Heat resistance and fire resistance of cables and wires, non-combustible insulation

It is impossible to imagine the modern world without wired and cable communications, the volume of which, by the way, is constantly growing and growing. The high density of electrical cables in various, not always ideal conditions for cable insulation, increases the risk of fires. For example, every year in the US due to fires caused by cable fires, the state economy suffers losses of about 6 billion dollars. So the question of creating reliable fire-resistant cables and wires that do not spread combustion is becoming more and more urgent.

So, the fire safety of the cable is determined by the following five indicators:

Non-propagating combustion

The non-propagation of combustion is understood as the ability of the cable to self-extinguish immediately after the flame has ceased. This indicator can be quantified along the length of the cable damaged by fire after the end of the flame.

Smoke optical density

The maximum specific optical density of the medium in the space during the burning of an experimental cable sample characterizes the level of smoke characteristic of this type of cables during their burning. This parameter reflects how quickly smoke spreads in a room affected by a fire if such a cable is turned on. This is important to determine the conditions for extinguishing a fire.

Corrosion activity of outgassing products

The higher the corrosiveness of the outgassing products, the greater the fire damage. With high corrosiveness of gas release products, electrical equipment in a room covered by fire is destroyed. Quantitatively, this parameter is determined by the release of: hydrogen chloride, hydrogen bromide, sulfur dioxide, etc. — from the quantity of such active products.

Gas toxicity

As a rule, the toxicity of gas emissions leads to accidents and casualties in fires. These toxic products are mainly: ammonia, carbon monoxide, hydrogen cyanide, hydrogen sulfide, sulfur dioxide, etc.

Fire resistance

Fire-resistant cables retain their characteristics under the influence of an open flame, this indicator is calculated over time — from 15 minutes to 3 hours — during which time the fire-resistant cable can continue to work.

Cable insulation and fire resistance

The fire safety of the cable is mainly determined by the material of its insulation and protective coating, as well as by the design of the cable. The polymer materials used for the production of insulation are characterized by such fire safety parameters as:

-

Flammability;

-

Oxygen index;

-

Smoke production coefficient;

-

Corrosion activity of outgassing products;

-

Toxicity of combustion products.

Flammability

According to GOST 12.1.044-89, the flammability of materials is characterized, that is, their ability to burn. Materials differ: non-combustible, difficult to burn and combustible.

Non-combustible materials are generally unable to burn in air. Non-combustible materials can ignite in the presence of air, but once the source of flame is removed, they cannot continue to burn on their own.

Flammable materials are capable of self-ignition and can continue to burn after the source of the flame is removed. The important thing here is that quantitative indicators of flammability often do not fully indicate the fire safety of the cable.

Oxygen index

For a more accurate assessment of the flammability of the material during the test, the "oxygen index" is used, which is equal to the minimum volume of oxygen in the nitrogen-oxygen mixture, at which a stable burning of the given material can take place. An oxygen index of less than 21 indicates the flammability of the material, that is, such material can burn in air even after the ignition source has been removed.

Smoke production coefficient

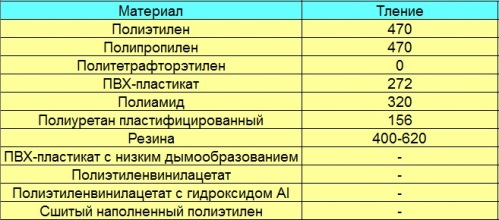

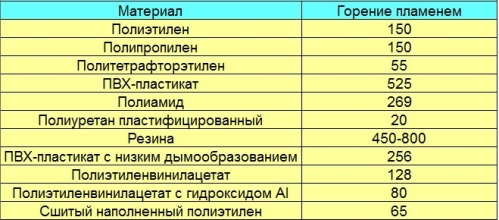

As noted above, the smoke coefficient reflects the optical density of the smoke during combustion of the material in the test chamber or indoors. This parameter is determined by photometrically recording the attenuation of illumination due to the passage of light through a space filled with smoke. The US National Bureau of Standards, for example, defines two smoke ratios: smoldering and flaming. The maximum smoke optical density is determined for different materials:

Corrosion activity of outgassing products

According to the content of hydrogen chloride, hydrogen bromide, sulfur oxide and hydrogen fluoride, according to IEC recommendations, the corrosiveness of the outgassing products is evaluated. For this, known analytical methods are used, when the sample is heated in a combustion chamber to a temperature of 800 ° C for 20 minutes.

