Determining the cause of an electrical injury, determining the factors that determine the severity of an electrical injury

The damage that lower identification of the causes of individual electrical injuries does to the fight against electrical injuries has been repeatedly discussed. The main prerequisites for this (besides the fear of liability for an accident) are an insufficiently clear idea of what the causes of electrical injuries are, what they are, as well as attempts to identify the main cause - technical or organizational - and the inevitable subjectivity in solving this issue.

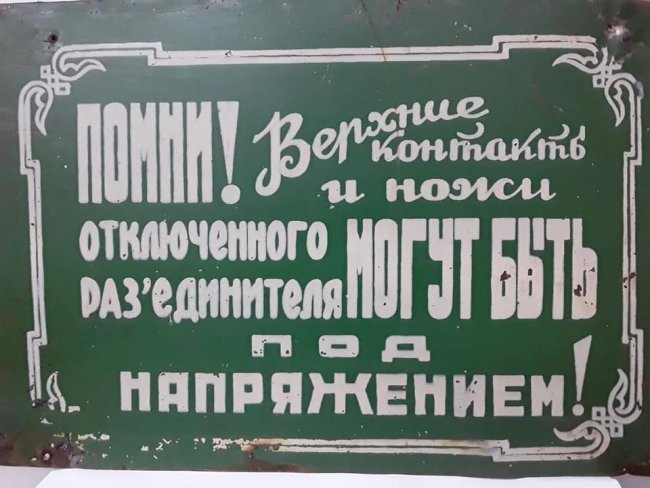

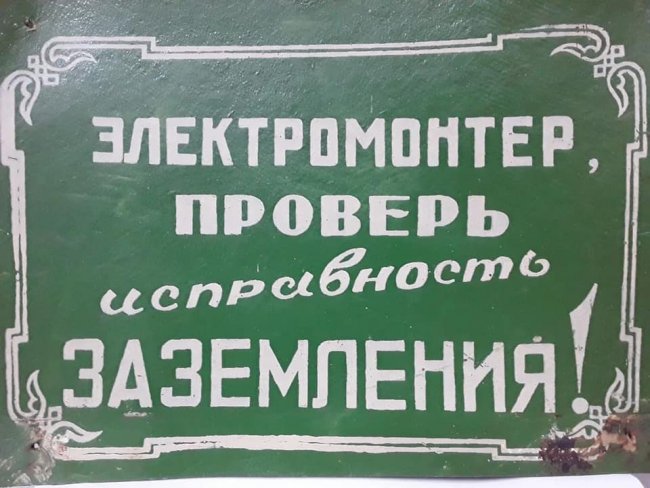

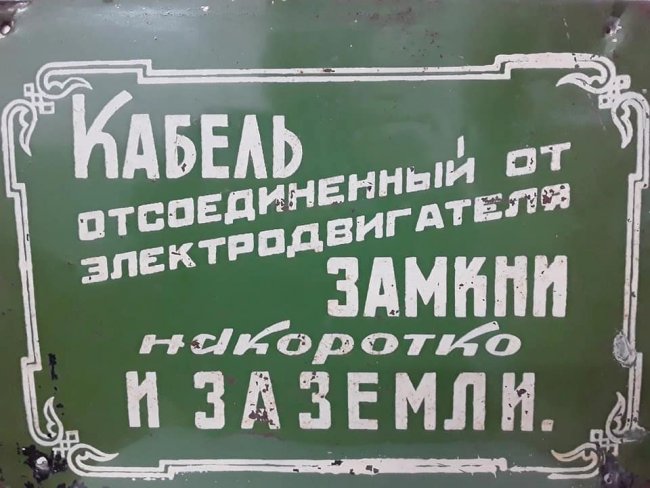

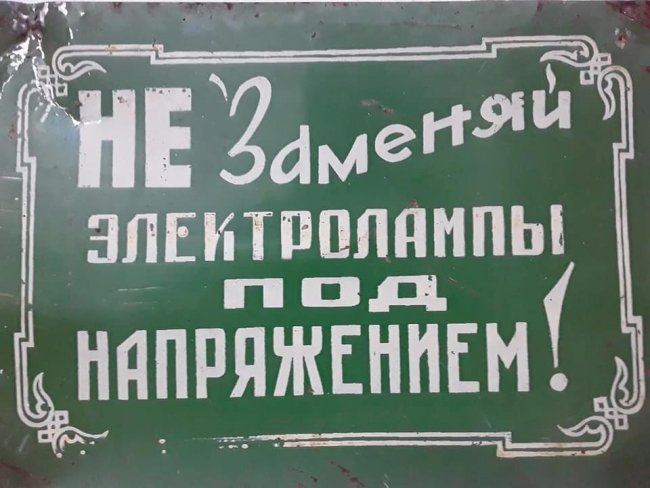

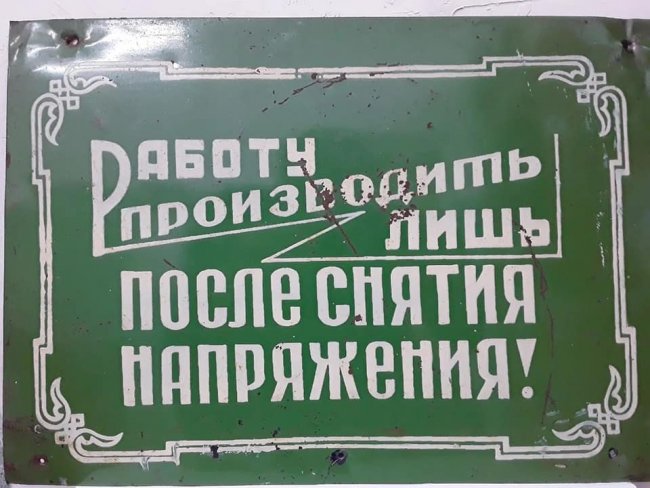

The article uses for illustrations old electrical safety signs from the 1950s from the workshop of an industrial enterprise.

Often "accidental contact with live parts" is cited as the sole cause of electrical injury. But in a sense, all such touches (except intentional ones) are accidental. So explain electrical injuries merely by an accidental touch is as wrong as to say that they are not due to some other cause.

For a comprehensive investigation of electrical injuries, the clear classification of the causes of individual injuries and the possibility of their disclosure at the stage of accident investigation is of great importance. It is recommended to identify four groups of reasons at the investigation stage: technical, organizational and technical, organizational and organizational and social.

Classification of the causes of electrical injuries

For technical reasons, we will include defects in the design, manufacture and installation of electrical installations, the absence or imperfection of protective equipment and devices, as well as the non-compliance of the type of installations, protective means and devices with the conditions of use.

