Automatic temperature control systems

According to the regulation principle, all automatic control systems are divided into four classes.

According to the regulation principle, all automatic control systems are divided into four classes.

1. Automatic stabilization system — a system in which the regulator maintains a constant set value of the controlled parameter.

2. Programmed control system — a system that provides a change in the controlled parameter according to a predetermined law (in time).

3. Tracking system — a system that provides a change in the controlled parameter depending on some other value.

4. Extreme regulation system — a system in which the regulator maintains the value of the controlled variable that is optimal for the changing conditions.

To regulate the temperature regime of electric heating installations, systems of the first two classes are mainly used.

Automatic temperature control systems by their type of operation can be divided into two groups: periodic and continuous regulation.

Automatic regulators automatic control systems (ACS) according to their functional features, they are divided into five types: positional (relay), proportional (static), integral (astatic), isodromic (proportional-integral), isodromic with advance and with the first derivative.

Positioners belong to periodic ACS, and other types of regulators are called continuous ACS. Below we consider the main characteristics of positional, proportional, integral and isodromic controllers, which are most often used in automatic temperature control systems.

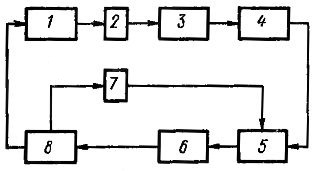

A functional diagram of automatic temperature control (Fig. 1) consists of a control object 1, a temperature sensor 2, a program device or temperature regulator 4, a regulator 5 and an actuator 8. In many cases, a primary amplifier 3 is placed between the sensor and the program device, and between the regulator and the drive mechanism — a secondary amplifier 6. An additional sensor 7 is used in isodromic control systems.

Rice. 1. Functional scheme of automatic temperature regulation

Thermocouples, thermocouples (thermistors) and resistance thermometers... The most commonly used thermocouples. For more details about them see here: Thermoelectric converters (thermocouples)

Positional (relay) temperature regulators

Positional refers to such regulators where the regulator can occupy two or three specific positions. Two- and three-position regulators are used in electric heating installations. They are simple and reliable to operate.

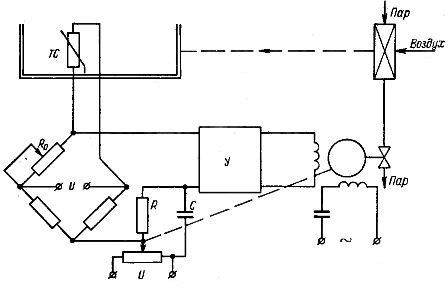

In fig. 2 shows a schematic diagram for controlling the air temperature on and off.

Rice. 2.Schematic diagram of air temperature regulation when switching on and off: 1 — control object, 2 — measuring bridge, 3 — polarized relay, 4 — excitation windings of the electric motor, 5 — motor armature, 6 — gearbox, 7 — heater .

To control the temperature in the object of regulation, the resistance RT is used, which is connected to one of the arms of the measuring bridge 2. The values of the resistances of the bridge are selected in such a way that at a given temperature the bridge is balanced, that is, the voltage in the diagonal of the bridge is equal to zero. When the temperature rises, the polarized relay 3, included in the diagonal of the measuring bridge, turns on one of the windings 4 of the DC motor, which, with the help of the reducer 6, closes the air valve in front of the heater 7. When the temperature drops, the air valve opens completely.

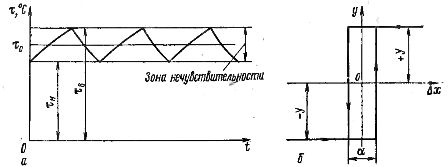

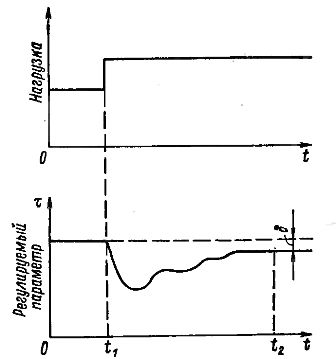

With two-position temperature regulation, the amount of supplied heat can be set to only two levels — maximum and minimum. The maximum amount of heat should be greater than necessary to maintain the set controlled temperature, and the minimum should be less. In this case, the air temperature fluctuates around the set value, that is, the so-called self-oscillating mode (Fig. 3, a).