Toxicity of combustion products

Through the amount of toxic gases released during combustion, such as: carbon monoxide, carbon dioxide, hydrogen chloride, hydrogen fluoride, hydrogen bromide, sulfur oxide, nitrogen oxide and hydrogen cyanide, the degree of toxicity of the combustion products is evaluated when testing the material heated to a temperature 800 ° C. Well-known fact: mainly in the cable industry, PVC insulations, rubber and polyethylene are used for insulation.

PVC compound is the least flammable material due to its chemical structure, in which there are no double bonds in the molecules and there are chlorine atoms.

In the event of a fire, PVC decomposes and releases hydrogen chloride, which prevents the fire from spreading. But when interacting with water or steam, hydrogen chloride turns into hydrochloric acid, which is very corrosive. In addition, hydrogen chloride is dangerous to humans, so the use of PVC is limited in the production of insulation for fireproof and fireproof cables.

Increased fire resistance and heat resistance

By adding inhibitors to PVC it is possible to increase its fire resistance. So, the introduction of phosphate plasticizers, flame retardants, fillers — reduces the flammability of PVC compounds. At the same time, gas emissions in the event of a fire are also reduced, as the inhibitors bind hydrogen chloride, precipitating it in the form of a non-flammable room.

Polyethylene is more flammable, and in order to make polyethylene insulation non-combustible, flame retardants are added to it, which contribute to the self-extinguishing of polyethylene insulation based on the modified composition. The most common solution is a mixture of antimony trioxide and chlorinated paraffin, due to which an advantage over PVC is achieved - reduced gas emission, reduced toxicity and danger to people.

As for rubber insulation, rubber is the least flammable. polychloroprene rubber, which became widely used as a cable sheath material. The most fire-resistant rubber is silicone rubber, chlorosulfonated or chlorinated polyethylene ("hypalon") and other rubber-like polymers.

Polymers based on fluoropolymers such as tetrafluoroethylene are highly flame-resistant due to their very high oxygen index and low evaporation. But at cable sheath temperatures above 300°C, such materials become toxic, dangerous to humans, and also corrosive to electrical equipment.

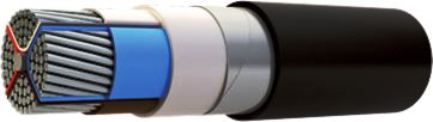

Impregnated paper-insulated and aluminum-sheathed cables were the first fire-resistant power cables.

High-voltage cables of the TsAABnlG and AABnlG brands in bundles do not spread combustion and withstand 20 minutes of exposure to an open flame on the sheath, that is, the fire resistance of these cables has been confirmed in tests.

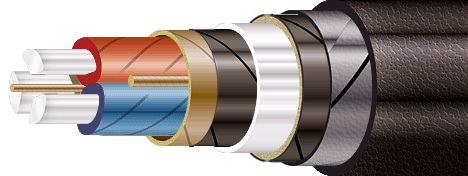

Their protective cover has a complex structure: a pair of galvanized steel strips and a fiberglass cushion under the bumper. In addition, fire resistance is provided by the presence of shells, armor and metal screens, which help to improve the quality and fire resistance of cables, even with plastic insulation.

When flame retardancy is required from the cable, then armored cable with PVC insulation of copper or aluminum conductors of sector or round shape is used. On the cores twisted together with the filling, a coil of polyethylene terephthalate or polypropylene strips is added, which are arranged with a gap.

After applying the strips, a self-extinguishing polyethylene belt insulation is made by extrusion. Next, a strip of semiconducting cable paper with a gap is applied, then a pair of 0.3 to 0.5 mm thick steel strips forming an armor. The upper belts cover the gaps of the underlying belts. The body is made of a low-flammability PVC mixture with a thickness of 2.2-2.4 mm.

As a result, the sheath combined with tapes fully meets the flame retardant requirements for AVBVng and VBVng cables when laid in bundles, despite the plain PVC covering.

Some useful solutions for refractory cables are strips of glass mica over the core. Such fire-resistant barriers, together with a PVC compound, ensure long-term resistance of the cable sheath to the action of the flame; they are used in cables for voltages up to 6 kV.

Formulations that do not emit hydrogen halides when burned, such as cross-linked polyethylene with flame retardants and mineral fillers, are best for fire protection of cables.

In addition, sometimes water-based emulsion paints and inks with non-combustible components are applied to the cable sheath, by spraying or brushing, to provide additional protection to the cable. The layer is applied with a thickness of approximately 1.5 mm, while the current carrying capacity of the cable is reduced by only 5%.

Heat-resistant cables with mineral insulation and in steel sheaths, such as KNMSpZS, KNMSpN, KNMSS, KNMS2S, etc., are widely used. Here, the wires are enclosed in sheaths of alloy or stainless steel. The insulation between the cores and the shells is made of magnesium oxide or periclase.