What is mechatronics, mechatronic elements, modules, machines and systems

The word "mechatronics" is formed from two words - "mechanics" and "electronics". This term was proposed in 1969 by a senior developer at Yaskawa Electric, a Japanese named Tetsuro Mori. In the 20th century, Yaskawa Electric specialized in the development and improvement of electric drives and DC motors and therefore achieved great success in this direction, for example, the first disc armature DC motor was developed there.

This was followed by developments regarding the first hardware CNC systems. And in 1972, the Mechatronics brand was registered here. The company soon made great strides in the development of electric drive technologies. The company later decided to drop the word "Mechatronics" as a trademark, as the term was widely used both in Japan and around the world.

In any case, Japan is home to the most active development of such an approach in technology, when it became necessary to combine mechanical elements, electrical machines, power electronics, microprocessors and software to implement high-precision electric drive control.

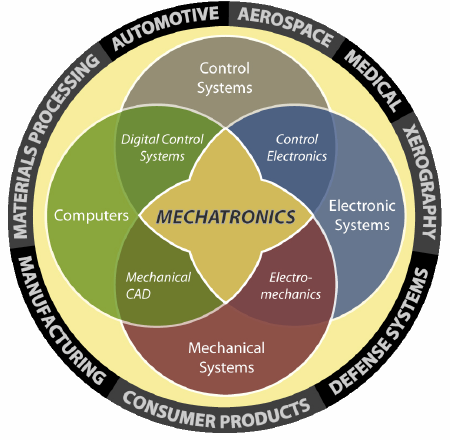

A common graphic symbol for mechatronics is a diagram from the RPI (Rensselaer Polytechnic Institute, NY, USA) website:

Mechatronics is one of the newest engineering fields in the world, which, according to UNESCO, is one of the ten most promising and sought after.

Generally speaking, the term "mechatronics" can be given the following definition — it is a field of science and technology based on a systematic combination of units for precision mechanics, electrical engineering, electronics, microprocessor technology, various power sources, electrical, hydraulic and pneumatic drives, as well as their intelligent control, focused on the creation and operation of blocks of modern automated production systems.

Mechatronics is computerized motion control.

The goal of mechatronics is to create qualitatively new motion modules, mechatronic motion modules, intelligent mechatronic modules and, on their basis, moving intelligent machines and systems.

Historically, mechatronics evolved from electromechanics and, relying on its achievements, went further by systematically combining electromechanical systems with computer control devices, embedded sensors and interfaces.

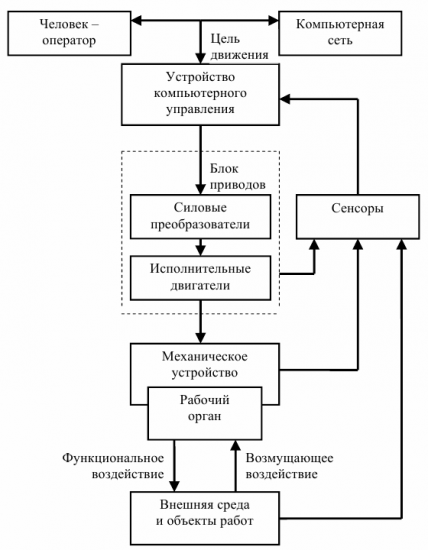

Diagram of the mechatronic system

Generalized structure of mechatronic systems

Electronic, digital, mechanical, electrical, hydraulic, pneumatic and information elements — can be part of the mechatronic system, as initially elements of a different physical nature, however, brought together to obtain a qualitatively new result of the system, which cannot be achieved by each element as by a separate performer.

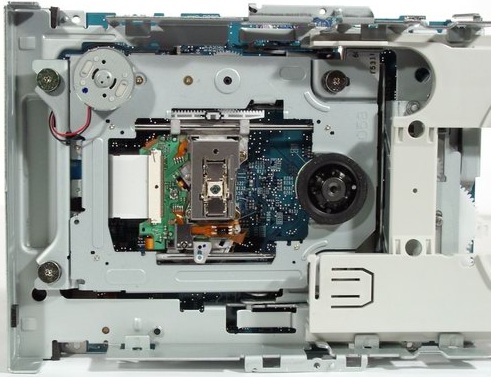

A separate spindle motor will not be able to eject the DVD player tray by itself, but under the control of a circuit with microcontroller software and properly connected to a worm gear, everything will work out easily and look like a simple monolithic system. However, despite the external simplicity, a mechatronic system by definition includes several mechatronic units and modules interconnected and interacting together to perform specific functional actions to solve a specific task.

