Villari effect, magnetoelastic effect — the reverse phenomenon of magnetostriction

Villari effect named after an Italian physicist Emilio Villariwho discovered this phenomenon in 1865. The phenomenon is also called magnetoelastic effect… Its physical essence lies in the change of magnetic permeability, as well as the associated magnetic properties of ferromagnets during mechanical deformation of samples made of these ferromagnets. The work is based on this principle magneto-elastic measuring transducers.

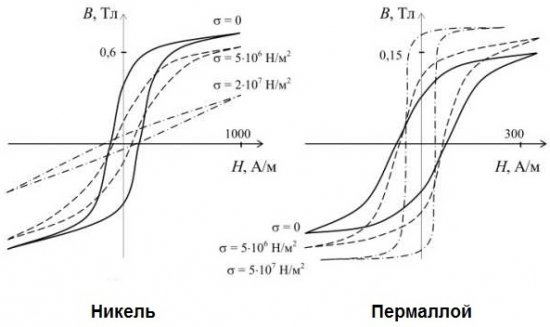

For example, look of hysteresis loops permaloid and nickel under operating conditions on mechanically stressed specimens made of these materials. So when a nickel sample is stretched, as the tensile stress increases, the hysteresis loop tilts. This means that the more nickel is stretched, the lower its magnetic permeability. The tensile strength of nickel also decreases. And permaloy is the opposite.

When the permalloy sample is stretched, the shape of its hysteresis loop approaches a rectangular one, which means that the magnetic permeability of the permalloy increases during stretching, and the residual inductance also increases. If the stress changes from tension to compression, then the sign of the change in magnetic parameters is also reversed.

The reason for the manifestation of the Villari effect of ferromagnets under deformation is as follows. When a mechanical stress acts on a ferromagnet, it changes its domain structure, that is, the domain boundaries shift, their magnetization vectors rotate. This is similar to magnetizing the core with a current. If these processes have the same direction, then the magnetic permeability increases, if the direction of the processes is opposite, it decreases.

The Villari effect is reversible, hence its name reverse magnetostrictive effect… The effect of direct magnetostriction consists in the deformation of a ferromagnet under the action of a magnetic field applied to it, which also leads to a displacement of the domain boundaries, to a rotation of the vectors of the magnetic moments, while the crystal lattice of the substance changes its energy state due to a change in the equilibrium distances of its nodes, due to displacement of the atoms from their original places. The crystal lattice is deformed so that for some samples (iron, nickel, cobalt, their alloys, etc.) the elongation reaches 0.01.

So, magnetostriction — the property of some ferromagnetic metals and alloys to deform (contract or expand) during magnetization and, conversely, to change magnetization during mechanical deformation.

This phenomenon is used to implement magnetostrictive resonators, where mechanical resonance occurs under the action of alternating magnetic fields. Magnetostrictive resonators can be manufactured for frequencies up to 100 kHz and even higher, and at these frequencies they find various applications for frequency stabilization (similar to piezoelectric quartz) for receiving ultrasound, etc.

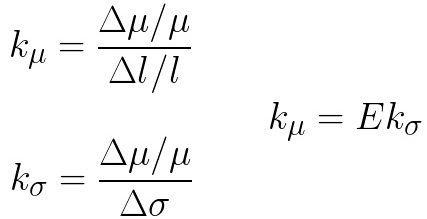

From the point of view of the magnetoelastic effect, the material can be characterized by such a parameter as coefficient of magnetoelastic susceptibility… It is defined as the ratio of the change in relative magnetic permeability of a substance to its relative strain or to the applied mechanical stress. And since relative change in length and mechanical stress are related Hooke's law, then the coefficients are related to each other by Young's modulus:

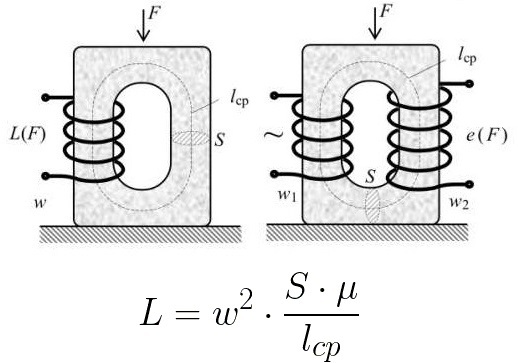

The change in the magnetic permeability of a material during its deformation can be converted into an electrical signal using inductive measurement (inductive or mutual inductive conversion).

It is known that the inductance of a coil on a closed magnetic circuit of constant cross-section is found by the following formula:

If now the magnetic circuit is deformed by the action of some external force, then the geometric dimensions and the magnetic permeability of the magnetic circuit (coil core) will change. Thus, the mechanical deformation changes the inductance of the coil. The change in inductance can be calculated using differentiation:

Ferromagnetic materials with a highly pronounced Villari effect allow to take:

For mutual inductive measurement conversion, the mutual inductance of the coils is changed:

The Villari effect is used in modern magneto-elastic measuring transducerswhich allow you to measure significant forces and pressures, mechanical stresses and deformations in various objects.