Automation objects and their characteristics

Automation objects (control objects) — these are separate installations, metal-cutting machines, machines, aggregates, devices, complexes of machines and devices that must be controlled. They are very diverse in purpose, structure and principle of action.

The object of automation is the main component of the automatic system, which determines the nature of the system, therefore special attention is paid to its study. The complexity of an object is determined mainly by the degree of its knowledge and the variety of functions it performs. The results of the study of the object must be presented in the form of clear recommendations regarding the possibility of full or partial automation of the object or the absence of the necessary conditions for automation.

Characteristics of automation objects

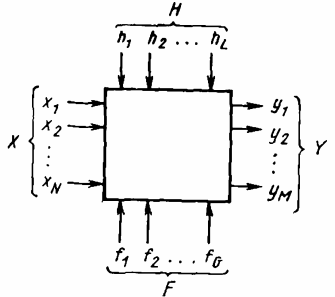

The design of an automatic control system must be preceded by a site survey to establish site relationships. In general, these relationships can be represented as four groups of variables.

A controlled disturbance, whose collection forms the L-dimensional vector H = h1, h2, h3, ..., hL... They include measurable variables that depend on the external environment, such as the quality indicators of raw materials in the foundry, the amount of steam consumed in the steam boiler, the water flow in the instantaneous water heater, the temperature of the air in the greenhouse, which varies depending on the external environmental conditions and the factors affecting the process. For controlled disturbances, limitations are placed on the technological conditions.

The indicator of the technological process to be controlled is called the controlled quantity (coordinate), and the physical quantity by which the indicator of the technological process is controlled is called the controlling action (input quantity, coordinate).

Control actions, the totality of which forms an n-dimensional vector X = x1, x2, x3, ..., xn... They are independent of the external environment and have the most significant impact on the technological process. With their help, the course of the process is purposefully changed.

To control actions include the switching on and off of electric motors, electric heaters, actuators, the position of control valves, the position of regulators, etc.

Output variables, the set of which forms the M-dimensional state vector Y = y1, y2, y3, ..., yМ... These variables are the output of the object, which characterizes its state and determines the quality indicators of the finished product.

Uncontrolled disturbing influences, whose collection forms the G-dimensional vector F = ε1, ε2, ε3, …, εG... They include such disturbances that cannot be measured for one reason or another, for example due to lack of sensors.

Rice. 1.Inputs and outputs of the automation object

Studying the considered relationships of the object to be automated can lead to two diametrically opposite conclusions: there is a strict mathematical dependence between the output and input variables of the object, or there is no dependence between these variables that can be expressed by a reliable mathematical formula.

In the theory and practice of automatic control of technological processes, sufficient experience has been gained in describing the state of an object in such situations. In this case, the object is considered one of the links in the automatic control system. In cases where the mathematical relationship between the output variable y and the control input action x of the object is known, two main forms of recording mathematical descriptions are distinguished — these are the static and dynamic characteristics of the object.

Static characteristic in mathematical or graphical form expresses the dependence of the output parameters on the input. Binary relationships usually have a clear mathematical description, for example, the static characteristic of weighing dispensers for casting materials has the form h = km (here h is the degree of deformation of the elastic elements; t is the mass of the material; k is the proportionality factor, which depends on the properties of the material of the elastic element).

If there are several variable parameters, nomograms can be used as static characteristics.

The static characteristic of the object determines the subsequent formation of automation targets. From the point of view of practical implementation in foundry, these objectives can be reduced to three types:

-

stabilization of the initial parameters of the object;

-

changing the output parameters according to a given program;

-

change in the quality of some output parameters when the process conditions change.

However, a number of technological objects cannot be described mathematically due to the multitude of interrelated factors affecting the course of the process, the presence of uncontrollable factors and the lack of knowledge about the process. Such objects are complex from the point of view of automation. The degree of complexity is determined by the number of inputs and outputs of the object. Such objective difficulties arise in the study of processes reduced by mass and heat transfer. Therefore, in their automation, assumptions or conditions are necessary, which should contribute to the main goal of automation — to increase the efficiency of management by maximally approaching the technological modes to the optimal ones.

To study complex objects, a technique is used, which consists in a conditional representation of an object in the form of a «black box». At the same time, only external connections are studied, nor is the morning structure of the system taken into account, that is, they study what the object does, not how it functions.

The behavior of the object is determined by the response of the output values to changes in the input values. The main tool for studying such an object is statistical and mathematical methods. Methodologically, the study of the object is carried out in the following way: the main parameters are determined, a discrete series of changes in the main parameters is established, the input parameters of the object are artificially changed within the established discrete series, all changes in the outputs are recorded and the results are processed statistically .

Dynamic characteristics an object of automation is determined by a number of its properties, some of which contribute to a high-quality control process, others hinder it.

Of all the properties of automation objects, regardless of their variety, the main, most characteristic ones can be distinguished: capacity, ability to self-align and lag.

Capacity is the ability of an object to accumulate the working environment and store it in the object. The accumulation of matter or energy is possible due to the fact that there is an output resistance in every object.

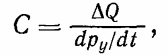

The measure of the capacity of the object is the coefficient of capacity C, which characterizes the amount of matter or energy that must be supplied to the object in order to change the controlled value by one unit in the accepted measurement size:

where dQ is the difference between the inflow and consumption of matter or energy; ru — controlled parameter; t is time.

The size of the capacity factor can be different depending on the sizes of the controlled parameters.

The rate of change of the controlled parameter is the smaller, the greater the capacity factor of the object. It follows that it is easier to control those objects whose capacity coefficients are larger.

