Automation of technological processes

Automation of production processes is the main direction in which manufacturing is currently moving around the world. Everything that was previously performed by man himself, his functions, not only physical, but also intellectual, are gradually passing to technology, which itself performs technological cycles and exercises control over them. This is the mainstream of modern technology now. The role of a human in many industries is now reduced to just a controller over an automatic controller.

Automation of production processes is the main direction in which manufacturing is currently moving around the world. Everything that was previously performed by man himself, his functions, not only physical, but also intellectual, are gradually passing to technology, which itself performs technological cycles and exercises control over them. This is the mainstream of modern technology now. The role of a human in many industries is now reduced to just a controller over an automatic controller.

In the general case, the term "process control" is understood as a set of operations necessary to start, stop the process, as well as to maintain or change in the required direction the physical quantities (process indicators). Individual machines, nodes, devices, devices, complexes of machines and devices that need to be controlled, which carry out technological processes, are called control objects or controlled objects in automation. Managed objects are very diverse in purpose.

Automation of technological processes — replacement of the physical labor of a person spent on the management of mechanisms and machines through the operation of special devices that provide this control (regulation of various parameters, achieving a certain productivity and quality of the product without human intervention).

The automation of production processes makes it possible to increase labor productivity several times, improve its safety, environmental friendliness, improve the quality of products and more effectively use production resources, including human potential.

Automation of technological processes and production does not mean that these processes are possible without human labor. Human labor today remains the basis of production, only its nature and content are changing. The functions of designing automatic devices, their periodic adjustment, development and introduction of programs fall to a person, which requires highly qualified specialists and, in general, the work of people becomes more complicated.

Every technological process is created and implemented with a specific purpose. Production of the final product or to obtain an intermediate result. So the purpose of automated production can be to sort, transport, pack the product. Production automation can be complete, complex and partial.

Partial automation occurs when an operation or a separate production cycle is carried out in automatic mode. In this case, limited participation of a person in it is allowed.Most often, partial automation takes place when the process proceeds too quickly for the person himself to fully participate in it, while quite primitive mechanical devices driven by electrical equipment do an excellent job with it.

Partial automation, as a rule, is used on already working equipment, it is an addition to it. However, it shows the greatest effectiveness when it is included in the overall automation system from the beginning — it is immediately developed, manufactured and installed as an integral part.

Complex automation should cover a separate large production area, it can be a separate workshop, power plant. In this case, the entire production works in the mode of a single interconnected automated complex. Full automation of production processes is not always advisable. Its field of application is modern highly developed production that uses extremely reliable equipment.

The failure of one of the machines or units immediately stops the entire production cycle. Such production must have self-regulation and self-organization, which is carried out according to a previously created program. At the same time, a person participates in the production process only as a permanent controller, monitors the state of the entire system and its individual parts, intervenes in the start-up and start-up production and in case of emergency situations, or with the threat of such an occurrence.

The highest level of automation of production processes — full automation... In it, the system itself exercises not only the production process, but also full control over it, which is carried out by automatic control systems.Full automation makes sense in cost-effective, sustainable production with established technological processes with a constant mode of operation.

All possible deviations from the norm must be foreseen in advance and systems for protection against them must be developed. Also, full automation is needed for work that can endanger human life, health or is carried out in places inaccessible to him - under water, in an aggressive environment, in space.

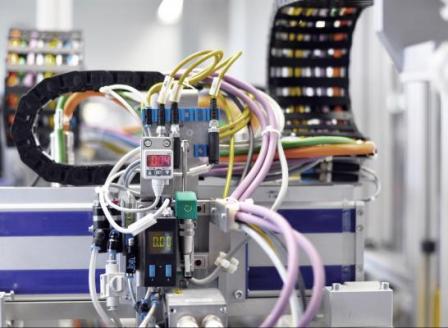

Each system consists of components that perform specific functions. In an automated system, sensors take readings and transmit them to make a decision on how to operate the system, the command is already executed by the device. Most often, this is electrical equipment, since with the help of electric current it is more expedient to execute commands.

It is necessary to separate the automated control system and the automatic. In an automated control system, sensors transmit readings to the operator's control panel, and he, having made a decision, transmits the command to the executive equipment. In an automatic system — the signal is analyzed by electronic devices, they, having made a decision, give a command to the executing devices.

Human involvement in automatic systems is necessary, albeit as a controller. He has the ability at any time to intervene in the technological process, to correct or stop it.

So the temperature sensor can get damaged and give incorrect readings. In this case, the electronics will perceive its data as reliable without questioning it.

The human mind many times surpasses the capabilities of electronic devices, although it is inferior to them in terms of reaction speed. The operator can recognize that the sensor is faulty, assess the risks and simply turn it off without interrupting the process. At the same time, he must be absolutely sure that this will not lead to an accident. Experience and intuition, which are unavailable to machines, help him make a decision.

Such targeted intervention in automatic systems does not pose a serious risk if the decision is made by a professional. Turning off all automation and transferring the system to manual control mode is fraught with serious consequences due to the fact that a person cannot quickly react to a change in the situation.

A classic example is the accident at the nuclear power plant in Chernobyl, which became the biggest man-made disaster of the last century. This happened precisely because of the shutdown of the automatic mode, when already developed emergency prevention programs could not influence the development of the situation in the station's reactor.

The automation of individual processes began in industry as early as the 19th century. Suffice it to recall the automatic centrifugal regulator for steam engines designed by Watt. But only with the beginning of the industrial use of electricity, a wider automation became possible not of individual processes, but of entire technological cycles. This is due to the fact that previously mechanical power was transmitted to metal cutting machines with the help of transmissions and drives.

Centralized production of electricity and its use in industry as a whole began only in the twentieth century - before the First World War, when every machine was equipped with its own electric motor. It was this circumstance that made it possible to mechanize not only the production process of the machine itself, but also to mechanize its management. This was the first step towards the creation of automatic machines... The first samples of which appeared in the early 1930s. Then the very term "automated production" arose.

In Russia, then in the USSR, the first steps in this direction were made in the 1930s and 1940s. For the first time, automatic metal cutting machines are used in the production of bearing parts. Then came the world's first fully automated production of pistons for tractor engines.

Technological cycles were combined into one automated process, starting with the loading of raw materials and ending with the packaging of finished parts. This became possible thanks to the widespread use of modern electrical equipment at that time, various relays, remote switches and, of course, drives.

And only the advent of the first electronic computers made it possible to reach a new level of automation. Now the technological process has ceased to be considered only as a set of separate operations that must be performed in a certain sequence in order to obtain a result. Now the whole process has become one.

Currently, automatic control systems not only conduct the production process, but also control it, monitor the occurrence of emergency and emergency situations.They start and stop technological equipment, monitor overloads and practice actions in case of accidents.

Recently, automatic control systems make it easier to rebuild equipment to produce new products. This is already a whole system consisting of individual automatic multimode systems connected to a central computer that connects them in a single network and issues tasks for execution.

Each subsystem is a separate computer with its own software designed to perform its own tasks. This is already flexible production modules. They are called flexible because they can be reconfigured to other technological processes and thus expand production, diversify it.

The pinnacle of automated manufacturing is industrial robots… Automation has permeated manufacturing from the top down. A transport line for the supply of raw materials for production works automatically. Management and design are automated. Human experience and intelligence are used only where electronics cannot replace them.