How transoceanic submarine communication cables work

Our entire planet is tightly wrapped in wired and wireless networks for various purposes. A very large proportion of this entire information network consists of data cables. And today they are laid not only by air or underground, but even under water. The concept of a submarine cable is not new.

The beginning of the implementation of the first such ambitious idea dates back to August 5, 1858, when the countries of two continents, the United States and Great Britain, were finally connected by a transatlantic telegraph cable, which remained in good condition for a month, but soon began to collapse and finally broke due to corrosion. Communication along the route was reliably restored only in 1866.

Four years later a cable from the United Kingdom was laid to India, connecting Bombay and London directly. The best industrialists and scientists of that time participated in the development of the projects: Wheatstone, Thomson, the Siemens brothers. Although these events took place a century and a half ago, even then people were creating communication lines thousands of kilometers long.

The work of engineering thought in this and other areas also developed in 1956.a telephone connection with America is also established. The line can be called "voice from across the ocean", like the book of the same name by Arthur Clarke, which tells the story of the construction of this transoceanic telephone line.

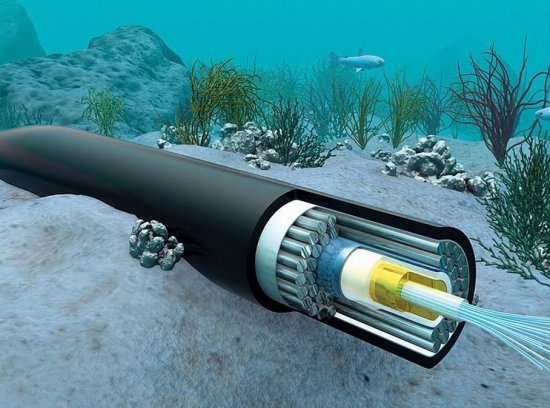

Surely many are interested in how the cable is designed, designed to work at a depth of up to 8 kilometers under water. Obviously, this cable must be durable and absolutely waterproof, strong enough to withstand enormous water pressure, not to be damaged both during installation and during future use for many years.

Accordingly, the cable must be made of special materials that would allow maintaining acceptable operational characteristics of the communication line even under mechanical tensile loads, and not only during installation.

Consider, for example, Google's 9,000-kilometer Pacific fiber optic cable that connected Oregon and Japan in 2015 to provide a data transfer capability of 60 TB/s. The cost of the project was 300 million dollars.

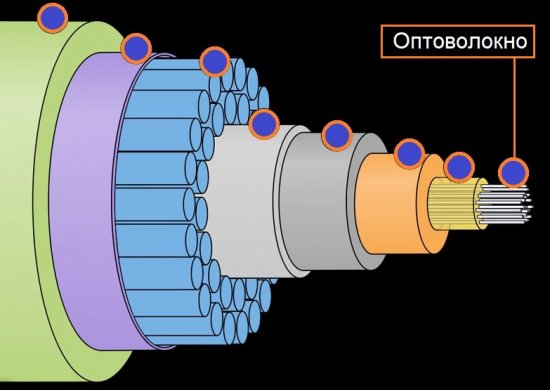

The transmitting part of the optical cable is not unusual in anything. The main feature is the protection of the deep sea cable to protect the optical core transmitting information during its intended use at such a great depth, while increasing the service life of the communication line. Let's look at all the components of the cable in turn.

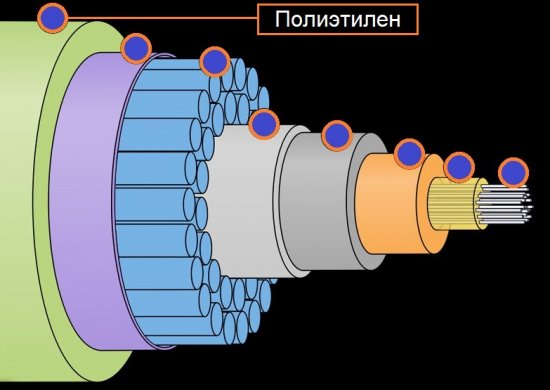

The outer layer of cable insulation is traditionally made of polyethylene. The choice of this material as an external coating is not accidental.Polyethylene is resistant to moisture, does not react with alkalis and salt solutions present in ocean water, and polyethylene does not react with either organic or inorganic acids, including even concentrated sulfuric acid.

