The use of a PID controller in automation systems on the example of the TRM148 OWEN

Automatic adjustment, adjustment system

Automatic control is a type of automatic control. Maintaining the constancy of a certain value characterizing the technological process, or its change according to a given law, carried out by measuring the state of a controlled object or disturbances by affecting the regulatory body of the object.

To perform automatic regulation, a set of devices is connected to the installation to be regulated, the combination of which is called a regulator.

Based on measurements of one or more variables characterizing the process, the controller affects the process by changing one or more control actions, maintaining the set value of the controlled variable.

A control system — a system designed to maintain a given law of change of a certain physical quantity is called a controlled quantity.The setpoint of the controlled variable may be constant, or it may be a function of time or some other variable.

In the regulation process, the controlled value is compared with the set value, and in the presence of a deviation of the controlled value from the set value, the regulating action enters the control object, restoring the controlled value.

Regulatory action can be entered manually by a person. If the measurement of the controlled variable and the introduction of the control action are done by instruments, without human intervention, then the control system is called an autonomous system.

In addition to the control action, control systems are affected by disturbances that cause the controlled variable to deviate from the set value and the occurrence of control errors.

By the nature of the change in the control action, control systems are subdivided into automatic stabilization systems (the control action is a constant value or is a given function of the time of the programmed control system) and servo systems (the change in the control action is determined by a previously unknown control action) ).

PID controllers

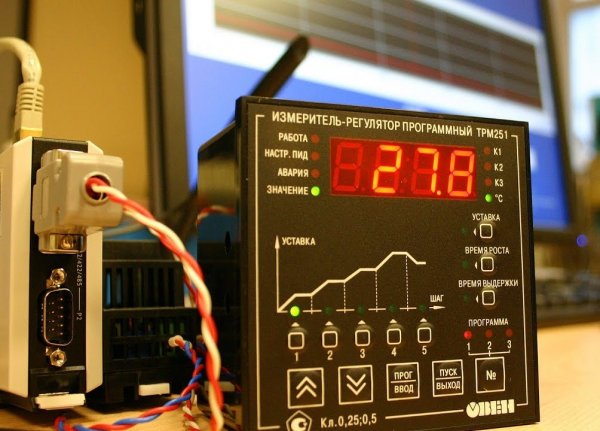

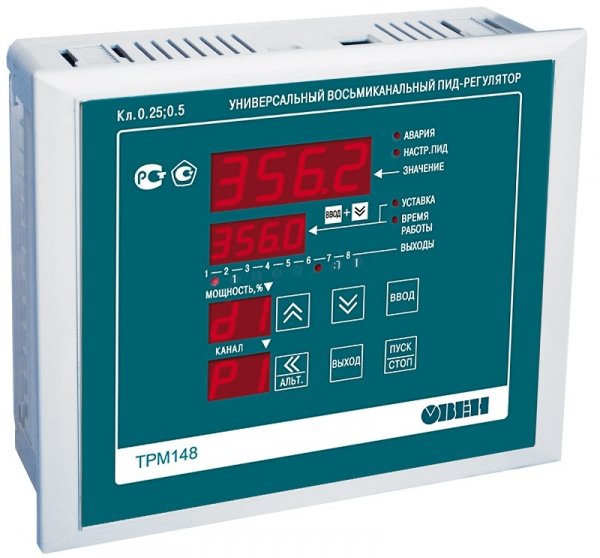

The PID controller is a ready-made device that will allow the user to implement a software algorithm to control one or another piece of equipment of an automated system. Building and configuring regulation (control) systems becomes much easier if you use ready-made devices such as the universal PID controller TRM148 for 8 channels from the OWEN company.

Let's say you need to automate the maintenance of the right climatic conditions in the greenhouse: take into account the temperature of the soil near the roots of the plants, the air pressure, the humidity of the air and the soil, and maintain the specified parameters through control Heating element and fans. It couldn't be easier, just tune the PID controller.

Let's first recall what is a PID controller? The PID controller is a special device that continuously refines the output parameters in three ways: proportional, integral and differential, and the initial parameters are input parameters obtained from sensors (pressure, humidity, temperature, illumination, etc.).