Temperature lines τn and τв define the lower and upper limits of the dead zone. When the temperature of the controlled object, decreasing, reaches the value τThe amount of supplied heat instantly increases and the temperature of the object begins to rise. Reaching the sense τв, the regulator reduces the heat supply and the temperature decreases.

Rice. 3.Time characteristic of on-off regulation (a) and static characteristic for an on-off regulator (b).

The speed of temperature rise and fall depends on the properties of the controlled object and on its time characteristic (acceleration curve). Temperature fluctuations do not exceed the dead zone if changes in the heat supply immediately cause temperature changes, that is, if there is no lag of the controlled object.

As the dead zone decreases, the amplitude of temperature fluctuations decreases to zero at τn = τv. However, this requires the heat supply to vary at an infinitely high frequency, which is extremely difficult to implement in practice. There is a delay in all real control objects. The regulation process in them proceeds as follows.

When the temperature of the control object drops to the value τ, the power supply changes immediately, but due to the delay, the temperature continues to decrease for some time. Then it rises to the value τв, at which the heat input instantly decreases. The temperature continues to rise for some time, then due to the reduced heat input, the temperature drops and the process repeats again.

In fig. 3, b shows a static characteristic of a two-position controller... It follows that the regulating effect on the object can take only two values: maximum and minimum. In the considered example, the maximum corresponds to the position where the air valve (see Fig. 2) is fully open, the minimum — when the valve is closed.

The sign of the control action is determined by the sign of the deviation of the controlled value (temperature) from its set value. The degree of regulatory influence is constant. All on/off controllers have a hysteresis area α, which occurs due to the difference between the pick-up and drop-off currents of the electromagnetic relay.

Example of using two-point temperature control: Automatic temperature control in furnaces with heating resistance

Proportional (static) temperature controllers

In cases where high control accuracy is required or when the self-oscillating process is unacceptable, use regulators with a continuous regulation process... These include proportional controllers (P-controllers)suitable for regulating a wide variety of technological processes.

In cases where high regulation accuracy is required or when the self-oscillating process is unacceptable, regulators with a continuous regulation process are used. These include proportional controllers (P-controllers) suitable for regulating a wide variety of technological processes.

In automatic control systems with P-regulators, the position of the regulating body (y) is directly proportional to the value of the controlled parameter (x):

y = k1x,

where k1 is the proportionality factor (controller gain).

This proportionality takes place until the regulator reaches its end positions (limit switches).

The speed of movement of the regulating body is directly proportional to the speed of change of the controlled parameter.

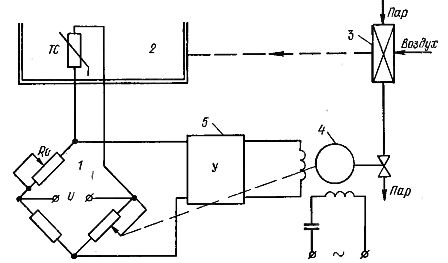

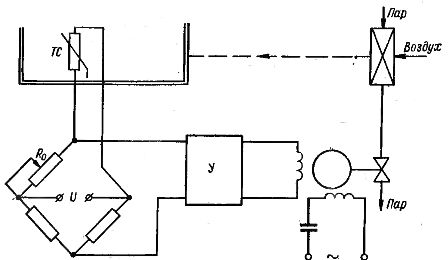

In fig.4 shows a schematic diagram of an automatic room temperature control system using a proportional controller. The room temperature is measured with an RTD resistance thermometer connected to the measurement circuit 1 of the bridge.

Rice. 4. Scheme of proportional air temperature control: 1 — measuring bridge, 2 — control object, 3 — heat exchanger, 4 — capacitor motor, 5 — phase-sensitive amplifier.

At a given temperature, the bridge is balanced. When the controlled temperature deviates from the set value, an unbalance voltage appears in the diagonal of the bridge, the magnitude and sign of which depend on the magnitude and sign of the temperature deviation. This voltage is amplified by a phase-sensitive amplifier 5, at the output of which the winding of a two-phase capacitor motor 4 of the drive is turned on.

The drive mechanism moves the regulating body, changing the flow of coolant in the heat exchanger 3. Simultaneously with the movement of the regulating body, the resistance of one of the arms of the measuring bridge changes, as a result of which the temperature at which the bridge is balanced.