A mechatronic module is an independent product (structurally and functionally) designed to perform movements with interpenetration and simultaneous purposeful hardware and software integration of its components.

A typical mechatronic system consists of interconnected electromechanical and power components that are in turn controlled by a computer or microcontrollers.

When designing and building such a mechatronic system, they try to avoid unnecessary nodes and interfaces, try to make everything concise and as seamless as possible, not only in order to improve the mass-size characteristics of the device, but also to increase the reliability of the system generally.

Sometimes it is not easy for engineers, they are forced to find very unusual solutions precisely due to the fact that different units are in different working conditions, doing completely different things. For example, in some places a conventional bearing will not work, and it is replaced by an electromagnetic suspension (this is done, in particular, in turbines pumping gas through pipes, since a conventional bearing would quickly fail due to the penetration of gas into its lubricant).

In one way or another, today mechatronics has permeated everything from household appliances to construction robotics, weapons and aerospace. All CNC machines, hard drives, electric locks, the ABS system in your car, etc. — everywhere, mechatronics is not only useful, but also necessary. It is now rare where you can find manual control, it all boils down to the fact that you pressed the button without fixation or simply touched the sensor — you got the result — this is perhaps the most primitive example of what mechatronics is today.

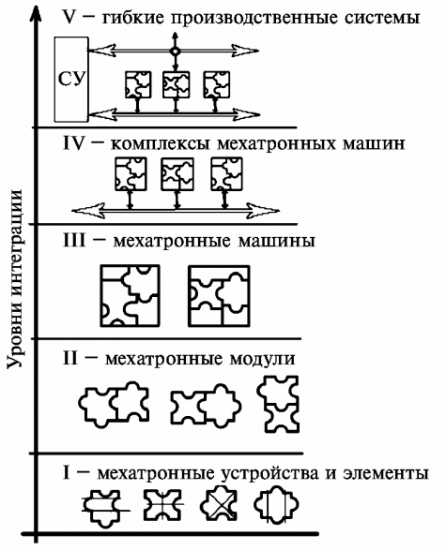

Hierarchy diagram of integration levels in mechatronics

The first level of integration is formed by mechatronic devices and their elements. The second level of integration is formed by the integrated mechatronic modules. The third level of integration is formed by the integration mechatronic machines. The fourth level of integration is formed by the complexes of mechatronic machines. The fifth level of integration is formed on a single integration platform of complexes of mechatronic machines and robots, which imply the formation of reconfigurable flexible production systems.

Today, mechatronic modules and systems are widely used in the following areas:

-

mechanical engineering and automation equipment, technological processes in mechanical engineering;

-

industrial and special robotics;

-

aviation and space technology;

-

military equipment, vehicles for the police and special services;

-

electronic engineering and rapid prototyping equipment;

-

automotive industry (motor wheel drive modules, anti-lock brakes, automatic transmissions, automatic parking systems);

-

non-traditional vehicles (electric cars, electric bicycles, wheelchairs);

-

office equipment (eg copiers and fax machines);

-

computer peripherals (eg printers, plotters, CD-ROM drives);

-

medical and sports equipment (bioelectric and exoskeleton prostheses for the disabled, toning trainers, controlled diagnostic capsules, massagers, etc.);

-

household appliances (washing, sewing, dishwashers, independent vacuum cleaners);

-

micromachines (for medicine, biotechnology, communications and telecommunications);

-

control and measuring devices and machines;

-

elevator and warehouse equipment, automatic doors in hotels and airports; photo and video equipment (videodisc players, video camera focusing devices);

-

simulators for training operators of complex technical systems and pilots;

-

railway transport (train control and stabilization systems);

-

intelligent machines for the food, meat and dairy industries;

-

printing machines;

-

smart devices for the show industry, attractions.

Accordingly, the need for personnel with mechatronic technologies is increasing.