Insulation quality indicators — resistance, absorption coefficient, polarization index and others

Dielectric insulation is a mandatory insulating part of any cable, which not only separates the conducting wires from each other, physically isolates them, but also protects the wires from the harmful effects of various environmental factors. A cable can have one or more such sheaths.

The condition of these projectiles is one of the defining criteria in terms of safety for both personnel and equipment operability. If for some reason the dielectric insulation of the wires breaks, it will cause an accident, electric shock to people or even a fire. And there are many possible reasons for a violation of the quality of insulation:

-

mechanical damage during installation, repair or excavation work;

-

insulation damage from moisture or temperature;

-

unscrupulous electrical connection of wires;

-

systematic exceeding of the permissible current parameters for the cable;

-

finally the natural aging of insulation...

It is important to regularly monitor the indicators of the quality of the insulation.

Anyway, the complete replacement of the wiring is always very materially expensive and takes a long time to act, not to mention the losses and losses incurred by the enterprise from power outages and from unplanned downtime of the equipment. As for hospitals and some strategically important facilities, for them, disruption of the regular power supply regime is generally unacceptable.

That is why it is much more important to prevent the problem, to prevent deterioration of the insulation, to check its quality in time, and when necessary — to promptly repair, replace and avoid accidents and their consequences. For this purpose, measurements of insulation quality indicators are carried out — four parameters, each of which will be described below.

Although the insulating substance actually is dielectric, and should not conduct electric current, like an ideal flat capacitor, however, in a small amount, there are free charges in it. And even a small displacement of the dipoles also causes poor electrical conductivity (leakage current) of the insulation.

In addition, due to the presence of moisture or dirt, surface electrical conductivity also appears in the insulation. And the accumulation of energy in the thickness of the dielectric from the action of direct current is completely isolated as a kind of small capacitor, which seems to be charged through some resistor.

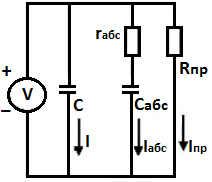

In principle, the insulation of a cable (or the winding of an electric machine) can be represented as a circuit consisting of three circuits connected in parallel: the capacitance C, which represents the geometric capacitance and causes the polarization of the insulation throughout the volume, the capacitance of the wires and the entire volume of a dielectric with a series-connected absorption resistance, as if the capacitor were charged through a resistor. Finally, there is a leakage resistance throughout the volume of the insulation, which causes a leakage current through the dielectric.

Parameters characterizing the quality of electrical insulation

In order to ensure that electrical insulation does not cause violations of the operating modes of electrical equipment and the safety of its operation, it is necessary to ensure its high quality, determined by the degree of electrical conductivity (the lower the electrical conductivity, the higher is the quality ).

When the insulation is switched on under voltage, electric currents pass through it due to the inhomogeneity of the structure and the presence of conductive inclusions, the magnitude of which is determined by the active and capacitive resistance of the insulation. The capacity of the insulation depends on its geometric dimensions. Within a short period of time after switching on, this capacity is charged, accompanied by the passage of an electric current.

Broadly speaking, three types of current flow through insulation: polarization, absorption, and continuous current. The polarization currents caused by the displacement of the associated charges in the insulation until the equilibrium state is established (fast polarization) are so short-lived that they are usually undetectable.

This leads to the fact that the passage of such currents is not associated with energy losses, therefore, in the equivalent circuit of the insulation resistance, the branch that takes into account the passage of polarization currents is represented by pure capacity, without active resistance.

The sink current due to delayed polarization processes is related to energy losses in the dielectric (for example, to overcome the resistance of the molecules when the dipoles are facing the direction of the field); therefore, the corresponding branch of the equivalent resistance also includes an active resistance.

Finally, the presence of conductive inclusions in the insulation (in the form of gas bubbles, moisture, etc.) leads to the appearance of through channels.

