Hydrogen power plants — trends and prospects

Although nuclear power plants have long been considered very safe, the accident at Japan's Fukushima nuclear power plant in 2011 once again forced energy engineers around the world to think about possible environmental problems associated with this type of energy.

The governments of many countries, including a number of EU countries, have declared a clear intention to transfer their economies to alternative energy, sparing no investment, promising billions of euros for this industry over the next 5-10 years. And one of the most promising and environmentally safe types of such an alternative is hydrogen.

If coal, gas and oil do run out, then there is simply unlimited hydrogen in the oceans, although it is not stored there in its pure form, but in the form of a chemical compound with oxygen - in the form of water.

Hydrogen is the most environmentally friendly energy source. Obtaining, transporting, storing and using hydrogen requires expanding our knowledge of its interaction with metals.

There are many problems here.Here are just some of them that await their solution: the production of highly pure hydrogen isotopes using membrane filters (for example, from palladium), the creation of technologically advantageous hydrogen batteries, the problem of combating the hydrogen cost of materials, etc.

The environmental safety of hydrogen, compared to other traditional types of energy sources, no one doubts: the product of hydrogen combustion is again water in the form of steam, while it is completely non-toxic.

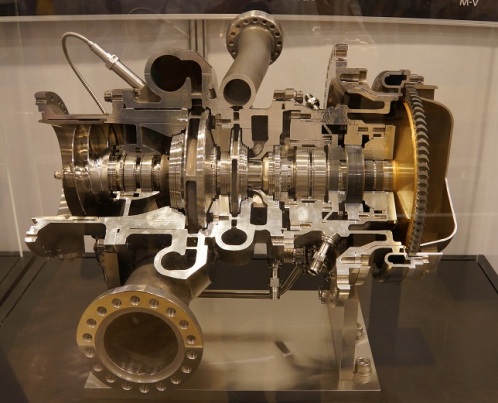

Hydrogen as a fuel can easily be used in internal combustion engines without fundamental changes, as well as in turbines, and more energy will be obtained than from gasoline. If the specific heat of combustion of gasoline in air is about 44 MJ / kg, then for hydrogen this figure is about 141 MJ / kg, which is more than 3 times higher. Petroleum products are also toxic.

Storage and transportation of hydrogen will not cause particular problems, the logistics are similar to that of propane, but hydrogen is more explosive than methane, so there are still some nuances here.

Hydrogen storage solutions are as follows. The first way is the traditional compression and liquefaction, when it will be necessary to ensure its ultra-low temperature to maintain the liquid state of hydrogen. This is expensive.

The second way is more promising — it is based on the ability of some composite metal sponges (highly porous alloys of vanadium, titanium and iron) to actively absorb hydrogen and, at low heating, release it.

Leading oil and gas companies such as Enel and BP are actively developing hydrogen energy today.A few years ago, the Italian Enel started the world's first hydrogen power plant, which does not pollute the atmosphere and does not emit greenhouse gases. But the main burning point in this direction lies in the following question: how to make the industrial production of hydrogen cheaper?

The problem is that electrolysis of water requires a lot of electricity, and if the production of hydrogen is put on stream precisely through the electrolysis of water, then for the economy in a single country this method of industrial production of hydrogen will be very expensive: three times, if not four times, in terms of equivalent heat of combustion from petroleum products. In addition, a maximum of 5 cubic meters of gas per hour can be obtained from one square meter of electrodes in an industrial electrolyzer. This is slow and economically impractical.

One of the most promising ways to produce hydrogen in industrial volumes is the plasma-chemical method. Here, hydrogen is obtained more cheaply than by electrolysis of water. In non-equilibrium plasmatrons, an electric current is passed through an ionized gas in a magnetic field, and a chemical reaction occurs in the process of transferring energy from "heated" electrons to the molecules of the gas.

The temperature of the gas is in the range from +300 to +1000 ° C, while the reaction rate leading to the production of hydrogen is higher than in electrolysis. This method makes it possible to obtain hydrogen, which turns out to be twice (not three times) more expensive than traditional fuel obtained from hydrocarbons.

The plasma-chemical process takes place in two stages: first, carbon dioxide decomposes into oxygen and carbon monoxide, then carbon monoxide reacts with water vapor, which leads to hydrogen and the same carbon dioxide that was at the beginning (it is not consumed, if you look the entire loop transformation).

At the experimental stage — the plasma-chemical production of hydrogen from hydrogen sulfide, which remains a harmful product everywhere in the development of gas and oil fields. The rotating plasma simply ejects the sulfur molecules from the reaction zone by centrifugal forces, and the reverse reaction of conversion to hydrogen sulfide is excluded. This technology equalizes the price of hydrogen produced with traditional types of fossil fuels, in addition, sulfur is mined in parallel.

And Japan has already taken up the practical development of hydrogen energy today. Kawasaki Heavy Industries and Obayashi plan to start using hydrogen energy to power the city of Kobe by 2018. They will become pioneers among those who will actually start using hydrogen for large-scale electricity production, with virtually no harmful emissions.

A 1 MW hydrogen power plant will be built directly in Kobe, where it will supply electricity to an international convention center and work offices for 10,000 local residents. And the heat generated at the station in the process of generating electricity from hydrogen will become efficient heating for local houses and office buildings.

The gas turbines produced by Kawasaki Heavy Industries will, of course, not be supplied with pure hydrogen, but with a fuel mixture containing only 20% hydrogen and 80% natural gas.The plant will consume the equivalent of 20,000 hydrogen fuel cell vehicles per year, but this experience will be the start of major hydrogen power development in Japan and beyond.

Hydrogen reserves will be stored directly on the territory of the power plant, and even in the event of an earthquake or other natural disaster, there will be fuel in the station, the station will not be cut off from vital communications. By 2020, the port of Kobe will have infrastructure for major hydrogen imports as Kawasaki Heavy Industries plans to develop a large network of hydrogen power plants in Japan.