Thus, due to the rigid feedback, each position of the regulating body corresponds to its own equilibrium value of the controlled temperature.

The proportional (static) controller is characterized by non-uniformity of the residual regulation.

In the case of a sharp deviation of the load from the set value (at the moment t1), the controlled parameter will reach after a certain period of time (moment t2) a new stable value (Fig. 4).However, this is possible only with a new position of the regulating body, that is, with a new value of the controlled parameter, which differs from the preset value by δ.

Rice. 5. Timing characteristics of proportional control

The disadvantage of proportional controllers is that only one specific control element position corresponds to each parameter value. To maintain the set value of the parameter (temperature) when the load (heat consumption) changes, it is necessary for the regulating body to take a different position corresponding to the new load value. In a proportional controller, this does not happen, resulting in a residual deviation of the controlled parameter.

Integral (astatic controllers)

Integral (astatic) are called such regulators in which, when the parameter deviates from the set value, the regulating body moves more or more slowly and all the time in one direction (within the working stroke) until the parameter again assumes the set value . The direction of movement of the adjusting element changes only when the parameter exceeds the set value.

In integral electrical action controllers, an artificial dead zone is usually created, within which a change in a parameter does not cause movements of the regulating body.

The speed of movement of the regulating body in the integral controller can be constant and variable. A characteristic feature of the integral controller is the absence of a proportional relationship between the steady-state values of the controlled parameter and the position of the regulating body.

In fig.6 shows a schematic diagram of an automatic temperature control system using an integral controller. Unlike the proportional temperature control circuit (see Fig. 4), it does not have a rigid feedback loop.

Rice. 6. Scheme of integrated air temperature control

In an integral controller, the speed of the regulating body is directly proportional to the value of the deviation of the controlled parameter.

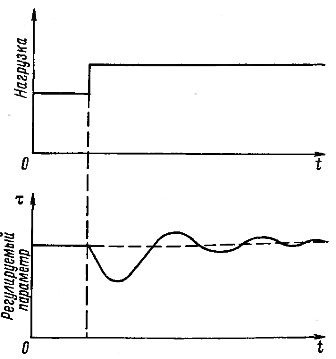

The process of integrated temperature control with a sudden change in load (heat consumption) is shown in Fig. 7 using temporal characteristics. As you can see from the graph, the controlled parameter with integral control slowly returns to the set value.

Rice. 7. Time characteristics of integral regulation

Isodromic (proportional-integral) controllers

Esodromic control has the properties of both proportional and integral control. The speed of movement of the regulating body depends on the magnitude and speed of deviation of the controlled parameter.

When the controlled parameter deviates from the set value, the adjustment is made as follows. Initially, the regulating body moves depending on the magnitude of the deviation of the controlled parameter, that is, proportional control is carried out. Then the regulator makes an additional movement, which is necessary to remove the residual irregularities (integral regulation).

An isodromic air temperature control system (Fig. 8) can be obtained by replacing the rigid feedback in the proportional control circuit (see Fig.5) with elastic feedback (from the regulating body to the motor for feedback resistance). Electrical feedback in an isodromic system is provided by a potentiometer and is fed into the control system through a loop containing resistance R and capacitance C.

During transients, the feedback signal together with the parameter deviation signal affects the subsequent elements of the system (amplifier, electric motor). With a stationary regulating body, in whatever position it is, when the capacitor C is charged, the feedback signal decays (in the stationary state it is equal to zero).

Rice. 8. Scheme of isodromic regulation of air temperature

It is characteristic of isodromic regulation that the non-uniformity of regulation (relative error) decreases with increasing time, approaching zero. In this case, the feedback will not cause residual deviations of the controlled value.

Thus, isodromic control produces significantly better results than proportional or integral (not to mention positional control). Proportional control due to the presence of rigid feedback occurs almost instantly, isodromic - more slowly.

Software systems for automatic temperature control

To implement programmed control, it is necessary to continuously influence the setting (setpoint) of the regulator so that the controlled value changes according to a predetermined law. For this purpose, the regulatory regulator is equipped with a software element. This device serves to establish the law of change of the set value.

During electric heating, the actuator of the automatic control system can act to turn on or off the sections of the electric heating elements, thereby changing the temperature of the heated installation in accordance with a given program. Programmed control of air temperature and humidity is widely used in artificial climate installations.