Self-levelling This is the ability of an object to enter a new steady state after a disturbance without the intervention of a control device (regulator). Objects that have self-alignment are called static, and those that do not have this property are called neutral or astatic . Self-alignment contributes to the stabilization of the control parameter of the object and facilitates the operation of the control device.

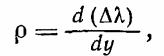

Self-leveling objects are characterized by a coefficient (degree) of self-leveling, which looks like this:

Depending on the self-leveling coefficient, the static characteristics of the object take a different form (Fig. 2).

Dependence of the controlled parameter on the load (relative disturbance) at different self-leveling coefficients: 1-ideal self-leveling; 2 — normal self-levelling; 3 — lack of self-leveling

Dependency 1 characterizes an object for which the controlled value does not change under any disturbances, such an object does not need control devices. Dependency 2 reflects the normal self-alignment of the object, dependency 3 characterizes an object that has no self-alignment. The coefficient p is variable, it increases with increasing load and in most cases has a positive value.

A delay — this is the time elapsed between the moment of unbalance and the beginning of the change in the controlled value of the object. This is due to the presence of resistance and the momentum of the system.

There are two types of delay: pure (or transport) and transient (or capacitive), which add to the total delay in the object.

Pure delay got its name because, in objects where it exists, there is a change in the response time of the object's output compared to the time the input action occurs, without changing the magnitude and shape of the action. A facility operating at maximum load or in which a signal is propagating at high speed has the minimum net delay.

Transient delay occurs when the flow of matter or energy overcomes the resistances between the capacity of the object.It is determined by the number of capacitors and the size of the transfer resistances.

Pure and transient delays degrade control quality; therefore, it is necessary to strive to reduce their values. Contributing measures include the placement of measuring and control devices in close proximity to the object, the use of low-inertia sensitive elements, the structural rationalization of the object itself, etc.

The results of the analysis of the most important characteristics and properties of the objects for automation, as well as the methods of their research, allow to formulate a number of requirements and conditions, the fulfillment of which guarantees the possibility of successful automation. The main ones are the following:

-

mathematical description of object relationships, presented in the form of static characteristics; for complex objects that cannot be described mathematically — the use of mathematical and statistical, tabular, spatial and other methods to study the relationships of an object based on the introduction of certain assumptions;

-

construction of the dynamic characteristics of the object in the form of differential equations or graphs for studying transient processes in the object, taking into account all the main properties of the object (capacity, lag, self-leveling);

-

the use in the object of such technical means that would ensure the release of information about the change of all parameters of interest of the object in the form of unified signals measured by sensors;

-

the use of actuators with controlled drives to control the object;

-

establishing reliably known limits of changes in the external disturbances of the object.

Subordinate requirements include:

-

determination of the boundary conditions for automation in accordance with the control tasks;

-

establishment of restrictions on incoming quantities and control actions;

-

calculation of criteria for optimality (efficiency).

An example of an automation object is an installation for the preparation of molding sands in a foundry

The process of making molding sands consists of dosing the initial components, feeding them to the mixer, mixing the finished mixture and feeding it to the molding lines, processing and regenerating the spent mixture.

The starting materials of the most common sand-clay mixtures in foundry production: waste mixture, fresh sand (filler), clay or bentonite (binder additive), ground coal or carbonaceous materials (non-stick additive), refractory and special additives (starch, molasses) and also water.

The input parameters of the mixing process are the costs of the specified molding materials: spent mix, fresh sand, clay or bentonite, ground coal, starch or other additives, water.

The initial parameters are the required mechanical and technological properties of the molding mixture: dry and wet strength, gas permeability, compaction, formability, fluidity, bulk density, etc., which are controlled by laboratory analysis.

In addition, the output parameters also include the composition of the mixture: the content of active and effective binders, the content of activated carbon, the moisture content or the degree of wetting of the binder, the content of fines - moisture-absorbing fine particles and the granulometric composition of the mixture or the modulus of fineness.

Thus, the object of process control is the constituent composition of the mixture. By providing an optimal composition of the components of the finished mixture, determined experimentally, it is possible to achieve stabilization at a given level of the mechanical and technological properties of the mixture.

The disturbances to which the mixture preparation system is subjected greatly complicate the task of stabilizing the quality of the mixture. The reason for the disturbance is the presence of a recirculation flow — the use of the waste mixture. The main outrage in the mix preparation system is the pouring processes. Under the influence of liquid metal, in the part of the mixture in close proximity to the casting and heated to high temperatures, profound changes occur in the composition of the active binder, coal and starch and their transition into an inactive component.

The preparation of the mixture consists of two consecutive processes: dosing or mixing of the mixture, which ensures obtaining the necessary composition of the component, and mixing, which ensures obtaining a homogeneous mixture and gives it the necessary technological properties.

In the modern technological process for the preparation of molding mixtures, continuous methods of dosing raw (molding) materials are used, the task of which is to produce a continuous flow of a constant amount of material or its individual components with flow rate deviations from the given no more than permissible.

Automation of the mixing process as a control object can be done with the following:

-

rational construction of systems for preparing a mixture, allowing to exclude or reduce the influence of disturbances on the composition of the mixture;

-

the use of weighing dosing methods;

-

creation of connected control systems for multi-component dosing, taking into account the dynamics of the process (mixer inertia and delay), and the leading component should be the spent mixture, which has significant fluctuations in flow rate and composition;

-

automatic control and regulation of the quality of the mixture during its preparation;

-

creation of automatic devices for complex control of the composition and properties of the mixture with processing of the control results on a computer;

-

timely change of the mixture recipe when changing the mixture / metal ratio in the mold and the cooling time of the casting before striking.