Capacitive level sensors — device, principle of operation, application

Capacitive level sensors are primarily used as a means of monitoring the level of various liquids. The control process is based on the fact that each liquid has a certain dielectric constant. Therefore, the principle of operation of a capacitive level sensor is as follows.

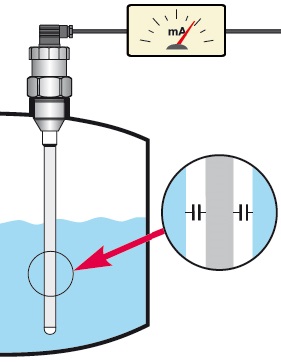

The main element of a capacitive level sensor is a special highly sensitive capacitor that can change its capacitance depending on the environment in which it is placed. The sensitivity of the capacitor allows the sensor to work equally effectively with both dielectric fluids and fluids with minimal dielectric constant.

The sensor is simply installed in a tank for a liquid material whose level in that tank (for example, in a pipe) needs to be monitored. The current dielectric constant of air is taken as the basic dielectric constant. And as soon as the liquid comes into contact with the sensitive element of the sensor, the capacitance of the sensitive capacitor will change.At this moment, the sensor will work — the control level of the liquid will be fixed.

By the way, capacitive type level sensors are able to respond to liquid without direct contact of the sensitive element with it. After all, fixing the change in the dielectric constant can also be done by the dielectric material of the tank body in which the liquid level varies. Monitoring can be done, for example, through the lid, wall or bottom of the tank, as soon as the liquid reaches the point where the sensitive sensor element is installed.

Capacitive level meters with coaxial electrodes are used for level measurement in non-conductive media. The disadvantage of the coaxial sensitive element is its poor filling with a controlled substance, especially with increased viscosity of the medium and the presence of solid impurities.

Sensors are produced in different versions: in shape, size, design of the sensitive element, as well as in the design and size of the housing and the type of installation of the sensor (built into the wall or cover, placed next to the container, placed on a suspension in the container).

In the case of using one electrode as a sensitive element, the role of the second electrode of the capacitor is played by the grounded wall of the tank, if it is metallic, or a special grounded metal electrode, if the wall of the tank is made of a dielectric. Single electrodes can be rigid rods or flexible cables.

To measure the level of a conductive medium, the measuring electrode is covered with an insulating layer. As a rule, fluoroplast is used as insulation.

Capacitive liquid level sensors are used in a wide variety of modern industrial areas because they are compatible with almost any liquid. This is agriculture with its liquid fertilizers and irrigation systems. This is the food industry (milk, water, beverages).

In the petrochemical industry, it is necessary to control the level of petroleum products. In pharmaceutical products, liquid preparations. In many industries, it is extremely important to control the level of water, including underground, as well as water in storage systems, water supply, sewage and sewage in enterprises and simply in buildings.

In this way, the sensor is able to measure the level of a liquid product and, if necessary, interacting with the automation, maintain the required value. It can monitor the filling of the container with liquid and the process of passing the liquid through the pipeline, as well as monitor the flow. Thus, the capacitive liquid level sensor is an indispensable solution for automation systems in all types of enterprises.

A number of advantages distinguish capacitive sensors from other types of level control devices. Capacitive sensors are compatible even with chemically aggressive and flammable substances.

They can work with products with almost any physical properties, with tanks of any volume, shape and size (due to the possibility of non-contact interaction). The room can be smoky, dusty, and there can be high humidity in the air, which does not interfere with the operation of the sensor.

The sensor is easy to place and very easy to maintain.As a result, the life of the sensor can be measured in years, and the accuracy and reliability, when used correctly, will remain unchanged.

Of course, capacitive sensors also have disadvantages. For example, they are sensitive to foaming, build-up of material or deposits, which can cause false alarms. Regular maintenance of such sensors is therefore required. Of course, they are more expensive than other types of sensors.

In any case, before installation, the sensor must be precisely adjusted and during operation you must monitor its condition. Then the reliability and accuracy of the control will remain the best.