Methods of routing a power cable

Laying the power cable in the ground (in trenches) is the most economical. For this, cables armored with steel strips with an outer cover of cable yarn are used. There cannot be more than six of them in one trench. The clear distance between the cables should be from 100 to 250 mm. If the cables belong to different organizations, this distance increases to 0.5 m.

Laying the power cable in the ground (in trenches) is the most economical. For this, cables armored with steel strips with an outer cover of cable yarn are used. There cannot be more than six of them in one trench. The clear distance between the cables should be from 100 to 250 mm. If the cables belong to different organizations, this distance increases to 0.5 m.

The depth of the cable with a voltage of up to 35 kV from the planning mark should be at least 0.7 m, and when crossing roads - 1 m, but not less than 0.5 m from the bottom of the drainage ditch. If these distances cannot be maintained, then the cables are laid in pipes or separated from each other with a fireproof partition.

Distances (dimensions) from cable lines to engineering structures and site locations are normalized. For example, it is not possible to place cables closer than 0.6 m from the foundations of buildings; 0.5 ... 1 m — from pipelines; 2 m — from the heating network; 3 ... 10 m — from the railways; 1 m — from road ditches; 10 m — from the axis of the outermost wire and from the support of the overhead line above 1 kV; 1 m — from the support of the overhead line to 1 kV, etc.

Distances (dimensions) from cable lines to engineering structures and site locations are normalized. For example, it is not possible to place cables closer than 0.6 m from the foundations of buildings; 0.5 ... 1 m — from pipelines; 2 m — from the heating network; 3 ... 10 m — from the railways; 1 m — from road ditches; 10 m — from the axis of the outermost wire and from the support of the overhead line above 1 kV; 1 m — from the support of the overhead line to 1 kV, etc.

If the cables intersect with engineering structures, then, starting from the size, mechanical protection of the cables is installed. Most often, this cable is laid in pipes. These pipes must be able to replace the cables without disturbing the normal operation of the structure crossed by the line.

If the cables are laid before the erection of the structure, then empty pipes for new cables are laid next to them when the existing ones are damaged.

If the cables are laid before the erection of the structure, then empty pipes for new cables are laid next to them when the existing ones are damaged.

In cases where it is impossible to withstand the dimensions, as well as under a permanent improved coating, the cables are laid in pipes and blocks. This is the most economical way to run cables. The blocks are made of asbestos-cement concrete and ceramic pipes or of special prefabricated reinforced concrete structures.

Blocks provide 10% of spare pipes or ducts, but not less than one. When turning the track and at the transition points, more than 10 cables in the ground are arranged with special wells. The same wells are arranged on straight sections of pipes or blocks. The distance between them depends on the permissible force when pulling the cable.

Unarmored cables with a thickened lead hermetic sheath (eg SGT) are laid in blocks longer than 50 m. Armored cables without external covers can be used for sections up to 50 m long.

A line with more than six cables must be laid in ducts; and more than 20 in tunnels. Movable plates are placed on top of the channels. Outside buildings and in explosive installations, the channels are covered with sand or earth.

In channels with a depth of up to 0.9 m, the cables can be placed from below; in deeper channels and tunnels — on cable structures.The height of the tunnel should be at least 1.5 ... 1 m, and the passage between the structures should be at least 1 m. It is possible to locally narrow the passages up to 0.8 m with a length of up to 0.5 m. Automatic fire extinguishers and smoke alarm. To prevent water from entering the tunnel, automatic drainage mechanisms etc. are carried out.

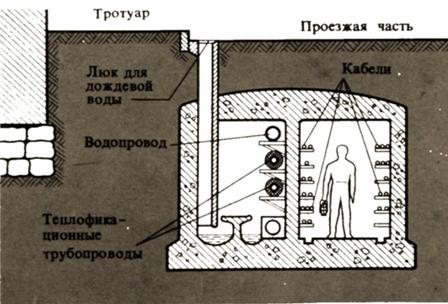

Tunnels where, in addition to cables, there are other communications (water supply, heating network, etc.) are called collectors.

Unarmored cables are allowed in all cable structures (tunnels, ducts, collectors). Armored cables with a non-combustible coating must be used in switchgear. Protective covers made of combustible fibrous materials are not allowed on cables laid in structures. To prevent corrosion and better heat transfer, the armor is painted black.