And although the waters of the world ocean contain all the chemical elements of the periodic table, it is polyethylene that is the most justified and logical choice here, because reactions with water of any composition are excluded, which means that the cable will not suffer from the environment.

Polyethylene was used as insulation and in the first intercontinental telephone lines built in the mid-20th century. But since polyethylene alone, due to its natural porosity, is not able to fully protect the cable, additional protective layers are also used.

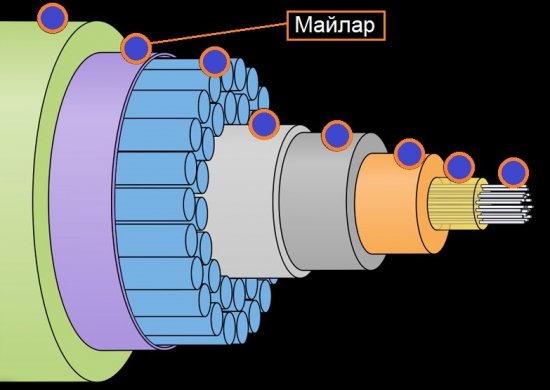

Underneath the polyethylene is a mylar film, which is a synthetic material based on polyethylene terephthalate. Polyethylene terephthalate is chemically inert, resistant to very aggressive environments, its strength is ten times higher than polyethylene, resistant to impact and wear. Mylar has found wide application in industry, including space, not to mention numerous applications in packaging, textiles, etc.

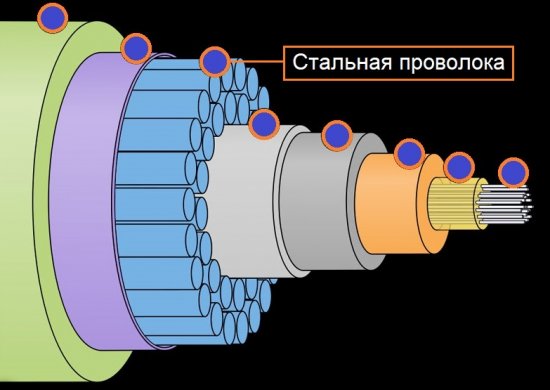

Under the mylar film there is an armature, the parameters of which depend on the characteristics and purpose of a particular cable. It is usually a solid steel braid that gives the cable strength and resistance to external mechanical loads. Electromagnetic radiation from the cable can attract sharks, which can bite the cable, and simply getting caught by fishing tackle can become a threat if there are no fittings.

The presence of galvanized steel reinforcement allows you to safely leave the cable at the bottom without the need to put it in a trench. The cable is reinforced in several layers by an even coil of wire, each layer having a winding direction different from the previous one. As a result, the mass of one kilometer of such a cable reaches several tons. But aluminum cannot be used because in seawater it would react with the formation of hydrogen and this would be detrimental to the optical fibers.

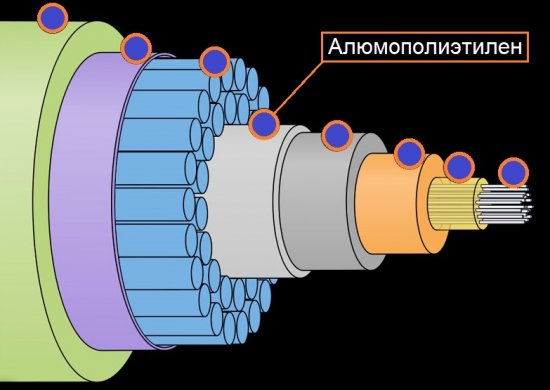

But aluminum polyethylene follows the steel reinforcement, it goes as a separate layer of shielding and waterproofing. Aluminopolyethylene is a composite material of aluminum foil and polyethylene foil glued together. This layer is almost invisible in a large volume of the cable structure, since its thickness is only about 0.2 mm.

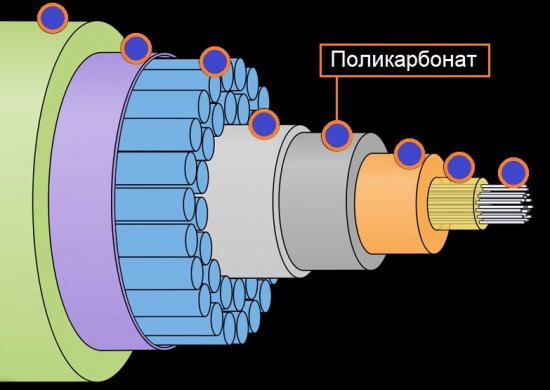

In addition, to further strengthen the cable, there is a layer of polycarbonate. It is strong enough while being light. With polycarbonate, the cable becomes even more resistant to pressure and impact, it is no coincidence that polycarbonate is used in the production of protective helmets. Among other things, polycarbonate has a high coefficient of thermal expansion.

