How CNC machines work and work

The current level of development of technological progress, combined with high consumption and corresponding demand, sets new and new standards for various industries in terms of the quantity and quality of their products. The volumes required today can no longer be provided without resorting to complete automation.

As a result, one of the major innovations of the last decade has been the widespread adoption of metal-cutting machines with CNC — numerically controlled metal cutting machines.

The task of increasing the efficiency of machine-building can be solved on the basis of complete mechanization and automation of production processes, improving the structure of the park of metalworking equipment, by introducing programmed machines, industrial robots, automatic lines and complexes, i.e. ability to quickly change equipment when switching to different types of products.

Industrial robot (automatic manipulator with programmed control) is an automatic machine (stationary or mobile) consisting of an executive device in the form of a manipulator with several degrees of mobility and a reprogrammable device for program control to perform motor and control functions in the production process.

More about robots:

Classification of industrial robots

Types of industrial robots in modern production

The automation of the management of any object consists in subordinating the movement of this object to certain requirements, guaranteeing the best performance by it of its purpose. This organization of the movement of the object is carried out by means of automatic control devices - control machines that include program control systems.

Programmed control consists in the fact that the necessary modes of movement of each controlled object are calculated in advance and recorded in the corresponding information storage devices — memory organs. The control process is reduced to reproducing the movements of the object recorded by this program.

Program control — control by systems that provide a quick transition to any work program by entering it or writing it with a conditional code on the program carrier, with which it is entered into the control device.

Numerical control of the machine — control of the processing of the machine part according to the control program (NC), in which the data is specified in digital form.

Digital control systems (CNC) are built on the basis of hardware and software, focused on the use of microprocessors and modern micro-computers with peripheral equipment, on the use of high-speed automated electric drive that provides reproduction of software trajectories of movement, as well as computer designing, preparing and debugging system and application software.

External view of the WinPCNC model of the CNC Unit

So, CNC (numerical control) is actually a computerized system for controlling the mechanisms of a machine tool, using certain machine commands to perform certain tasks. This technology has allowed many businesses to dramatically increase their production capacity and at the same time reduce the cost of their products.

Programming the order and mode of operation of the CNC machine is carried out using sets of special functions and algorithms understandable to the digital control system. The quantity and quality of commands given to the control system, as well as the programming characteristics of each machine, depend both on the professionalism of the operator and the capabilities of a particular machine, which may initially be limited by its design.

Many routers, for example, allow programming the movement of the work tool, but at the same time do not allow movement of the work table at all. Other machines allow for more programmable actions, so the operator has more control room. Sometimes all that is required of the operator is to change the workpieces in time and monitor the wear of the working tool, and the program will handle the rest.

The device of CNC machines

The design of the CNC machine includes several blocks, each of which, as part of the whole, has its own functional purpose. There may be additional units that introduce individual characteristics into the unit system. Suppose a CNC lathe has the following basic components: base, bed, head rest, tail fluid, cutter head, gear drives, thread sensor, control panel.

The base is a cast rectangular part on which the bed is mounted and which provides the machine with strength and resistance to vibrations. The bed is the main part of the lathe, which unites all its components and mechanisms. It consists of a pair of walls rigidly connected by transverse elements.

There are guides on the bed, in addition, the gearbox and the rear part are fixed here. The tail and support with the apron can move along the guides, depending on the type of working tool. There is a bearing in the spindle head, thanks to this design, the workpiece is fixed and rotated.

The automatic cutting head implies a sequential installation of the cutting tools in the working position. Driving gears of the main movement, transverse and longitudinal transmission.

The electric motors transfer the rotation of the rotor, which, thanks to the spherical screws, is converted into a linear movement of the blocks. The tail holds the center of the workpiece to be machined. The tap sensor is located on the tray. The control panel is designed for operator convenience and process monitoring. There can be several control panels.

Programming fixed spindle drives boils down to turning on, off and switching the appropriate contactors.To do this, it is enough to record the signal of the «on» and «off» commands.

Speed control of the main spindles is most often required to ensure that the metal is processed at the optimum cutting speed. In this case, it is necessary to adjust the angular speed so that the peripheral speed with which the cutting is performed has a constant optimal value.

Programming the control of feeders is a much more important and complex task, as it ensures the performance of the main function of the machine — forming the shape of the product.

Standard coordinate system of CNC machine tools

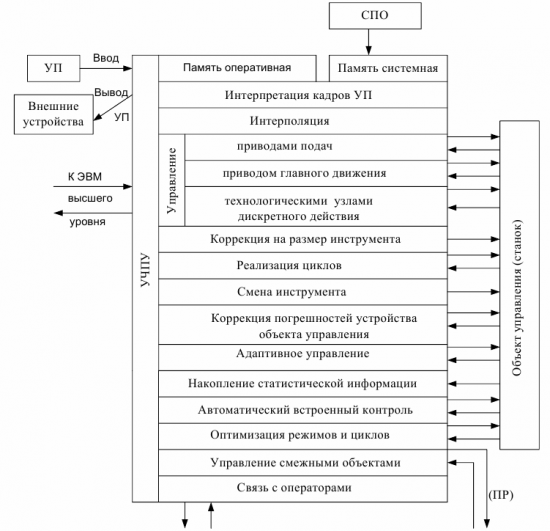

Functional diagram of CNC machine control

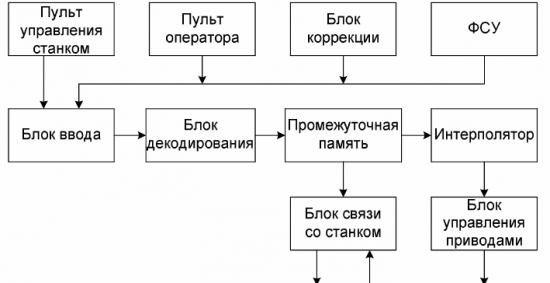

Schematic implementation of NC class (SNC) CNC algorithms

Alan Bradley's PCNC-1 system architecture with CNC

The advantages of CNC machines

The main and obvious advantage of a CNC machine, compared to a conventional machine, is the highest level of production automation, which minimizes human intervention in the process of manufacturing parts.

By definition, the CNC machine is capable of working autonomously and almost continuously, without getting tired around the clock, and the quality of the products will not fall because of this. If the work was done by a person, he would be tired, it would be necessary to change the lathe, the ubiquitous human factors, errors, etc. This is not here. The operator only prepares the machine for work, places and removes parts, adjusts the tool. One person can operate several machines in this way.

In addition, the highest flexibility of CNC machines should be noted. To produce different parts, the operator only needs to change the work program of the machine.In addition, the program is always ready to run an unlimited number of times, while the program does not have to be edited each time.

High accuracy and repeatability no longer depend on operator training, but on the quality of the program used. This is a huge plus, compared to conventional metal cutting machines, allowing the production of thousands of parts identical in form and quality, and without reducing this quality.

Some parts cannot be made by hand on a conventional machine due to complexity or high cost, and on a CNC machine it is just a matter of choosing the right program. As a result, CNC machines enable one to quickly and efficiently obtain a part of almost any complexity and in principle in any quantity. There is only one condition — the part to be manufactured must be pre-designed using a computer.

See also:

Electric drives for CNC machines

Electrical equipment for CNC drilling machines

Electrical equipment of CNC lathes