Classification of electromechanical energy converters

It is customary to use two main classification features:

a) by appointment.

1) generators — designed to convert mechanical energy into electrical energy. Sources of mechanical energy — steam and hydraulic turbines, internal combustion engines, industrial frequency electric motors, etc.

2) engines — are designed to convert electrical energy into mechanical energy, i.e. for rotating actuators (working machines).

3) electrical machine converters: the type of current (DC to AC and vice versa), the number of phases of the current (1 to 3 and vice versa), the frequency of the current, etc. They are now being superseded by electronic transducers in general industrial applications.

4) electric machine power amplifiers (EMUs) (replaced by electronic power amplifiers).

5) signal converters. These are micromachines (up to 600 W) used as elements of control systems, measuring and computing devices.

6) power micromotors — operation in "on-off" mode for constant load, used for example to drive recorders, tape drives, computer devices, etc.

7) executive engines (in English literature — servomotors) — convert electrical power (control signal) into rotational speed or angle of rotation of the shaft.

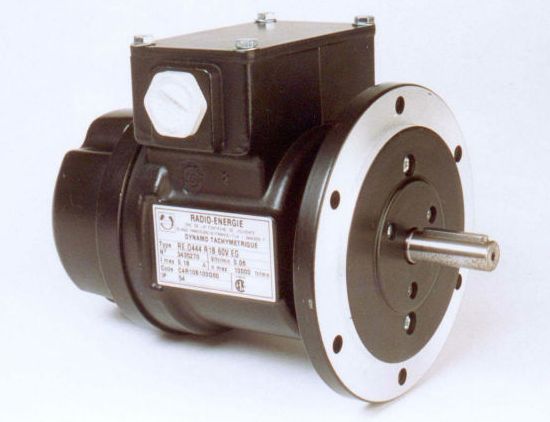

8) tachogenerators — converters (sensors) with mechanical value — rotation speed — in electrical (voltage).

9) rotating (rotary) transformers (VT, SKVT, SKPT) — elements of analog computers, converters of mechanical quantities into electrical signals, shaft position sensors.

9) rotating (rotary) transformers (VT, SKVT, SKPT) — elements of analog computers, converters of mechanical quantities into electrical signals, shaft position sensors.

10) synchronous communication machines (selsyns) — sensors of automatic control systems that perform synchronous and in-phase rotation or rotation of two or more mechanically unrelated axes (sometimes used as power machines, the energy of which participates in the movement of actuators).

11) micromachines gyroscopic devices — specific requirements are imposed on them — high rotation speeds and high accuracy in determining angles and moments.

b) by the nature of the current and the principle of operation

1) direct current.

Such electromechanical energy converters are used as generators and motors in electric drives that require a change in the speed of rotation in a wide range (automatic control systems, railway and other types of electrified transport, roller mills, complex metal-cutting machines, etc.). They are also widely used in autonomous objects where the on-board network is powered by accumulators or batteries (aviation, space, fleet, cars...).

2) alternating current.

-

transformers (static machines, excluding so-called rotary transformers) designed to convert the magnitude of alternating current voltage;

-

asynchronous machines: usually used as motors operating at a constant speed of rotation - metal cutting machines, household appliances, ... In ACS - executive motors, tachogenerators, selsins;

-

synchronous machines — more often industrial frequency alternators in power plants, as well as increased frequency in autonomous power supplies. In ACS — synchronous motors with low power (reactive, induction, stepper, etc.);

-

collector — used mainly as a universal — both direct and alternating current.