The electrical conductivity (resistance) of insulation is different when it is exposed to direct and alternating voltage, because with alternating voltage, absorption currents pass through the insulation during the entire time of exposure to voltage.

When exposed to constant voltage, the quality of the insulation is characterized by two parameters: active resistance and capacity, indirectly characterized by the ratio R60 / R15.

When an alternating voltage is applied to the insulation, it is impossible to separate the leakage current into its components (through conduction current and absorption current), therefore the quality of the insulation is judged by the amount of energy loss in it (dielectric losses).

The quantitative characteristic of losses is dielectric loss tangent, that is, the tangent of the angle complementary to the angle between the current and the voltage in the insulation up to 90 °.In the case of ideal insulation, it can be represented as a capacitor in which the current vector is ahead of the voltage vector by 90 °. The more power dissipated in the insulation, the higher the dielectric loss tangent and the worse the quality of the insulation.

In order to maintain the level of electrical insulation that meets the safety requirements and the mode of operation of electrical installations, PUE provides for regulation of the insulation resistance of networks. Periodic insulation tests are standardized for consumers of electrical energy.

The insulation resistance between each conductor and earth, as well as between all conductors in the area between two adjacent fuses in a distribution network with a voltage of up to 1000 V, must be at least 0.5 MΩ. For measuring and testing the insulation resistance in electrical installations up to 1000 V most often megometers are used.

Insulation resistance Riso

The measurement principle is as follows. When a constant voltage is applied to the plates of the capacitor, a charge current pulse first appears, the value of which at the first moment of time depends only on the resistance of the circuit, and only then is the absorption capacity (polarization capacity) charged, while the current decreases exponentially and here you can experimentally find time constant RC. Thus, with the help of an insulation parameters meter, the insulation resistance Riso is measured.

The measurements are carried out at a temperature not lower than + 5 ° C, because at a lower temperature the influence of cooling and freezing moisture is reflected and the picture becomes far from objectivity.After removal of the test voltage, the charge on the "isolation capacitor" begins to decrease as dielectric absorption of charge occurs.

DAR absorption rate

The degree of current moisture content in the insulation is reflected numerically in the absorption coefficient, because the more the insulation is wetted, the more intense is the dielectric absorption of the charge inside it. Based on the value of the absorption coefficient, a decision is made about the need to dry the insulation of transformers, motors, etc.

Calculate the ratio of the insulation resistances after 60 seconds and 15 seconds after the resistance measurements begin—this is the absorption coefficient.

The more moisture in the insulation, the greater the leakage current, the lower the DAR (dielectric absorption coefficient = R60 / R15). In wet insulation, there are more impurities (the impurities are in moisture), the resistance due to impurities decreases, the losses increase, the thermal breakdown voltage decreases, and the thermal aging of the insulation is accelerated. If the absorption coefficient is less than 1.3, it is necessary to dry the insulation.

Polarization index PI

The next important indicator of the quality of insulation is the polarization index. It reflects the mobility of charged particles inside a dielectric under the influence of an electric field. The newer, more intact and better the insulation, the less charged particles move inside it, as in a dielectric. The higher the polarization index, the older the insulation.

To find this parameter, the ratio of the insulation resistance values after 10 minutes and 1 minute after the start of the tests is calculated. This coefficient (polarization index = R600 / R60) practically shows the residual resource of the insulation as a high-quality dielectric that can still perform its function. The polarization index PI must not be less than 2.

Dielectric discharge coefficient DD

Finally, there is the coefficient of dielectric discharge. This parameter helps to identify a defective, damaged layer among layers of multilayer insulation. DD (Dielectric Discharge) is measured as follows.

First, the insulation is charged to measure its capacity, after termination of the charging process a leakage current remains through the dielectric. Now the insulation is short-circuited and one minute after the short-circuit the residual dielectric discharge current is measured in nanoamperes. This current in nanoamps is divided by the voltage to be measured and the insulation capacitance. DD must be less than 2.