Unarmored cables are allowed in all cable structures (tunnels, ducts, collectors). Armored cables with a non-combustible coating must be used in switchgear. Protective covers made of combustible fibrous materials are not allowed on cables laid in structures. To prevent corrosion and better heat transfer, the armor is painted black.

Support structures for laying cables are installed every 0.8 ... 1 m. Between non-armored cables with a metal hermetic sheath and support (fastening) structures, a glass package, roofing felt, etc. are laid. soft materials.

In industrial premises, cables are laid in such a way that they are accessible for repair and exposed, for example, on trays, for inspection. In places where mechanical damage is possible, as well as everywhere at a height of up to 2 m, the cables are protected. In floors and intermediate floors, the cables are laid in pipes or ducts. Installation of cables in building structures ("monolithic") is not allowed.

The rest of the wiring in industrial premises is similar to cable wiring. The difference is that in this case not only armored cables are used, but also armored cables without protective covers made of combustible materials.In addition, the cross section of the cables is not limited. A cable laid under water, for example, at the junctions of rivers, canals, bays, etc. they are chosen in areas with bottoms and shores that are not very susceptible to erosion. Cables are buried at 0.5 ... 1 m. Underwater obstacles are bypassed or equipped with trenches and passages.

The rest of the wiring in industrial premises is similar to cable wiring. The difference is that in this case not only armored cables are used, but also armored cables without protective covers made of combustible materials.In addition, the cross section of the cables is not limited. A cable laid under water, for example, at the junctions of rivers, canals, bays, etc. they are chosen in areas with bottoms and shores that are not very susceptible to erosion. Cables are buried at 0.5 ... 1 m. Underwater obstacles are bypassed or equipped with trenches and passages.

Cables crossing streams, their floodplains and drainage ditches are placed in pipes embedded in the ground. In this case, the same cables are used as for laying in the ground.

Without pipes, the cables are laid underwater in a lead jacket with an armor of flat or round wires with an outer protective coating. Cables with rubber (plastic) insulation and hermetically sealed vinylite sheath. Cables with paper-oil insulation and aluminum hermetic sheath are not suitable for underwater laying.

When crossing rivers with fast currents, it is necessary to use cables with a double armor of round wires, which can well take significant tensile loads. It is allowed to cross non-navigable and non-flowing rivers with a slow current on cables with ribbon armor. The exit of the cable from the water is carried out with a margin of 10 ... 30 m in pipes, in wells.

When draining peat bogs, for cable laying, a line of neutral soils is poured 1.5 m in both directions from the end cables. There must be at least 0.3 m of soil under and above the cable. Small water depressions can be filled with earth or cross piles with or without pavement. It is possible to lay the cable in pipes, blocks or closed trays above the marsh 0.3 m above the water level. All these structures are attached to piles.

When draining peat bogs, for cable laying, a line of neutral soils is poured 1.5 m in both directions from the end cables. There must be at least 0.3 m of soil under and above the cable. Small water depressions can be filled with earth or cross piles with or without pavement. It is possible to lay the cable in pipes, blocks or closed trays above the marsh 0.3 m above the water level. All these structures are attached to piles.

A number of adverse factors operate in permafrost regions: cracks, depressions, sinkholes, landslides, etc.Cables are laid in these areas, as well as in deep seasonal freezing underground: in trenches (up to 4 cables), in embankments, cable trays, channels and collectors; or above ground; open on the surface (by air suspension), in protective boxes, on overpasses, in galleries, on the walls and structures of engineering structures and under permanent footbridges.

Trenches are arranged in rocks (at a depth of at least 0.4 m), dry sands and other soils with minor frost cracks and few depressions. In other cases, in the trenches, it is necessary to use cables with an aluminum hermetic sheath and the most durable armor of flat wires (AP, AAP).

Cables with tape armor are allowed when carrying out a number of measures to combat uneven soil heave and frost cracks: embankment, backfilling of trenches with sandy or gravel-rocky soil, installation of drainage ditches or slots, seeding of cable route with grasses or planting shrubs and snow retention. All this is very expensive and time consuming.

In areas with active development of mounds, elevations and landslides, the cables are not laid directly in the ground at all. Channels and underground cable channels are waterproofed.

The overhead laying of cables with their number up to 20 is carried out on wooden, and more than 20 - on reinforced concrete overpasses. In particularly difficult conditions (permafrost, polar night and low temperatures), the cables are laid on the side surfaces of the channels of heating networks, water supply systems and other devices.

I. I. Meshteryakov