Visual systems—how they work and how they work

Since robots are not living organisms like humans, they do not have eyes and brains, and in order to receive visual information, they need special technical sensory devices called vision systems.

Visual systems allow robots receive images of work objects and scenes, transform, process and interpret them using a set of digital devices, so that the robot actuator can then, in accordance with this data, adequately perform the work.

Compared to very sensitive systems, it is vision systems that are capable of delivering up to 90% visual information to a robot for it to function normally. Thus, the problem of implementing machine vision is solved in several steps: information is received, processed, then segmented and described, then recognized and interpreted.

The original information provided in the form of a digital image is pre-processed, noise is removed from it, the image quality of individual elements of a scene or object is improved.The information is then segmented — the scene is conditionally divided into parts that are recognized as separate elements, each of which can be recognized, and then the objects of interest are highlighted.

The selected objects are examined by characteristic parameters, which are described with arrays of information, so further it is possible to select the necessary objects by parameters. The required objects are marked and identified using the program. Finally, the identified objects are interpreted and marked as belonging to one or another group of recognizable objects, after which their visual images are established.

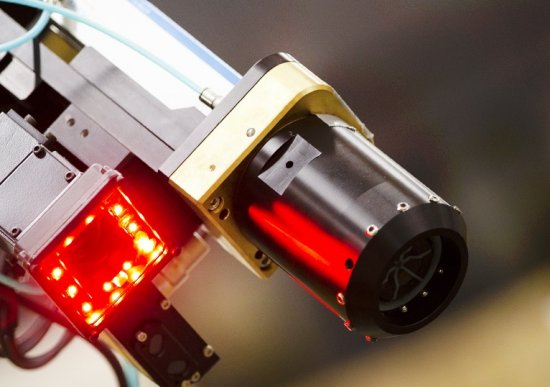

In the technical vision system, the image information, with the help of optoelectronic converters and video sensors, is presented in the form of electrical signals. This is essentially a primary transformation. Usually, the image is read using an optical camera, a sensitive element, a scanning device, after which the signal is amplified.

The information thus obtained is processed hierarchically. First, the image is processed by video processors. Here, the key parameter is the outline of the image, which is set by the coordinates of the set of points that make it up. In addition, the computer that is part of the system generates control signals for the robot.

Video sensors are connected to other parts of the vision system using special cables, such as optical cables, through which information is transmitted at a high frequency and with minimal loss.

The video sensors themselves can have point, one-dimensional, or two-dimensional sensing elements.Point-sensitive elements are capable of receiving visible radiation from small parts of the object, and in order to obtain a full raster image, it is necessary to scan along the plane.

One-dimensional sensors are more complex, they consist of a line of point elements that move relative to the object during scanning. 2D elements are essentially a matrix of discrete point elements.

The optical system projects an image onto the sensitive element, the size of the working area covered by the sensor being determined in advance. The optical system has an adjustable aperture lens to adjust the amount of incoming light and focus sharpness as the distance from the lens to the subject changes.

A variety of optoelectronic devices can act as video sensors, from solid-state transducers to vidicon vacuum tube-based television cameras. The basis of technical vision is the perception and pre-processing of information from these sensors, without the need to resort to artificial intelligence.

This is the lowest level of the system. Next is the analysis, description and recognition - here modern computers and complex algorithmic software are used - the middle level. The highest level is already artificial intelligence.

Practically in industrial robots first-generation vision systems are widespread, providing adequate quality of work with flat images and objects with simple shapes. They are used to recognize, sort and place parts, check the dimensions of parts, compare them to a drawing, etc.

A typical implementation of a vision system looks like this. The working area of the robot, where the parts are located, is illuminated with lamps.Above the work area there is an observation mobile TV camera, from which video information is fed by cable to the main unit of the technical vision system.

From the main unit, the information (in processed form) is fed to the robot control unit. The device performs sorting of parts, their orderly packing in containers in strict accordance with the information received from the software of the technical vision system.

Intelligent and adaptive robots that are actively being developed today, based on second and third generation systems, are capable of working with three-dimensional images and more complex objects, making more accurate measurements and recognizing objects more carefully and quickly.

The main direction of scientific and technical research today is the improvement of vision systems and software and their algorithmic support, the creation of special computers, as well as fundamentally new vision systems, since the use of robotics is increasingly in demand and the field of its industrial implementation is constantly expanding. expands.

Today, more advanced sensitive devices for robots are being developed, capable of transmitting as much external information as possible to the robot. It is now clear that complex sensors can, in principle, perceive scenes and images as a whole, which means that in the future robots will be able to independently form purposeful actions in the space of the work area without additional external stimuli.