Wires and cables of overhead power lines

On air lines power transmission voltage above 1000 V, bare wires and cables are used. Being outdoors, they are exposed to the atmosphere (wind, ice, temperature changes) and harmful impurities from the surrounding air (sulfur gases from chemical plants, sea salt) and therefore must have sufficient mechanical strength and be resistant to corrosion (rust ).

On air lines power transmission voltage above 1000 V, bare wires and cables are used. Being outdoors, they are exposed to the atmosphere (wind, ice, temperature changes) and harmful impurities from the surrounding air (sulfur gases from chemical plants, sea salt) and therefore must have sufficient mechanical strength and be resistant to corrosion (rust ).

At present, steel-aluminum conductors have found the greatest application in overhead lines.

Previously, copper wires were used on overhead lines, and now aluminum, steel-aluminum and steel are used, and in some cases, wires of special aluminum alloys — eldrium, etc. Lightning protection cables are usually made of steel.

They are distinguished by design:

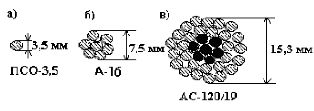

a) multi-core conductors of one metal, consisting (depending on the cross-section of the conductor) of 7; 19 and 37 separate wires twisted together (Fig. 1, b);

a) multi-core conductors of one metal, consisting (depending on the cross-section of the conductor) of 7; 19 and 37 separate wires twisted together (Fig. 1, b);

b) single-wire wires consisting of one solid wire (Fig. 1, a);

c) stranded conductors of two metals — steel and aluminum or steel and bronze.Steel-aluminum conductors of conventional design (class AC) consist of a galvanized steel core (single-wire or twisted of 7 or 19 wires), around which an aluminum part is located, consisting of 6, 24 or more wires (Fig. 1 , ° C).

Rice. 1. Construction of wires of overhead lines: a — single-wire wires; b — stranded conductors; c — steel-aluminum wires.

The structural design data of bare aluminum and steel-aluminum conductors are in GOST 839-80.

See also: Bare wire structures for overhead power lines

The selection of air lines involves consideration of several factors, among which one of the most significant is prolonged heating with electric current. Heating of the wires limits the transmission capacity of the overhead line, leads to corrosion of the wires, their loss of mechanical strength, increase in sag, etc. The temperature of the conductors depends on the current load and the weather conditions of the overhead line route.

The load-carrying capacity of wires is greatly affected by weather conditions—wind speed, ambient temperature, and solar radiation, which vary widely throughout the year.

A change in wind speed is said to have a greater impact than a change in air temperature. A weak wind with a speed of 0.6 m / s increases the throughput of wires by 140% compared to static air conditions, while an increase in ambient temperature by 10 ° C reduces it by 10-15%.

Copper wires

My wires, made of tightly drawn copper wire, have low resistance (r = 18.0 Ohm x mm2/ km) and good mechanical strength: maximum tensile strength sp = 36 ... 40 kgf / mm2, successfully resist atmospheric influences and corrosion from harmful impurities in the air.

Copper wires are marked with the letter M with the addition of the nominal cross-section of the wire. So, copper wire with a nominal cross-section of 50 mm2 marked with M — 50.

Currently, copper is a scarce and expensive material, which is why it is practically not used as conductors for overhead power lines. To save copper, copper, bronze and steel-bronze conductors were discontinued in the 1960s.

Aluminum wires

Aluminum wires differ from copper wires with much lower mass, slightly higher specific resistance (r = 28.7 ... 28.8 Ohm x mm2/ km) and less mechanical strength: sp = 15.6 kgf / mm2 — for wires of AT class wires and sp = 16 … 18 kgf / mm2 of Atp wire.

Aluminum wires differ from copper wires with much lower mass, slightly higher specific resistance (r = 28.7 ... 28.8 Ohm x mm2/ km) and less mechanical strength: sp = 15.6 kgf / mm2 — for wires of AT class wires and sp = 16 … 18 kgf / mm2 of Atp wire.

