How flywheel (kinetic) energy storage devices are arranged and work

FES is short for flywheel energy storage, which means energy storage using a flywheel. This means that mechanical energy is accumulated and stored in kinetic form as a massive wheel rotates at high speed.

The mechanical energy thus accumulated can later be converted into electricity, for which the flywheel system is combined with a reversible electric machine capable of operating in both motor and generator modes.

When energy needs to be stored, the electric machine serves as a motor and rotates the flywheel to the required angular velocity while consuming electrical energy from an external source, in effect—converting electrical energy—into mechanical (kinetic) energy. When the stored energy needs to be transferred to the load, the electric machine goes into generator mode and mechanical energy is released as the flywheel decelerates.

The most advanced energy storage systems based on flywheels have a fairly high power density and can compete with traditional energy storage systems.

Kinetic battery installations based on super flywheels, where the rotating body is made of high-strength graphene ribbon, are considered particularly promising in this regard. Such storage devices can store up to 1200 W * h (4.4 MJ!) of energy per 1 KILOGRAM of mass.

Recent developments in the field of super flywheels have already allowed developers to abandon the idea of using monolithic drives in favor of less dangerous belt systems.

The fact is that monolithic systems were dangerous in case of emergency rupture and could accumulate less energy. When breaking, the tape does not scatter into large fragments, but only partially breaks; in this case, the separate parts of the belt stop the flywheel by rubbing against the inner surface of the housing and prevent its further destruction.

The high specific energy intensity of super flywheels made from winding tape or interference interference fiber is achieved due to a number of contributing factors.

First, the flywheel operates in a vacuum, which greatly reduces friction compared to air. For this, the vacuum in the housing must be constantly maintained by a vacuum creation and maintenance system.

Second, the system must be able to automatically balance the rotating body. Special technical measures are taken to reduce vibrations and gyroscopic vibrations. In short, flywheel systems are very demanding from a design point of view, therefore their development is a complex engineering process.

They seem to be more suitable as bearings magnetic (including superconducting) suspensions… However, engineers had to abandon low-temperature superconductors in suspensions, as they require a lot of energy. Hybrid rolling bearings with ceramic bodies are much better for medium rotational speeds. As for high speed flywheels, it has been found to be economically acceptable and very economical to use high temperature superconductors in suspensions.

One of the main advantages of FES storage systems, after their high specific energy intensity, is their relatively long service life, which can reach 25 years. By the way, the efficiency of flywheel systems based on graphene strips reaches 95%. In addition, it is worth noting the charging speed. This, of course, depends on the parameters of the electrical installation.

For example, an energy recuperator on a subway flywheel that operates during train acceleration and deceleration charges and discharges in 15 seconds. It is believed that in order to achieve high efficiency from the flywheel storage system, the nominal charge and discharge time should not exceed one hour.

The applicability of FES systems is quite wide. They can be successfully used on various lifting devices, providing energy savings of up to 90% during loading and unloading. These systems can be effectively used for rapid charging of electric transport batteries, for stabilizing frequency and power in electrical grids, in uninterruptible power sources, in hybrid vehicles, etc.

With all this, flywheel storage systems have remarkable features.So, if a high density material is used, then the specific power consumption of the storage device decreases due to a decrease in the nominal rotation speed.

If a low-density material is used, then the power consumption increases due to the increase in speed, but this increases the requirements for vacuum, as well as for supports and seals, and the electrical converter becomes more complex.

The best materials for super flywheels are high-strength steel belts and fibrous materials such as Kevlar and carbon fiber. The most promising material, as noted above, remains the graphene tape not only because of the acceptable parameters of strength and density, but mainly because of its safety in breaking.

The potential for breakage is a major obstacle for high-speed flywheel systems. Composite materials that are rolled and glued in layers quickly disintegrate, first delaminating into small-diameter filaments that instantly entangle and decelerate each other, and then into a glowing powder. Controlled rupture (in the event of an accident) without damage to the hull is one of the main tasks of engineers.

The release of rupture energy can be mitigated by an encapsulated fluid or gel-like inner casing lining that will absorb the energy if the flywheel breaks.

One way to protect against a blast is to put the flywheel underground to stop any debris that would fly at bullet speed in the event of an accident. However, there are cases when the flight of fragments occurs upwards from the ground, with the destruction of not only the hull, but also the adjacent buildings.

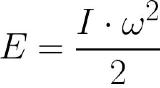

Finally, let's look at the physics of the process.The kinetic energy of a rotating body is determined by the formula:

where I is the moment of inertia of a rotating body

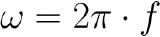

the angular velocity can be represented as follows:

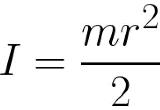

For example, for a continuous cylinder, the moment of inertia is:

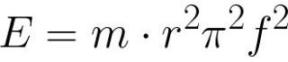

and then the kinetic energy for a solid cylinder through frequency f is equal to:

where f is the frequency (in revolutions per second), r is the radius in meters, m is the mass in kilograms.

Let's take a rough example to understand. A 3 kW boiler boils water in 200 seconds. At what speed must a continuous cylindrical flywheel of mass 10 kg and radius 0.5 m rotate so that during the process of stopping it there is enough energy to boil the water? Let the efficiency of our generator-converter (capable of operating at any speed) be 60%.

Answer. The total amount of energy required to boil the kettle is 200 * 3000 = 600,000 J. Taking efficiency into account, 600,000 / 0.6 = 1,000,000 J. Applying the above formula, we get a value of 201.3 revolutions per second .

See also:Kinetic energy storage devices for the power industry

Another modern way to store energy: Superconducting Magnetic Energy Storage Systems (SMES)