Smart sensors and their use

According to GOST R 8.673-2009 GSI "Intelligent sensors and intelligent measuring systems. Basic terms and definitions ”, intelligent sensors are adaptive sensors containing work algorithms and parameters changing from external signals, and in which the function of metrological self-control is also implemented.

A distinctive feature of smart sensors is the ability to self-heal and self-learn after a single failure. In the English-language literature, sensors of this type are called "smart sensor". The term stuck in the mid-1980s.

Today, a smart sensor is a sensor with embedded electronics, including: ADC, microprocessor, digital signal processor, system-on-chip, etc., and a digital interface with support for network communication protocols. In this way, the smart sensor can be included in a wireless or wired sensor network, thanks to the self-identification function in the network together with other devices.

The network interface of a smart sensor allows you not only to connect it to the network, but also to configure it, configure it, select an operating mode and diagnose the sensor. The ability to perform these operations remotely is an advantage of smart sensors, they are easier to operate and maintain.

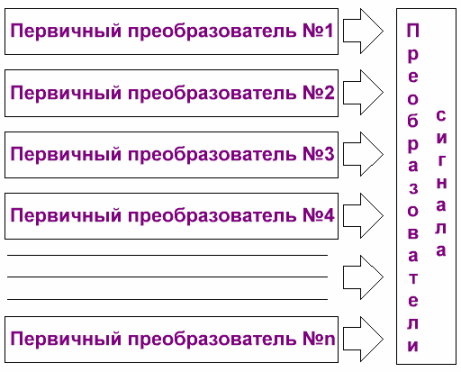

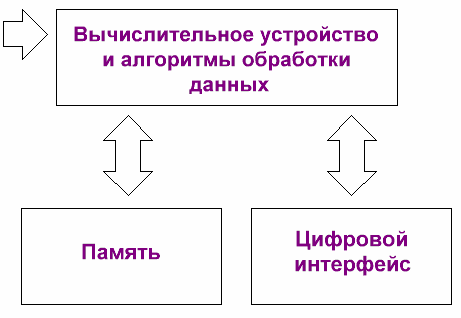

The figure shows a block diagram showing the basic blocks of a smart sensor, the minimum necessary for the sensor to be considered as such. The incoming analog signal (one or more) is amplified, then converted to a digital signal for further processing.

The ROM contains calibration data, the microprocessor correlates the received data with the calibration data, corrects it and converts it to the necessary units of measurement - thus the error associated with the influence of various factors (zero drift, temperature influence, etc.) is compensated and the condition is evaluated simultaneously with the primary transducer, which may affect the reliability of the result.

Information obtained as a result of processing is transmitted through a digital communication interface using the user's protocol. The user can set the measurement limits and other parameters of the sensor, as well as get information about the current state of the sensor and the results of the measurements.

Modern integrated circuits (systems on a chip) include, in addition to a microprocessor, memory and peripherals such as precision digital-to-analog and analog-to-digital converters, timers, Ethernet, USB and serial controllers. Examples of such integrated circuits include ADuC8xx from Analog Devices, AT91RM9200 from Atmel, MSC12xx from Texas Instruments.

Distributed networks of intelligent sensors enable real-time monitoring and control of parameters of complex industrial equipment, where technological processes dynamically change their state all the time.

There is no single network standard for smart sensors and this is a kind of obstacle for the active development of wireless and wired sensor networks. Nevertheless, many interfaces are used today: RS-485, 4-20 mA, HART, IEEE-488, USB; industrial networks work: ProfiBus, CANbus, Fieldbus, LIN, DeviceNet, Modbus, Interbus.

This state of affairs raised the question of the choice of sensor manufacturers, since it is not economically viable for each network protocol to produce a separate sensor with the same modification. Meanwhile, the emergence of the IEEE 1451 group of standards "Intelligent Transducer Interface Standards" eased the conditions, the interface between the sensor and the network is unified. The standards are designed to accelerate adaptation — from individual sensors to sensor networks, several subgroups define software and hardware methods for connecting sensors to a network.

Thus, two classes of devices are described in the IEEE 1451.1 and IEEE 1451.2 standards. The first standard defines a unified interface for connecting smart sensors to the network; this is the specification of the NCAP module, which is a kind of bridge between the STIM module of the sensor itself and the external network.

The second standard specifies a digital interface for connecting a STIM smart converter module to a network adapter. The TEDS concept implies an electronic passport of the sensor, for the possibility of its self-identification in the network.TEDS includes: date of manufacture, model code, serial number, calibration data, date of calibration, units of measurement. The result is a plug and play analog for sensors and networks, easy operation and replacement guaranteed. Many smart sensor manufacturers already support these standards.

The main thing that the integration of sensors in a network gives is the possibility of accessing measurement information through software, regardless of the type of sensor and how a particular network is organized. It turns out to be a network that serves as a bridge between the sensors and the user (computer), helping to solve technological problems.

Thus, a smart metering system can be represented by three levels: sensor level, network level, software level. The first level is the level of the sensor itself, a sensor with a communication protocol. The second level is the sensor network level, the bridge between the sensor object and the problem solving process.

The third level is the software level, which already implies the interaction of the system with the user. The software here can be completely different as it is no longer tied directly to the digital interface of the sensors. Sub-levels related to subsystems are also possible in the system.

In recent years, the development of smart sensors has taken several directions.

1. New measurement methods requiring powerful computing inside the sensor. This will enable sensors to be located outside the measured environment, thereby increasing the stability of readings and reducing operational losses. The sensors have no moving parts, which improves reliability and simplifies maintenance.The design of the measuring object does not affect the operation of the sensor and the installation becomes cheaper.

2. Wireless sensors are undeniably promising. Moving objects distributed in space require wireless communication with the means of their automation, with controllers. Radio technical devices are becoming cheaper, their quality is increasing, wireless communication is often more economical than cable. Each sensor can transmit information on its own time slot (TDMA), on its own frequency (FDMA) or with its own coding (CDMA), finally Bluetooth.

3. Miniature sensors can be embedded in industrial equipment, and automation equipment will become an integral part of the equipment that performs the technological process, not an external addition. A sensor with a volume of several cubic millimeters will measure temperature, pressure, humidity, etc., process the data and transmit the information over the network. The accuracy and quality of instruments will increase.

4. The advantage of multi-sensor sensors is obvious. A common converter will compare and process data from several sensors, that is, not several separate sensors, but one, but multifunctional.

5. Finally, the intelligence of sensors will increase. Value prediction, powerful data processing and analysis, full self-diagnosis, fault prediction, maintenance advice, logic control and regulation.

Over time, smart sensors will become more and more multifunctional automation tools, for which even the term "sensor" itself will become incomplete and merely conditional.