The input parameter is fed to the input of the PID controller from a sensor, for example a humidity sensor. The regulator receives the value of the voltage or current, measures it, then makes calculations according to its algorithm and finally sends a signal to the corresponding output, as a result of which the automated system receives a control action. Soil moisture decreased - watering was turned on for a few seconds.

The goal is to achieve a user-defined humidity value. Or for example: lighting has decreased - turn on phytolamps on plants, etc.

PID control

In fact, although everything looks simple, the math inside the regulator is more complicated, not everything happens in one step. After irrigation is turned on, the PID controller measures again, measuring how much the input value has now changed—this is the control error.The next action on the drive will now be corrected, taking into account the measured adjustment error, and so on at each control step until the target — a user-defined parameter — is reached.

Three components are involved in regulation: proportional, integral and differential. Each component has its own degree of importance in each particular system, and the greater the contribution of this or that component, the more essential it is to be changed in the regulation process.

The proportional component is the simplest, the greater the change, the greater the coefficient (of proportionality in the formula), and to reduce the impact, it is enough to simply reduce the coefficient (multiplier).

Let's say that the soil moisture in the greenhouse is much lower than the set point - then the watering time should be as long as the current moisture is lower than the set point. This is a crude example, but the principle is roughly the same.

Integral component — it is necessary to improve the accuracy of control based on previous control events: previous errors are integrated and a correction is made on them to ultimately obtain zero deviation in future control.

And finally, the differential component. Here the rate of change of the controlled variable is considered. Regardless of whether the setpoint is changed smoothly or suddenly, the control action must not lead to excessive deviations in the value during the control.

It remains to choose a device for PID control. Today there are many of them on the market, there are multi-channel ones that allow you to change several parameters at once, as in the above example with a greenhouse.

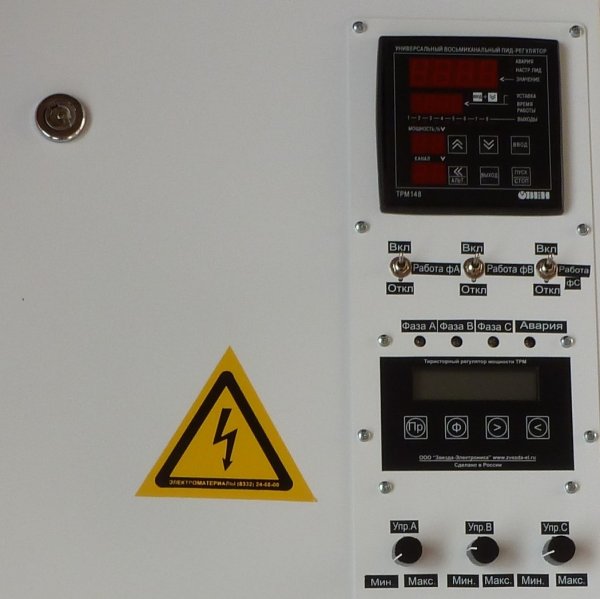

Let's look at the device of the regulator using the example of the universal PID regulator TRM148 from the OWEN company.

The eight input sensors feed signals to the respective inputs. Signals are scaled, filtered, corrected, their values can be seen on the display by switching with buttons.

The outputs of the device are produced in various modifications in the necessary combinations of the following:

-

relay 4 A 220 V;

-

transistor optocouplers n-p-n-type 400 mA 60 V;

-

triac optocouplers 50 mA 300 V;

-

DAC «parameter — current 4 … 20 mA»;

-

DAC «parameter-voltage 0 … 10 V»;

-

4 … 6 V 100 mA solid state relay control output.

So, the control action can be analog or digital. Digital signal — these are pulses of variable width, and analog — in the form of continuous alternating voltage or current in a uniform range: from 0 to 10 V for voltage and from 4 to 20 mA — for current signal.

These output signals are only used to control actuators, say an irrigation system pump or a relay that turns a heating element on and off or a motor to control an actuator valve. There are signal indicators on the control panel.

For interaction with a computer, the TPM148 regulator is equipped with an RS-485 interface that allows:

For interaction with a computer, the TPM148 regulator is equipped with an RS-485 interface that allows:

-

configure the device on a computer (configuration software is provided free of charge);

-

transmit to the network the current values of the measured values, the output power of the regulator, as well as all programmable parameters;

- receive operational data from the network to generate control signals.