Ways to protect the cable from mechanical damage

In populated areas and on the territories of enterprises, the electrical and information networks are, as a rule, wired. When cable only installed — it is clearly visible, but if the cable is laid for a long time, it is usually impossible to see, as it turns out to be hidden somewhere inside the structure. And as soon as earthworks or any kind of repair begins, the threat of damage to the hidden cable immediately arises.

To prevent this, the cable is protected from mechanical damage with special measures. Thus, the cable will be insured against violation of its integrity, as well as the entire structure to which it is connected - from interruptions in power supply, communications, in other words - from accidents.

There certainly is armored power cables, the shells of which appear to have been created to protect the internal wires from mechanical damage. But even the steel casing can lose if you put too much mechanical force on it, for example with an excavator bucket.In this case, the cable sheath is simply deformed, and the deformed sheath itself can easily break the integrity of the insulation and the wires themselves.

In order to secure the cable in advance from such tragedies, in those areas where construction or earthworks are most likely, and sometimes along the entire length of the line, protective structures are erected: pipes, mines, cable channels, etc. — depending on the material of the cable, the location of its course, voltage class, etc.

In everyday life, when laying a cable for its mechanical protection, plastic cable channels, plastic and metal pipes, corrugated pipes, metal hoses and special skirting boards for cables are used.

Each situation has its own category of means of protecting cables against mechanical damage.

Different protection for different cable lines

Underground protective means are used for cable routes laid (according to PUE 2.3.83) in places with probable earthworks at a depth of more than 1.2 meters, and the protection is not installed along the entire length of the cable, but only in vulnerable areas and on places where there is a high risk of exposing people to step voltage.

External protective equipment is used for cables laid on poles or on the walls of buildings. Typically, these cables include low current data cables or electrical cables.

If the cable is laid inside the wall, then internal protection is applied, which is also installed inside the wall along with the cable. In this case, construction, installation or repair work in the building will not damage the cable.

Underground cables are equipped not only with a protective metal sheath, but also require the use of a fairly thick layer of bulk materials, since underground cables are the most difficult to assemble, and in the event of a need for repair, the matter will lead to significant material costs.

Therefore, an underground cable is never placed in a hollow trench, it is installed at a certain distance from its wall, and if there are several cables, they maintain a certain distance between them. So, if the cable is damaged in one place, then the adjacent cable is unlikely to suffer and the damaged place, being located, can be repaired.

Cable protection materials

The most durable means of mechanical protection of cables are reinforced concrete slabs or brickwork. There may even be some structures or passageways above the underground line, these materials allow for that.

Metal shielding is usually used for unarmoured cables. Such protection is a solid or perforated construction, sometimes for multi-purpose purposes.

Polymeric materials are allowed only to protect internal cables, because outside they are at risk of the destructive effects of ultraviolet radiation, moisture, etc.

If the cable is fixedly installed deep underground or outside the building, where it is essentially not at risk of dynamic loading, asbestos and ceramic protective means are used. These materials are also useful for cables installed in harsh environments.

If people often go to the place where the cable runs, then the most acceptable standard metal protective structure, capable of slight deformation and high strength. But there is also a drawback — a tendency to corrosion. Therefore, metal armor requires regular monitoring.

Protective design

The largest protective structures for cables are underground tunnels (galleries, overpasses). Inside them there can be several dozen cables statically located on special clamps. In addition to cables, water, ventilation, sewage and other pipes can pass inside such a tunnel.

Inside buildings, mines are used to protect cables. The cable in the mine is not only protected, but also supported along its entire length.

Perforated trunking and ceiling plates are also suitable for protecting power, low current and data cables in buildings.

The section of the cable laid outside can be reliably protected by a metal or asbestos pipe. Sections of cables laid inside buildings are protected by polymer pipes. These pipes are often corrugated, which allows not only to safely pull the cable through the opening, but also to give the cable and its sheath a curved shape along the cable path.

When the cable just needs to be physically protected, if it is in a non-aggressive environment and there is not much dynamic load, then it will become a tray made of solid or perforated material that serves as a kind of guide.

Special cable trays and channels are also used when installing cables in buildings:

Finally, to mark the laying of the underground cable, signal strips are used. These cassettes, by their presence, indicate to the excavation workers that there is a cable here.

Requirements for the elements of protection and its implementation

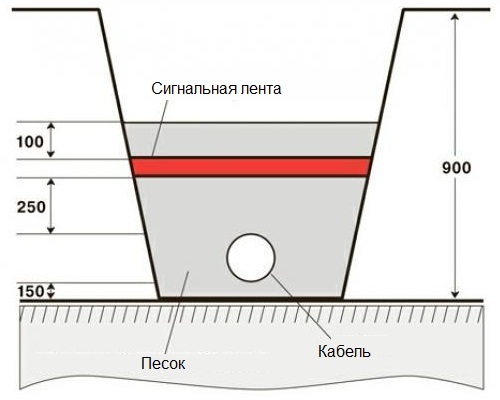

Underground cables must be protected more reliably. This requires a sand (or similar) cushion on which the slabs are then laid. If the voltage of the protected line is more than 35 kV, then the thickness of the plate less than 50 mm is unacceptable.

At a lower operating voltage, a baked clay brick without holes can be placed instead of a slab. Such solutions perform not only a protective, but also a signal function like a tape.

During installation, the cable is never stretched or twisted strongly, it is placed loosely so that deformation from changes in temperature and soil movement does not create dangerous tension.

When laid under a main road or even a dirt road, the cable is usually protected by a metal pipe. Steel or asbestos in this case will protect the cable in case of soil subsidence. Under these conditions, only one cable is always installed in one pipe, and if there are several cables, then there may be several pipes.

The protective signal tape is placed at least 250 millimeters from the cable insulation, and also protrudes at least 50 millimeters on each side above it. The tape is not laid over junctions and over connectors, so as not to interfere with repairs. The protective layer of bricks, unlike the tape, is laid in a certain way, depending on the width of the trench.

See also:Heat resistance and fire resistance of cables and wires, non-combustible insulation