Organizational and technical reasons mean technical defects in the operation and repair of electrical installations, protective equipment and devices, untimely and poor quality repair of electrical installations, protective equipment and devices, lack or unsatisfactory maintenance of technical documentation.

Organizational and technical reasons also include the use of electrical installations for other purposes, for example, for storing various things, drying clothes, etc., the use of installations that have not been put into operation according to the established procedure, untimely replacement of defective or outdated installations as well as violation air lines of the security area.

Organizational causes of electrical injuries include unsatisfactory management of electrical equipment and non-observance of organizational and technical measures provided for in the rules to ensure safety during all types of work.

The organizational and social causes of industrial electrical injuries are currently: inadequate training of electrical personnel and inadequate electrical safety instructions for workers in non-electrical occupations, as well as mismatch of work to the task (including unauthorized work in electrical installations).

The organizational and social causes of industrial electrical injuries also include overtime, non-compliance with the work in the specialty, violation of production discipline, as well as allowing persons under 18 years of age or with medical contraindications to such work to work in electrical installations.

Organizational and social reasons are also inherent in non-production electrical injuries. They include, for example, the inconsistency of the nature of the victim's activity with his professional training, performing any work while intoxicated, leaving children unattended, unsatisfactory (from the point of view of electrical safety) living conditions, ignorance of the rules for using electricity and the danger of electric current.

