Thin film solar cells

Up to 85% of solar cells on the market today are crystalline solar modules. However, experts assure that the thin-film technology for the production of solar cells turns out to be more efficient and therefore the most promising of the already known crystal modules.

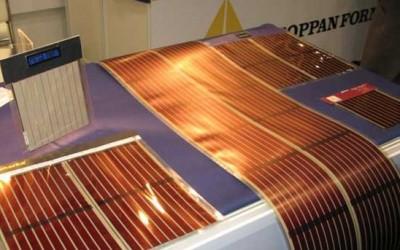

The main advantage of thin-film technology is its low cost, which is why it has every chance to become a leader in the coming years. The modules of the new base make solar panels flexible, in the literal sense of the word. They are light and flexible, which allows you to place such batteries on literally any surface, including the surface of clothing.

Flexible solar cells are based on polymer films, amorphous silicon, aluminum, cadmium telluride and other semiconductors, which are already used in the production of portable chargers for mobile phones, laptops, tablets, video cameras and other gadgets, in the form of small foldable solar cells . But if more power is required, then the area of the module will have to be larger.

The first samples of thin-film solar cells were made with amorphous silicon deposited on a substrate, and the efficiency was only 4 to 5%, and the service life was not long. The next step of the same technology was to increase the efficiency to 8% and extend the service life, it became comparable to its crystal predecessors. Finally, the third generation of thin-film modules already had an efficiency of 12%, which is already a significant advance and competitiveness.

The indium copper selenide and cadmium telluride used here have made it possible to create flexible solar cells and portable chargers with an efficiency of up to 10%, and this is already a significant achievement, considering that physicists are fighting for every additional percentage of efficiency. Now let's take a closer look at how thin film batteries are made.

As for cadmium telluride, it began to be studied as a light-absorbing material back in the 1970s, when it was necessary to find the best option for use in space. To this day, cadmium telluride remains the most promising for solar cells. However, the question of cadmium toxicity remains open for some time.

As a result of the research, it was shown that the danger is minimal, the level of cadmium released into the atmosphere is not dangerous. The efficiency is 11%, while the price per watt is a third lower than that of silicon analogues.

Now for copper indium selenide. A significant amount of indium today is used to create flat panel monitors, so indium is nevertheless replaced by gallium, which has the same properties for solar energy… Film batteries on this basis achieve an efficiency of 20%.

Recently, polymer panels have begun to be developed.Here, organic semiconductors serve as light-absorbing materials: carbon fullerenes, polyphenylene, copper phthalocyanine, etc. The thickness of the solar cell is 100 nm, but the efficiency is only 5 to 6%. But at the same time, production costs are quite low, films are affordable, light and completely environmentally friendly. For this reason, resin panels are popular where environmental friendliness and mechanical flexibility are important.

So the efficiency of thin film solar cells produced today:

-

Single crystal — from 17 to 22%;

-

Polycrystal — from 12 to 18%;

-

Amorphous silicon — 5 to 6%;

-

Cadmium telluride — from 10 to 12%;

-

Copper-indium selenide — from 15 to 20%;

-

Organic polymers — 5 to 6%.

What are the characteristics of thin film batteries? First of all, it is worth noting the high performance of the modules even in diffused light, which gives up to 15% more power during the year compared to crystal analogues. Next comes the manufacturing cost advantage. In high-power systems, from 10 kW, thin-film modules show greater efficiency, although 2.5 times more area is needed.

Thus, we can name the conditions when thin-film modules gain a justified advantage. In regions with mostly cloudy weather, thin film batteries will work efficiently (diffuse light). For regions with hot climates, thin films are more efficient (they work just as effectively at high temperatures as at low temperatures). Possibility of use as decorative design solutions for finishing the facades of buildings. Transparency up to 20% is possible, which again plays into the designers' hands.

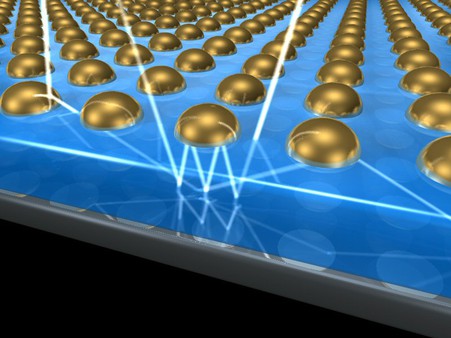

Meanwhile, in 2008, the American company Solyndra proposed placing thin-film batteries on cylinders, where a layer of photocell is applied to a glass tube that is placed inside another tube equipped with electrical contacts. The materials used are copper, selenium, gallium, indium.

The cylindrical design allows more light to be absorbed, and a set of 40 cylinders fits per meter of two panels. The highlight here is that the white roof coating contributes to the high efficiency of such a solution, because then the reflected rays also work, adding 20% of their energy. In addition, the cylindrical sets are resistant even to strong winds with gusts of up to 55 m / s.

Most solar cells manufactured today contain only one pn junction, and photons with energy less than the band gap simply do not participate in generation. Then scientists came up with a way to overcome this limitation, cascade elements of a multilayer structure were developed, where each layer has its own band width, that is, each layer has a separate pn junction with an individual value of the energy of the absorbed photons.

The upper layer is formed from an alloy based on hydrogenated amorphous silicon, the second — a similar alloy with the addition of germanium (10-15%), the third — with the addition of 40 to 50% germanium. Thus, each successive layer has a gap narrower than that of the previous layer, and the unabsorbed photons in the upper layers are absorbed by the underlying layers of the film.

In this approach, the cost of generated energy is halved compared to traditional crystalline silicon cells. As a result, an efficiency of 31% was achieved with a three-pass film, and a five-pass film promises all of 43%.

Recently, specialists from Moscow State University have developed roll-type solar cells based on a polymer applied to a flexible substrate of organic material. The efficiency turned out to be only 4%, but such batteries can work even at + 80 ° C for 10,000 hours. These studies have not yet been completed.

Swiss scientists achieved an efficiency of 20.4% on a polymer basis, and indium, copper, selenium and gallium were used as semiconductors. Today, this is a record for elements on a thin polymer film.

In Japan, they achieved 19.7% efficiency in similar (indium, selenium, copper) sputter deposited semiconductors. And in Japan they started producing solar fabric, cloth solar panels were developed using cylindrical elements about 1.2 millimeters in diameter attached to the fabric. At the beginning of 2015, they planned to start the production of clothing and sunshades on this basis.

It is obvious that thin-film solar panels will finally become generally available to the population in the near future. It is not for nothing that so much research is being conducted around the world in order to reduce costs.