Conductor of the future (hollow cable) or saving resources in cable production

The production of cable lines and busbars is directly related to the extraction and production of: aluminum and copper, as these are the main conductors. Today, it is worth thinking that these resources are exhaustible and non-renewable, and due to the fact that humanity is gradually developing, more and more of these resources are needed. Therefore, our future requires the development of new materials and the more economical (rational) use of resources. This paper will propose a new approach to the production of cable lines based on the surface effect in the conductor — the skin effect.

ENHANCEMENT OF NATURAL RESOURCES — Today, with the pace of human development, the need for natural resources is increasing, and they are, in turn, divided into renewable and non-renewable.

All resources are not free, limited and rare. The concept of limited resources is quite common. Only in conditions of scarcity and limited resources, on the basis of which goods are created, problems of an economic nature arise.Economic problems do not arise if the volume of goods and resources with which human needs are satisfied are unlimited. But their rational use can increase the competitiveness of a producer interested in the efficient use of resources and maximization of profits, as well as satisfy some of the human needs.

The objective foundations of the competitiveness of manufacturers in the market are determined by their ability to compete with other manufacturers operating in the same market segment and producing similar products, as well as to achieve and maintain a strong competitive position for a long period of time. This is the main condition for its successful operation, ultimately expressed in terms of profitability.

To do this, on the one hand, you need to know the main characteristics of the competitive position that it wants to occupy in the future, and on the other hand, to have a clear idea of what resources and capabilities give a competitive advantage, which it must have for this and which of them is actually available or will be available. [1]

The main materials in the production of cables and busbars are copper and aluminum - this is due to their high electrical conductivity, sufficiently high mechanical strength, corrosion resistance, good workability, the possibility of easy soldering and welding.

Since this resource is exhaustible, a more economical and efficient use is required.

Speaking about the economical and efficient development of the direction of electricity transmission along cable lines and bus channels, the following directions can be considered:

1) Development of new materials corresponding to the necessary electrical characteristics for the transmission of electrical energy.

2) Development of methods for the production of cable lines and busbars.

3) Development of new methods of transmission of electrical energy.

In this paper, a new method in cable production will be proposed, which is based on the method of surface spreading effect — skin effect.

Surface effect in the conductor. Skin effect. Frequency properties

Alternating current is accompanied by electromagnetic phenomena that lead to the displacement of electric charges from the center of the conductor to its periphery. This effect is called the surface effect or skin effect. As a result of this effect, the current becomes inhomogeneous. In the periphery, the current turns out to be greater in magnitude than in the center. This is due to the difference in the density of free charge carriers in the perpendicular cross-section of the conductor with respect to the direction of the current.

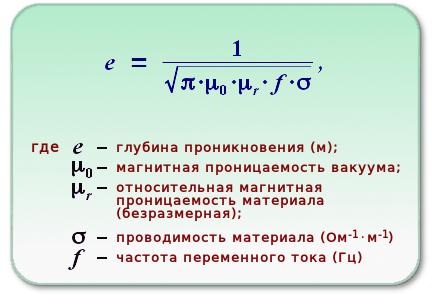

The current penetration depth is determined according to the expression:

Using the above formula for copper wire, at a current frequency of 50 Hz, the penetration depth is approximately 9.2 mm. In effect, this means that having a circular cross-section wire with a radius greater than 9.2 mm, there will be no current in the center of the wire because there will be no free charge carriers.

The higher the current frequency, the smaller the penetration depth. A two-fold increase in current frequency will result in a reduction in penetration depth to the square root of two. If the frequency of the current increases by 10 times, then the penetration depth will decrease by the root of 10 times.

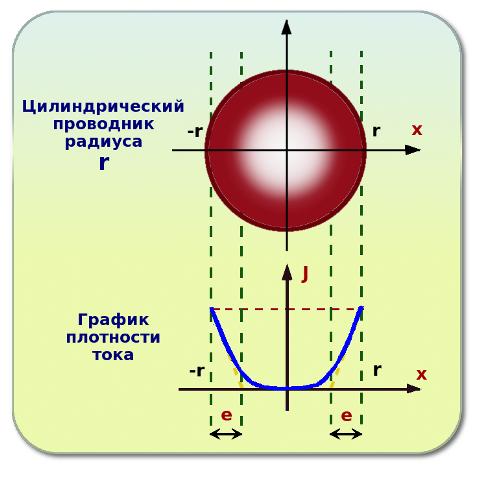

Current distribution graph

The graph clearly shows the distribution of current density J in a round conductor (cylindrical).Beyond the penetration depth, the current density is zero or negligible because there are no free electrons at these locations on the wire. There is no current in these places.

If conductive material is removed from the center of such a wire, where there is no current, then we get a hollow wire in the form of a tube (tube). Conductive characteristics will not change from this, since there was no current there, the resistance of such a wire will not change, but such characteristics as inductance and capacitance of the wire can change.

Practical use of the skin effect

Considering the current penetration depth for different frequencies, if a wire with a radius greater than the penetration depth is required, then it is reasonable to use a multi-core cable. Let's say that for a current frequency of 50 Hz, the limiting radius is about 9 mm, which means that it does not make sense to work with a solid wire with a radius of more than 9 mm. This will not give any increase in conductivity because there will be no current in the center of the wire, which is an irrational use of expensive copper. That is why multi-core wires and cables are used for large cross-sections. [2]

In order to save resources, it is assumed that a hollow wire with a wire thickness of more than 9 mm is used.

Today, Luvata manufactures hollow wires.

Luvata offers a wide range of copper hollow wires for generators, magnet coils, induction furnaces and a wide variety of other applications.

The size range of the hollow wire is from 4 x 4 mm (20 kg / m).

The hollow wires are made of high purity OF-OK® oxygen-free copper with high electrical conductivity, not less than 100% IACS.If it is necessary for the technical properties of the hollow wire to have a higher softening point or a higher creep index of the metal containing silver copper, brands CuAg 0.03% or CuAg 0.1%, produced on the basis of copper OF- OK®, were used.

Hollow copper wires are widely used in industries such as power generation, medical and research equipment. [3]

Hollow wire applications

-

Magnetic resonance machines

-

Magnets for high energy physics applications

-

Particle accelerators

-

Generators

-

Induction ovens

-

Plasma research equipment

-

Electrodynamic shakers

-

Ion alloy installations for the production of microcircuits

-

High Intensity Magnetic Field Separators

But today there is no production of hollow wire cable lines.

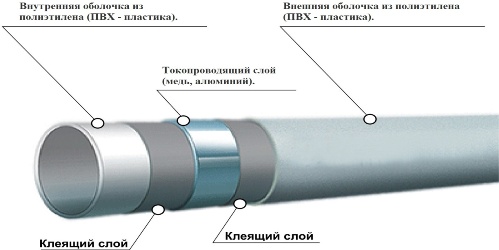

We suggest using the following cable line design.

Figure 1. Hollow wire

We also suggest using a stranded sheath.

Figure 2. A stranded hollow wire with a cavity filled with PVC

This development allows for economical and rational use of resources.