Power supplies for industrial automation devices

A wide class of devices for industrial automation is very different from ordinary household appliances, and accordingly the quality requirements for such devices are much higher. Energy facilities, industrial buildings, vehicles and transport equipment in general — in all these areas today there is automation of processes realized through the use of devices with special durability, reliability and increased safety.

The oil, gas, energy industries — require a reliable and safe power supply. Such devices must be resistant to vibration, have a wide temperature range, and sometimes be resistant to radiation.

Of course, the power supplies of these industrial automation devices always meet the requirements of a particular device as a whole, because the power supply is part of that device. If the power supply is below the requirements, the entire device becomes vulnerable.

Power supplies in industry are traditionally mounted in cabinets on DIN rails and therefore power supply enclosures are designed for this type of mounting. Some manufacturers produce special adapter kits for mounting power supplies on a DIN rail.

Of course, power supplies for industrial automation have specific characteristics, and depending on the tasks that are solved using a specific power supply, they can all be divided into several types: isolated AC / DC converters, backup modules, UPS power supplies support isolated DC / DC converters. All these types of power supplies have one thing in common — their parameters are stable under various external conditions.

The various electronic components of industrial installations require their own operating voltage, that is, not all components have the same supply voltage. For this reason, manufacturers of power supplies for industrial automation make sure that there are several channels of different voltages, including bipolar, on one device. There are also controlled power supplies that are turned on or off by a signal from external industrial sensors driving a logic level to a dedicated input.

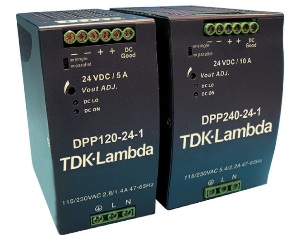

The three leading manufacturers of power supplies for the industry — MW, Chinfa and TDK-Lambda — almost completely cover the needs of modern industrial automation devices with their assortment. At the same time, the power supplies of these brands meet both reliability and safety requirements and electromagnetic compatibility requirements.

Isolated AC / DC converters

Power supplies of this type are traditionally used as basic stabilized power supplies.They receive power from the mains (three-phase or single-phase) or from a direct current source, while the supply voltage range is quite wide - from 120 to 370 volts DC.

This type of power supply is the most common in electrical circuits for industrial automation, since the power supply is present almost everywhere.

In addition, the range of characteristics is very wide — output voltage, maximum current, design — all these parameters vary, and manufacturers on their websites provide the user with a choice.

Particularly noteworthy are the power supplies with a lifetime warranty (for example, the HWS series from TDK-Lambda), with the ability to compensate for the voltage drop on the wires, with output voltage regulation and with the ability to turn off / on remotely.

Some series of isolated AC / DC converters have the ability to withstand a double overload with rated power for a few seconds (for example, the ZWS / BP series from TDK-Lambda), which is very important for powering motors, when in overload mode, the motors consume significant power for a few seconds, but in the main mode the consumption is half as much. There is an opportunity to save money on the purchase of a powerful converter.

Chinfa and MW mainly supply converters specifically for DIN rail mounting. Chinfa power supplies traditionally have outputs for 15 and 5 volts and can work even at freezing temperatures down to -40 ° C. All power supplies from these manufacturers can be powered from 85 to 264 volts. For automation systems with increased power, three-phase versions of power supplies are also provided.

Most power supplies for industrial applications have in their design active PFC power factor correction and the ability to adjust the output voltage within + -15% of nominal.

Sometimes it is necessary to connect several power supplies in parallel to supply the load with a power higher than the nominal value of one power supply; for this purpose, some models of isolated AC / DC converters are equipped with a special switch that allows you to adjust the feedback circuits of several sources, with one of the blocks being the master, and the others are put in slave mode. This scheme differs from the scheme used for the redundancy problem, the solution of which will be discussed below.

Spare modules

Such devices are designed to improve system reliability when there is a risk of failure of one of the converters. Several power supplies are connected to one common bus with diode isolation, and in case of failure of one source, the second is connected immediately. Outwardly, it looks like connecting isolation diodes to backup power supplies.

Spare modules ensure continuous operation of the equipment for a long time without disrupting the technological cycle — this is their main task. The decoupling diodes start to be done strictly when needed, which is why there is a difference between the diodes built into the power supply and the diodes put into the backup module.

In the second case, the efficiency of the power supplies increases. If one of the power supplies fails, a hot swap occurs and the system continues to operate.The operator will have to track the failure of the device (according to the voltage monitoring scheme at the output of an individual unit) and ensure its timely replacement or service.

Most often, for the purpose of industrial automation, a voltage of 24 volts is used, and spare modules are manufactured mainly for this nominal voltage. If the voltage is 12 volts, then the module will not be able to control the voltage at its input, and then you have to resort to choosing power supplies with a built-in control system.

Power supplies with UPS support

These are power supplies with the function of monitoring the condition of the batteries and with the function of charging them. UPS power supplies are connected in parallel with the main power source and maintain the correct voltage level in the event of a power outage or in the event of a failure of this main power source. Backup battery charging is supported at the same time. Such applications are in high demand in industrial automation with backup sources, especially batteries.

The controller of the device (similar to those produced by Chinfa and Mean Well) always maintains the battery charge at the correct level, does not allow discharge and does not lead to recharging. That is, the power supply combines the function of a UPS (uninterruptible power supply).

Each product offered by manufacturers is designed for batteries of a certain capacity, in accordance with the rating, and can have two output voltages: 24 and 12 volts. More expensive controllers have an adjustable battery charging current, cheaper ones have a constant level of charging current, for example 2 amps.

Isolated DC / DC converters

Isolated DC / DC converters (converters) are designed to change the DC voltage level… They are installed inside cabinets or function modules, because sometimes industrial automation systems require different DC voltages for different equipment.

So, for example, if you already have an isolated AC / DC converter, but you also need to get another voltage, other than what is already provided by the device already installed in the cabinet, you can cope with a DC / DC converter, it will be more -cheaper than buying another one. AC/DC.

Isolated DC / DC converters for mounting on a DIN rail are produced by TDK -Lambda, which represents a range of converters with a different number of output channels for power from 15 to 60 W. The devices have protection against reverse polarity and a circuit for limiting the inrush current, as well as traditional short circuit protection. The LED indicator indicates the presence of nominal voltage at the channel outputs. It is possible to turn it off and on remotely.

So the modern market of power supplies for industrial automation is full of devices with any parameters that may be needed. The range will allow you to choose any voltage, power, form factor, remote control options, UPS function, etc.

Power over 1500 watts can be obtained by combining several blocks in parallel. Spare modules will help to establish trouble-free operation of circuits. UPS devices will not interrupt the process. DC -DC — the converter will provide the required DC voltage.