XLPE insulated cables: device, design, advantages, applications

Currently, there is a constant increase in the production and consumption of cables with XLPE insulation in the Russian market of cable and wire products. The Russian designation of these cables is XLPE, the English is XLPE, the German is VPE, and the Swedish is PEX.

Currently, there is a constant increase in the production and consumption of cables with XLPE insulation in the Russian market of cable and wire products. The Russian designation of these cables is XLPE, the English is XLPE, the German is VPE, and the Swedish is PEX.

Let's note the main advantages of cables with XLPE insulation (XLPE cables) over cables with impregnated paper insulation (BPI cables):

-

depending on the laying conditions, the throughput of XLPE cables is 1.2-1.3 times higher due to the higher permissible long-term temperature,

-

the thermal resistance of XLPE cables at short-circuit currents (SC) is higher due to the higher limiting temperature, the specific breakdowns of XLPE cables are 10-15 times lower than those of BPI cables,

-

long service life of XLPE-cable (provided by manufacturers for more than 50 years),

-

easier conditions for installation of XLPE cables due to lower weight, diameter, bending radius, absence of heavy lead (or aluminum) sheath,

-

XLPE cables can be laid at negative temperatures (up to -20 ° C) without preheating due to the use of polymer materials for insulation and sheath,

-

the absence of liquid components in the construction of XLPE cables reduces installation time and costs,

-

XLPE cables are extremely environmentally friendly due to the absence of oil leakage and environmental pollution in case of failure,

-

the hygroscopicity of the structural elements of the XLPE cable is much less than that of the BPI cable, high dielectric properties of the insulation,

-

XLPE cables have no restrictions on the level difference of the cable route.

Rice. 1. XLPE insulated cable

The main characteristic of XLPE cables is their fundamentally new insulation — cross-linked polyethylene... Polyethylene as an insulation has been known for a long time. But conventional thermoplastic polyethylene has serious drawbacks, the main of which is a sharp deterioration in performance at temperatures close to the melting point. Thermoplastic polyethylene insulation begins to lose its shape, electrical and mechanical characteristics already at a temperature of 85 ° C.

XLPE insulation retains its shape, electrical and mechanical characteristics even at 130 °C.

The term «cross-linking» or «vulcanization» refers to the treatment of polyethylene at the molecular level. The crosslinks formed in the process of crosslinking between polyethylene macromolecules create a three-dimensional structure that determines the high electrical and mechanical characteristics of the material, lower hygroscopicity and a wider operating temperature range.

In the global cable industry, two cross-linking technologies are used in the production of power cables, the main difference between which is the reagent with which the polyethylene cross-linking process takes place.

The most common technology is cross-linking with peroxide, when polyethylene is cross-linked with the help of special chemicals - peroxides in a neutral gas environment at a certain temperature and pressure. This technology makes it possible to obtain a sufficient degree of cross-linking throughout the thickness of the insulation and to guarantee the absence of air inclusions. In addition to good dielectric properties, it also has a wider operating temperature range than other cable insulation materials and excellent mechanical properties. Peroxide technology is used in the production of medium and high voltage cables.

Less common is zero strength crosslinking, where special compounds (silanes) are added to polyethylene to ensure crosslinking at a lower temperature. The application sector for this cheaper technology covers low and medium voltage cables.

The first Russian manufacturer of XLPE cables in 1996 was the Moscow company ABB Moskabel, which used peroxide cross-linking technology. In 2003, JSC "Kamkabel" became the first Russian manufacturer of XLPE cables made of silane cross-linked polyethylene.

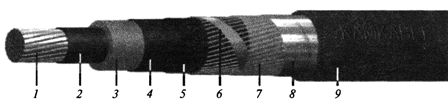

There are two versions of XLPE cables - three-core and single-core. XLPE cables are generally produced in a single-core design (Fig. 2).

Rice. 2.External view of a single-core XLPE cable: 1- round multi-wire sealed current-carrying conductor, 2- shield along the core made of semi-conducting cross-linked polyethylene, 3- insulation of cross-linked polyethylene, 4- shield along the insulation of semi-conducting cross-linked polyethylene, 5 — separation layer made of semiconducting tape or semiconducting waterproofing tape, 6 — shield of copper wires fastened with copper tape, 7 — separating layer of two ribbons of crepe paper, rubberized fabric, polymer tape or waterproofing tape, 8-separating layer of aluminum -polyethylene or mica tape, 9-wrap of polyethylene, PVC-plastic

A distinctive feature of the three-core version of the XLPE cable is the presence of an extruded phase-phase filler made of polyethylene or polyvinyl chloride (PVC) plastic mixture.

The use of single-core XLPE cables allows, first of all, to ensure increased reliability of the power supply due to a sharp reduction in the probability of a phase-phase short circuit. The probability of simultaneous destruction in one place of the insulation of two structurally unrelated single-core cables (connectors or end sleeves) corresponds to the probability of phase-phase damage of a bus with insulated busbars, i.e. very small.

The probability of single-phase earth faults with XLPE insulated single-core cables is much less than with three-core BPI cables. This is achieved both by the design of single-core XLPE cables and by the superior dielectric properties of the insulation.

The single-core version of XLPE cables allows a cross-section of current-carrying wires up to 800 mm. Cables with such a cross-section can successfully compete with the busbars used in the power supply systems of energy-intensive enterprises.

The shielding of the cable elements is necessary for the electromagnetic compatibility of the cable with various external circuits and to ensure the symmetry of the electric field around the core of the cable and therefore to create more favorable conditions for the operation of the insulation. The inner shields are made of semi-conductive plastic, the outer shield is made of copper wires and strips.

The outer protective sheath protects the internal elements of the cable from moisture penetration and mechanical damage during installation and operation. The outer sheaths of XLPE cables are made of high strength polyethylene or PVC compound.

Rice. 3. Cable with XLPE insulation APvPg

Conventional alphanumeric designations (marking) of cables with XLPE insulation:

-

A — aluminum conductor, no designation — copper conductor,

-

PV — insulating material — cross-linked (vulcanized) polyethylene,

-

P or V — casing made of polyethylene or PVC plastic,

-

y — reinforced polyethylene shell with increased thickness,

-

ng — sheath of PVC-compound with low flammability,

-

ngd — casing made of PVC compound with low smoke and gas emissions,

-

d — longitudinal sealing of the screen with waterproof tapes,

-

1 or 3 — the number of wires with current,

-

50—800 cross-section of the current-carrying wire, mm2,

-

gzh-sealing of the current-carrying wire, 2 16-35-cross-section of the screen, mm,

-

1-500 — nominal voltage, kV.

Designation example: APvPg 1×240 / 35-10-cable with aluminum core (A), XLPE insulation (Pv), polyethylene sheath (P), shielding (g), solid (1), conductor cross-section 240 mm. screen cross-section 35 mm, nominal voltage 10 kV.