Structures of insulated conductors of overhead power lines

The constructions of internally insulated wires are similar to wires of foreign manufacturers. The main constructions of household insulated wires are shown in fig. 1.

The constructions of internally insulated wires are similar to wires of foreign manufacturers. The main constructions of household insulated wires are shown in fig. 1.

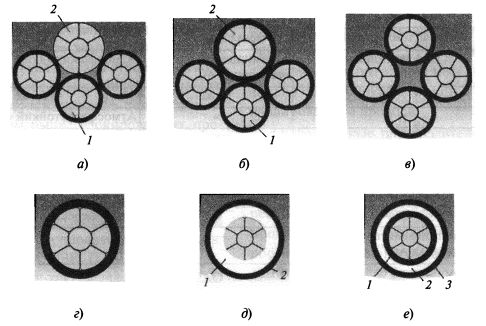

Insulated wires for voltage up to 1 kV (Fig. 1, a, b, c). For wires of types SIP-1 and SIP-2 (Finnish suspension system, analogues of AMKA and AHKA wires), the insulated phase conductors 1 are twisted around the non-insulated neutral conductor 2 in such a way that the entire mechanical load is perceived by the supporting neutral conductor .

For wires of types SIP-1A and SIP-2A (French suspension system, analogues of wires of types AMKat, AHKat, Torsada), the insulated phase conductors 1 are twisted around the insulated neutral conductor 2 in such a way that the entire mechanical load is perceived from the carrier wire 2.

For SIP-4 conductors (Swedish suspension system, analogues of EX and ALUS conductors), the insulated phase conductors and the insulated neutral conductor are twisted in such a way that the entire mechanical load is distributed evenly among the four conductors.

Rice. 1. Designs of insulated wires: a SIP-1, SIP-2 (Finnish system), b SIP-1A, SIP-2A (French system), c SIP-4 (Swedish system), g SIP-3, e PZV, e PZVG

All types of SIP wires have a round, stranded, sealed, aluminum conductor with current. The carrier neutral conductor (SIP-1, SIP-1 A, SIP-2, SIP-2A) is made of thermally strengthened aluminum alloy ABE, which provides the necessary electrical and mechanical characteristics. An aluminum construction of a support wire with a galvanized steel core (similar to an AC wire) is allowed.

The neutral wire SIP-4 has a design that is completely similar to that of the phase wires.

The insulation of the SIP-1, SIP-1 A and SIP-4 wires is made of thermoplastic weather-resistant (light-stabilized) black polyethylene, the insulation of the SIP-2 and SIP-2A wires is made of weather-resistant black cross-linked polyethylene .

The domestic industry (JSC "Sevkabel") produces modifications of SIP-4 wires: SIPs-4 with insulation from XLPE, SIPn-4 with insulation from a fire-resistant polymer composition.

If necessary, other conductors can be added to all self-supporting insulated conductors, for example, street lighting conductor. For easier installation and operation, insulated cores of self-supporting insulated wires have a distinctive designation in the form of longitudinal marks on the surface of the insulation.

All the above-mentioned internal self-supporting insulated conductors with a voltage of up to 1 kV in terms of design, technical characteristics and operational properties comply with the HD 626 S1 standard of the European Committee for Electrotechnical Standardization (CENELEC).

Insulated wires for voltages above 1 kV (Fig. 1, d, e, f). SIP-3 insulated wires (similar to the Finnish SAX wire) are single-core and are intended for overhead power lines up to 20 kV. In terms of design, technical characteristics and operational properties, the wires comply with the Finnish standard SFS 5791, 1994.

Wire SIP-3 is an insulated multi-wire sealed conductive wire made of aluminum alloy, which provides the necessary electrical and mechanical characteristics. It is permitted to perform a current-carrying wire made of aluminum with a galvanized steel core. The protective insulating cover is made of weather-resistant black XLPE.

Until recently, the domestic industry did not produce insulated wires for overhead power lines with a voltage of 35 kV. For the first time in Russia, employees of JSC "Sevkabel" developed TU 16.K10-0172003 "Wires with protective insulation for overhead power lines with a voltage of 35 kV" for two brands of wires: PZV and PZVG (protected moisture-resistant and sealed wires).

Single-core conductors PZV and PZVG. The core consists of sealed aluminum alloy conductors to provide the required electrical and mechanical properties. It is permitted to perform a current-carrying wire made of aluminum with a galvanized steel core. To prevent the migration of moisture along the channels between the wires when the core is twisted, water-blocking threads are introduced.Upon contact with water, the adsorbent contained in these threads absorbs water, increases many times in volume, fills all the voids between the wires and excludes the further spread of moisture along the wire.

The PZV conductor insulation consists of two layers: bottom layer 1 is XLPE, top layer 2 is weatherproof XLPE.

The insulation of the PZVG conductor (lightning resistant) consists of three layers: the first layer 1 of electrically conductive XLPE, the second layer 2 of pure insulating XLPE, the third layer 3 of tracking-resistant weatherproof XLPE (Fig. 1, f ).

The almost 10-year experience of operating VLI and VLZ with imported and internally insulated wires in Russia shows the undeniable advantages of such wires over bare wires, especially in terms of power supply reliability. But only recently has it become possible to build VLI and VLZ using high-quality internally insulated wires and fittings to them, which significantly reduces investment in new construction.