 from alloys AD31 and AD31T, less often AD0.

World consumption of primary aluminum in 2007 was 37.52 million tons, which was 3.184 million tons (or 9.3%) more than in 2006. World production of primary aluminum increased in 2007 by 4.024 million tons compared to 2006 and reached 38.02 million tons.

Manufacturers of copper products

The largest producer of copper on the Russian market — MMC Norilsk Nickel

The second largest honey producer in our country is the UMMC holding.

The third major player in the Russian market is the Russian Copper Company. CJSC "Russian Copper Company" includes 11 enterprises operating in four regions of Russia, as well as on the territory of Kazakhstan

There are copper tires on the market from several plants: Kamensk-Uralsky OCM, Kolchuginsky OCM, Artemovsky OCM, Kirovsky OCM. Kirovsky and Kolchuginsky OCM are part of OJSC UMMC.

Technologies and prices

Since the technology for the production of copper buses is known and is practically the same in all factories, the price / quality ratio comes to the fore for the consumer. Domestic enterprises - industry leaders currently produce quality products and compete with each other, mainly on price. But speaking about the quality of copper busbars, it is worth noting that impurities, even in very small quantities, significantly reduce the electrical conductivity of copper. Therefore, marriage has no place here.

At the same time, foreign and local enterprises offer innovative solutions that allow them to produce products with clearly defined quality parameters.Moreover, in particularly critical moments, the production of copper tires takes place according to our own, sometimes original solutions.

For example, OJSC «KUZOTSM» produces copper-silver alloy collector tapes. Such an alloy surpasses copper in operational characteristics and, unlike the alloy of copper with cadmium, is environmentally friendly. The plant also produces a number of critical electrical profiles. In particular, these are rectangular copper electrical profiles, such as semi-rigid tires, solid tires with increased surface coverage: tires with full rounding of the small sides of the section with different hardness, etc.

Semi-rigid tires are manufactured to meet British BS1432 surface quality requirements and to obtain semi-rigid mechanical properties. The tires are made from a pressed billet in two drawing passes with intermediate annealing, and finishing is done with a reduced degree of deformation compared to the traditional solid tire manufacturing scheme.

Tires with increased surface purity, intended for their subsequent electrolytic coating with silver, providing the highest electrical conductivity at the point of contact, and this dictates special requirements for their surface roughness (Rz≤0.63 microns according to GOST 2789-73). The roughness indicator required by the customer was achieved at KUZOTsM by a number of technological methods — the use of increased total reductions during drawing, additional preparation of the draw surface before drawing completion and the corresponding processing of a specially shaped channel from composite and monolithic dies. The above guaranteed level of roughness (Rz≤0.63 microns) allows the application of coatings of a given thickness uniformly on the surface of the tire.In this way, it is possible to create contact surfaces with low contact resistance and high electrical conductivity.

Tires with full rounding of the small sides of the section, that is, with a radius of curvature equal to half the thickness of the tire, have certain advantages over traditional ones: the wear resistance of the insulating coating increases due to the absence of bends in the corners of the profile, significant savings are achieved of copper, and the indicators of the distribution of the current load on the section are improved tires.

In a few months, relations between Russian manufacturers of electrical products and their foreign competitors should move to a new stage. This is due to the entry into the WTO. On the one hand, joining the WTO opens up a foreign market for Russian manufacturers. On the other hand, accession to the WTO means a mandatory reduction of import duties, which should be reduced by almost one and a half times in 3 4 years. The main competition will be in the quality of the products.

N. Alexandrov. Metals and prices