Aluminum wires are mainly used in local networks. The low mechanical strength of these wires does not allow high voltage. To avoid large arrows and secure the necessary PUE the minimum size of the line to the ground, it is necessary to reduce the distance between the supports and this increases the cost of the line.

In order to increase the mechanical strength of aluminum wires, they are made of multi-stranded, hard-drawn wires. Well tolerant of atmospheric influences, aluminum wires do not withstand the impact of harmful impurities from the air.

Therefore, for overhead lines built near seashores, salt lakes and chemical plants, AKP brand aluminum conductors protected against corrosion (aluminum corrosion resistant, with filling of the space between the conductors with neutral grease) are recommended. Aluminum conductors are marked with the letter A with the addition of the nominal cross-section of the conductor.

Steel wires

Steel wires have high mechanical strength: maximum breaking strength sp = 55 ... 70 kgf / mm2... Steel wires are single-wire or multi-wire.

The electrical resistance of steel wires is much higher than that of aluminum, and in AC networks it depends on the amount of current flowing through the wire. Steel wires are used in local networks with a voltage of up to 10 kV when transmitting relatively low power, when the construction of lines with aluminum wires is less profitable.

A significant disadvantage of steel wires and cables is their susceptibility to corrosion. To reduce corrosion, the wires are galvanized. There are two brands of stranded steel wire available: PS (steel wire) and PMS (copper steel wire). PS wires have a copper addition of up to 0.2%, and PSO wires are made with a diameter of 3; 3.5; 5 mm. Steel multi-wire cable lightning protection cables are produced in grades S-35, S-50 and S-70.

Steel-aluminum wires

Steel-aluminum conductors have the same resistance as aluminum conductors of the same cross-section, because in the electrical calculations of steel-aluminum conductors, the conductivity of the steel part is not taken into account due to its insignificance compared to the conductivity of the aluminum part of the conductors.

Structural steel wires make up the inside of the steel aluminum wire, and aluminum wires make up the outside. Steel is designed to increase mechanical strength, aluminum is a conductive part.

With steel-aluminum wires, additional internal stresses occur in the aluminum part of the wire, due to the different coefficients of thermal expansion of aluminum and steel.

Mandatory wire stress limitation at the average annual temperature for all conductors is necessary to prevent rapid fatigue wear of the conductors due to vibration.

It was experimentally established that aluminum begins to lose its strength properties at temperatures above 65 ° C. Taking this into account, when choosing the maximum operating temperature of steel-aluminum wires, it is recommended to plan a reduction in the strength of aluminum by 12 — 15 % (which is 7 — 8% loss of strength of the wire as a whole) ) throughout their service life, which approximately corresponds to continuous operation of the wire for 50 years at a temperature of 90 ° C. It should be noted that the total loss of mechanical strength due to short-term emergency overloads of the wires does not exceed 1%.

The following brands of steel-aluminum wires (GOST 839-80) are produced:

AC - wire consisting of a core - galvanized steel wires and one or more outer layers of aluminum wires. The wire is intended for laying on land, except in areas with polluted air with harmful chemical compounds;

AC - wire consisting of a core - galvanized steel wires and one or more outer layers of aluminum wires. The wire is intended for laying on land, except in areas with polluted air with harmful chemical compounds;

INQUIRY, ASKP — similar to AC brand wire, but with the steel core (C) or entire wire (P) filled with grease that counteracts the occurrence of wire corrosion. Designed for laying along the coast of seas, salt lakes and in industrial areas with polluted air;

ASK — same as ASK wire, but with a steel core insulated with a plastic sheath. In the marking of the wire, after the letter A, there may be the letter P, which indicates that the wire has increased mechanical strength (for example, APSK).

Steel-aluminum wires of all brands are produced with a different ratio of the cross-section of the aluminum part of the wire to the cross-section of the steel core: within 6.0 ... 6.16 - for the operation of the wire in medium mechanical load conditions; 4.29 ... 4.39 — reinforced strength; 0.65 … 1.46 — particularly reinforced strength: 7.71 … 8.03 — light construction and 12.22 … 18.09 — particularly light.

