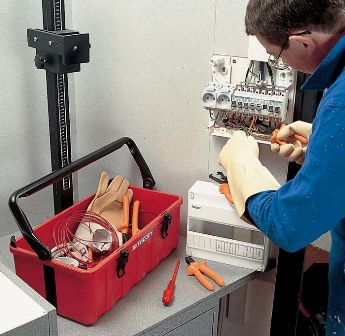

Tool with insulated handles

The tool with insulated handles is designed to work in electrical installations with a voltage of up to 1000 V without removing the voltage.

The handles of pliers, wire cutters, pliers, screwdrivers, wrenches are covered with moisture-resistant insulating materials. The material should not be fragile (so that it does not break if it accidentally falls on the floor). It must be resistant to corrosion from sweat, oil, gasoline, kerosene, acids. Therefore, ebonite, plastics and rubber are used to insulate tool handles.

The coating adheres tightly to the metal part of the hand grip tool.

For long tools (screwdrivers, wrenches), the cover covers a length greater than the length of the grip, leaving only the end with an open working part.

For tools with short handles (pliers), the insulation cover has a stop that limits the grip to the part where there is insulation. The length of the insulated tool handle must be at least 10 cm.

The surface of the insulating cover can be smooth or corrugated.

When working with tools with insulated handle handles. live parts without removing the voltage in electrical installations with a voltage of 220 — 380 V, dielectric gloves and galoshes must be used.

The need for this requirement is due to the fact that the possibility of touching live parts with a hand that does not have a tool with an insulated handle is not excluded. For example, you need to maintain the unscrewed part, nut, etc. with the other hand.

The glove can be worn on the non-tooled hand. Do not operate a tool with insulated handles where the working part of the tool could accidentally short live parts between them or to ground.