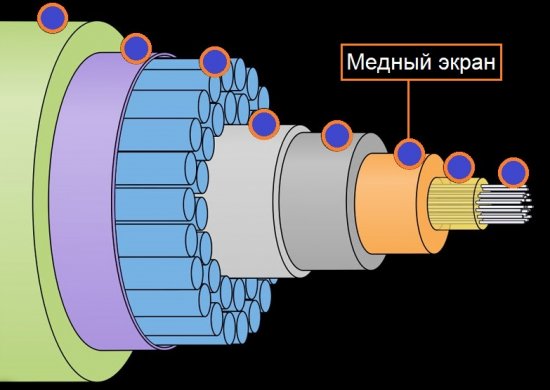

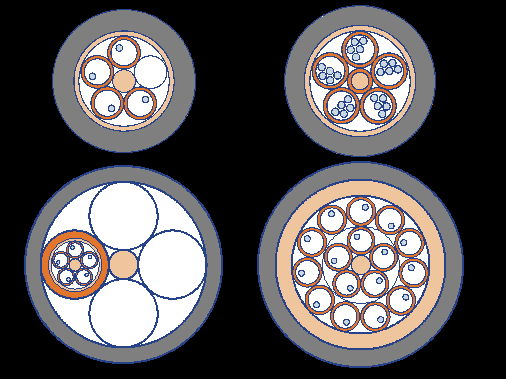

Underneath the polycarbonate layer is a copper (or aluminum) pipe. It is part of the cable core structure and acts as a shield. Inside this tube are directly copper tubes with closed optical fibers.

The number and configuration of optical fiber tubes for different cables can be different, if necessary, the tubes are properly intertwined. The metal parts of the structure serve here to power the regenerators, which restore the shape of the optical pulse, which is inevitably distorted during transmission.

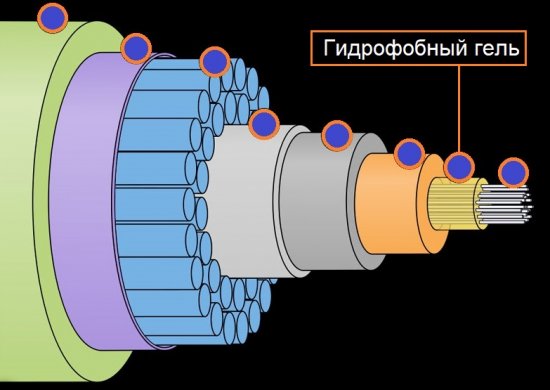

A hydrophobic thixotropic gel is placed between the tube wall and the optical fiber.

The production of deep-sea fiber optic cables is usually located as close to the sea as possible, most often near the port, since such a cable weighs many tons, while it is better to assemble it from the longest possible pieces, at least 4 kilometers each (the weight of such a piece is 15 tons !!!).

Transporting such a heavy cable over a long distance is not an easy task. For land transportation, twin rail platforms are used so that the entire piece can be rolled up without damaging the fibers inside.

Finally, the cable cannot simply be thrown from the ship—into the water. Everything must be cost-effective and safe. First they get permission to use coastal waters from different countries, then license to work, etc.

Then they conduct geological surveys, assess seismic and volcanic activity in the laying area, look at the forecasts of meteorologists, calculate the probability of underwater landslides and other surprises in the area where the cable will lie.

They take into account the depth, the density of the bottom, the nature of the soil, the presence of volcanoes, sunken ships and other foreign objects that could interfere with the work or require the extension of the cable. Only after carefully calibrated details down to the smallest detail do they begin to load the cable onto ships and lay it.

The cable is laid continuously. It is transported through a bay on a ship to the spawning ground, where it sinks to the bottom. The machines unwind the cable at the correct speed while maintaining tension as the boat follows the route.If the cable breaks during installation, it can be hoisted aboard and repaired immediately.