Pneumatic devices of mechatronic systems

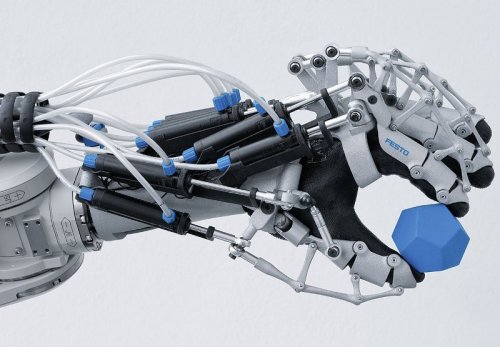

Mobile machines, robots and various mechatronic systems have the ability to move or change the position of their parts thanks to actuators. The direction of movement of this or that part of the system is called a degree of freedom, and the more degrees of freedom the actuator has, the greater the mobility of the machine, robot or actuator.

Depending on the type of drive, a more or less qualitative implementation of the interaction of machine parts with each other, as well as the efficiency and flexibility of its operation, is achieved. Choosing the type of actuator is a difficult task that is decided at the system design stage by robotic engineers and technologists.

One of the popular types of drives used in mechatronic systems — pneumatic actuator… Here gas is used as the working medium, usually compressed air, whose energy drives the mechanism. That's why pneumatic actuators are cheap, reliable, easy to set up and operate, and fire safe.There is no cost to purchase and dispose of the working fluid (air).

However, there are some disadvantages, for example, a possible reduction in working pressure due to leakage due to poor tightness of the pipes, which leads to losses of power and speed, as well as complications in positioning. Nevertheless, pneumatic motors, pneumatic cylinders and pneumatic pneumatic motors are widely used today in robots and mobile machines.

Let's look at a typical device pneumatic drive… Pneumatic drive as such necessarily includes a compressor and an air motor. In this combination, the system can convert the mechanical characteristics of the drive according to the load requirements.

Pneumatic actuators of translational movement are two-position, when the movement of the working body is carried out between two end positions, as well as multi-position, when the movement is carried out in different positions.

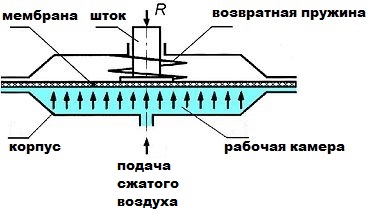

According to the principle of operation, pneumatic actuators can be single-acting (when the spring provides return to the starting position) or double-acting (return, like the working movement, is produced by compressed air). Pneumatic linear actuators are mainly divided into two types: piston and diaphragm.

In a pneumatic piston actuator, the piston moves in the cylinder under the action of compressed air or a spring (the return stroke for a single-acting actuator is provided by a spring).In a pneumatic diaphragm actuator, a chamber divided by a diaphragm into two cavities has on one side compressed air pressing the diaphragm, and on the other side, a rod is attached to the diaphragm and receives a longitudinal force from the diaphragm. Thus, the pneumatic actuator is successfully used in cyclic control systems, for example in manipulators with horizontal stem movement.

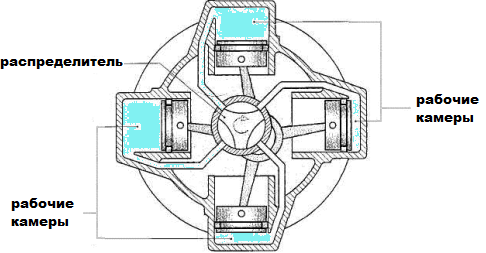

Functionally, the pneumatic actuator can be divided into four units: the air preparation unit, the compressed air distribution unit, the actuator motor, and the compressed air transmission system to the actuators.

In the air conditioning unit, the air is dried and cleaned of dust. According to the program, the distribution block opens or closes (with the help of valves) the supply of compressed air to the cavity of the drive motors.

The valves are usually operated by electromagnets or also pneumatically (if the environment is explosive). The executive engine block is actually cylinders with pistons that rotate or move in a straight line—pneumatic cylinders differing in given displacements, forces, and speeds.

Each engine has its own work cycle, and the sequence of cycles is strictly determined by the technological process and controlled by the corresponding program robot control systems… The system for transmitting compressed air to different devices uses pneumatic drives with different sections, according to the task at hand.

In principle, the transmission and conversion of energy in a pneumatic drive looks like this.The prime mover drives the compressor, which compresses the air. The compressed air is then fed through the control equipment to the pneumatic motor, where its energy is converted into mechanical energy (movement of the piston, rod). After that, the working gas is discharged into the environment, that is, it does not return to the compressor.

The advantages of pneumatic drives can hardly be overstated. Compared to liquids, air is more compressible, less dense and viscous, more liquid. Air viscosity increases with pressure and temperature.

But since air always contains a small amount of water vapor and has no lubricating properties, there is a risk of a harmful effect of condensation on the working surfaces of the chambers. Therefore, pneumatic drives need conditioning, that is, they are given such properties in advance to extend the service life of the drive in which it is used as a working environment.