Light wires are used on newly built and reconstructed lines in areas where the thickness of the ice wall does not exceed 20 mm. Reinforced steel-aluminum conductors are recommended for use in areas with ice wall thickness greater than 20 mm. Special strong wires are used for the implementation of long distances in crossings through water spaces and engineering structures.

For a more complete characterization of steel-aluminum conductors, the nominal cross-section of the conductor and the cross-section of the steel core are entered in the designation of the wire brand, for example: AC-150/24 or ASKS-150 /34.

Aldrei wires

Aldry wires have about the same electrical resistance as aluminum wires, but have greater mechanical strength. Aldry is an aluminum alloy with minor amounts of iron («0.2%), magnesium (» 0.7%) and silicon («0.8%); in terms of corrosion resistance, it is equal to aluminum. The disadvantage of Aldrey wires is their low resistance to vibration.

Location of overhead line wires

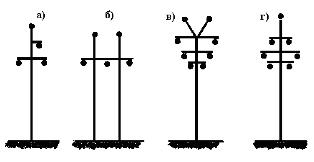

The conductors on the supports of overhead lines can be placed in different ways: on single-circuit lines — in a triangle or horizontally; on lines with a double chain — reverse tree or hexagon (in the form of a «barrel»).

Arrangement of wires in a triangle (Fig. 2, a) is used on lines with a voltage of up to 20 kV, including on lines with a voltage of 35 ... 330 kV with metal and reinforced concrete supports.

The horizontal arrangement of wires (Fig. 2, b) will be used on lines 35 ... 220 kV with wooden supports. This arrangement of wires is the best from the point of view of working conditions, as it allows the use of lower supports and excludes wire entanglement during ice descent and wire dancing.

On lines with two values, the wires are placed either with a reverse tree (Fig. 2, c), which is convenient for the installation conditions, but increases the mass of the supports and requires the suspension of two protective cables or a hexagon (Fig. 2, G).

The latter method is preferable.It is recommended for use on two-valued lines with a voltage of 35 ... 330 kV.

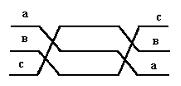

All these options are characterized by an asymmetric arrangement of wires relative to each other, which leads to a difference in the electrical parameters of the phases. For the equation of these parameters, transposition of wires is used, i.e. the mutual location of the conductors relative to each other on different sections of the line is changed successively on the supports. In this case, the conductor of each phase passes one third of the length of the line in one place, the second in the other and the third in the third place (Fig. 3.).

Rice. 2. Arrangement of wires and protective cables on the supports: a — with a triangle; b — horizontal; c — reverse tree; d — hexagon (barrel).

Rice. 3… Single-wire line transposition scheme.

The calculation of the mechanical part of the overhead line is carried out based on the repeatability of the wind speed and the thickness of the ice wall on the wires, which meets the requirements for reliability and capitalization of a certain class of overhead lines.

Overhead lines of different classes, when crossing the same terrain, especially on a common route, must be designed for different wind and ice loads.

Lightning protection cables of overhead power lines

Lightning protection cables are suspended above the wires to protect them from atmospheric surges. On lines with a voltage below 220 kV, cables are hung only at the approaches to substations. This reduces the likelihood of overlapping wires near the substation. On lines with a voltage of 220 kV and above, the cables are suspended along the entire line. Steel ropes are usually used.

Previously, the cables of lines of all rated voltages were grounded tightly on each support. Operational experience shows that currents appear in the closed circuits of the grounding system — cables — supports. They arose as a result of the action of the EMF induced in the cables by electromagnetic induction. At the same time, in a number of cases significant power losses occur in repeatedly grounded cables, especially in ultra-high voltage lines.

Studies have shown that by suspending cables with increased conductivity (steel-aluminum) on insulators, the cables can be used as communication wires and as current conductors to supply low-power consumers.

In order to provide an adequate level of lightning protection to the lines, the cables must be connected to the ground through spark gaps.