In order to correctly establish the causes of electrical injury, one must be guided by official documents on electrical safety (rules, norms, instructions), labor legislation and other legal regulations establishing the rights and obligations of citizens, as well as electrical injury cards.

Determining factors determining the severity of electrical injuries

The factors on which the results of electric current exposure depend on a person (voltage at touch, path and frequency of the current, etc.) have until recently been studied only in laboratory conditions and exclusively on animals.

Meanwhile, a significant part of the information necessary for the study of these factors, and moreover, quite objective, can be obtained at the stage of investigation of electrical injuries.

These are the sex and age of the victim, the presence of medical contraindications, the conclusion of the forensic medical examination, the nominal voltage, the frequency of the current and the neutral mode of the electrical installation on which the injury was received, the characteristics of the electric shock current circuit, the state of the external environment (air temperature and humidity, noise, illumination, concentration of harmful substances in the air of the working area, characteristics of the premises with regard to the danger of electric shock) — all information is provided by the maps of electrical injuries.

The value of the impulse current, mA, can be determined by the following formula:

Azhora = (UNC/Zhora) 103

where Unp is the touch voltage, V; Zchel is the resistance of the human body, Ohm.

This formula can be used when it is possible to measure the contact voltage (in the study of electrical injuries in installations with a voltage of up to 1 kV) or when such intentions are necessary (study of electrical injuries caused by step voltage or «performed» potential).

When performing such measurements, appropriate precautions must be taken, therefore they can only be entrusted to personnel authorized to perform such measurements.

To calculate the current, you need to know the resistance of the human body. For approximate calculations, you can be satisfied with the formula:

Azhora = (kUnomer /Zhora) 103

where k is a coefficient that takes into account the nature of human contact with electrically dangerous elements - single-phase, two-phase, etc.

When touching a two-phase three-phase installation, as well as when touching a phase and: zero (ground, grounded frame of a single-phase installation) k = 1 when touching a single-phase three-phase installation k = 0.58 and Zpeople are taken equal to 1000 ohms

It is possible to estimate with an accuracy of tenths of a second the time spent by a person under current, if his contact with an electrically dangerous element triggers the automatic protection (circuit breakers, fuses, RCDs, etc.).

In other cases, this important parameter can be approximately determined only in the course of the investigation of an electrical injury, but according to the data of a medical examination or according to the testimony of witnesses of the accident.

Development of measures to prevent repetitive electrical injuries

An industrial accident is an emergency situation and a signal that not everything is going well with labor protection in the enterprise.Therefore, the investigation of accidents also has the positive meaning of being the reason for a serious check of the quality of all prescribed rules: safety measures, not only those that led to the case under investigation, in the whole enterprise or in the workshop, and not only on site .incidents.

For example, if the incident was caused by the lack of a lock on the door of a power cabinet, the investigation committee will usually indicate the need to check the locking devices of all such cabinets.

If the victim is not on time safety briefed, then it is suggested to check the date of the last instruction for all employees of this profession, etc. Such activities are certainly useful and can be carried out by the enterprise itself.

Earlier, in the electrical injury investigation materials, there were vague proposals to remedy the causes of the accident, such as "require store management to take measures to comply with the PTB." Now such formulations are not used, but sometimes they are limited to measures, the implementation of which depends on the specified services, and not on the higher authorities.

There are almost no measures, the implementation of which requires improvement of material and technical supply, automation of dangerous processes, removal from production of unreliable equipment, etc.

This is partly due to the lack of sufficient arguments for presenting such proposals (one accident is not yet a reason for generalizations), as well as the fear of "misleading" the administration, which may face difficulties in implementing them.

For example, based on a single fact of a pump failure, it is still impossible to conclude that all pumps are unreliable (for this, it is necessary to analyze not one pump failure, but a set of such cases).

In general, the high quality of measures to prevent recurrent injuries should be noted with satisfaction. They are logical, specific and address the root causes of the injury. This is due to technical labor inspectors, energy inspectors and other participants in the investigation. The issue is the full implementation of the planned activities.