Industrial robots and the benefits of their implementation in production, the importance of robotics

The world is becoming increasingly digital and progressive. This can be judged, for example, by the fact that the number of robots installed in industry around the world has more than tripled in the last ten years.

Robotics is a new tool for complex mechanization and automation of production, technology of the latest generations, giving the highest efficiency.

Robotics is a new complex scientific and technical direction, including development, creation and use manipulators, robots and robotic technological complexes, as well as the related organizational, socio-economic and psychological aspects that require a new scientific approach. Successfully working in various fields, it gradually proves its advantages.

Robot automation for productivity, flexibility and safety

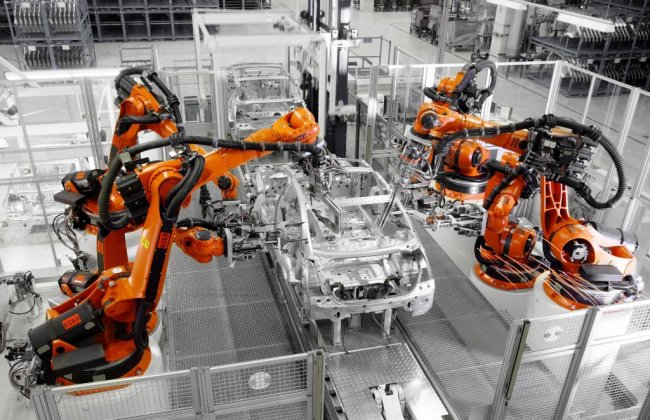

The idea of replacing human labor with machines has been known since ancient times.The industrial robot is another step in the development of flexible automation to optimize production, with the ability not only to continuously repeat the same operations with guaranteed accuracy, but also with the possibility of simple reprogramming in the event of a change in the user's production program.

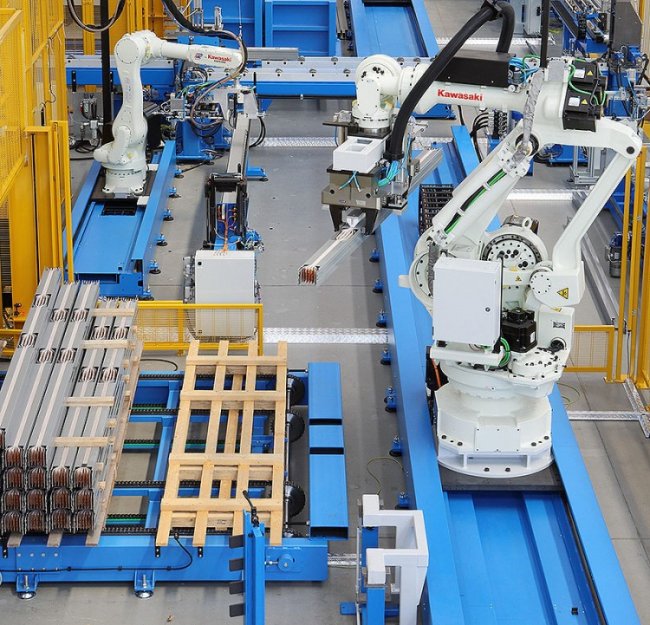

The concept starts with simple workstations, where the robot is equipped with a positioner to place bodies and position parts in two or more stations, to the entire robotic production line, where the function of bodies, including loading and unloading of parts, is controlled by robots.

Important helpers in the world of modern automation today are widely used assistive systems such as imaging systems or cameras that allow robots to remove and manipulate large parts.

However, the reliability of robots, their software, high performance and ease of operation are essential prerequisites for the proper functioning of these devices and systems.

The level and methods of production automation significantly depend on its type and scale, and if in mass and large-scale production the use of automatic lines is most justified, then in medium-series and small batch and single production complex automation made possible with the advent of computers, CNC machines and industrial robots.

On the base technological equipment with digital control and assemble industrial robots, multi-product lines, sections, workshops called flexible automated manufacturing.

The main principle for building such flexible production facilities is modularity.Agile manufacturing automation has evolved from simple to complex — originally designed and implemented flexible manufacturing modules (PMM), are built on their basis flexible production complexes (HPC) and finally flexible automated manufacturing (HAP).

New generation robots are easier to install and program and at the same time easier for them to communicate with each other

Their further development is the creation of almost abandoned automatic production, where flexible automated production is supplemented by computer-designed production of manufactured products (CAD) and technological preparation of their production, planning and dispatch control (ACS).

The main structural unit of flexible production modules of any complexity are robotic technology complexes (RTC), which can be formed on the basis of one industrial robot providing individual or group maintenance of attached equipment or a complete product processing cycle (for example, welding), or on the basis of several industrial robots performing interconnected operations.

The versatility of most industrial robots enables their wide use as part of robotic technological complexes for various types of production.

Advances in robotic technology are driving the growing use of robots

The intensive adoption of industrial robotics now and in the future is due to a number of reasons.

First of all, the creation and widespread introduction of industrial robots and manipulators, which make it possible to intensify various technological processes and operations, to exclude the use of manual low-skilled and monotonous labor, especially in difficult, dangerous and harmful conditions for people.

In the coming years, the industry should ensure a significant increase in production through the introduction of new types of equipment and progressive technologies. Although the share of manual labor in industry has declined, there are still a million people in manual labor in the world today.

Numerous studies of working conditions show that about 30% of workers are adversely affected by noise, 30% have to work according to a strictly regulated regime, 25% are exposed to moisture, heat or cold, 20% work in physically uncomfortable positions or under smoke and fume conditions. 20% are forced to make great physical efforts, and 15% work at night.

These stressors often act in combination; therefore, about 40% of workers are simultaneously affected by two and about 25% by three or more factors. Accordingly, the introduction of robotics provides a significant reduction in the proportion of manual, heavy, harmful and tedious work. (social factor).

Industrial robots can perform tasks that previously could only be performed by humans

In addition, the nature of production has changed — about 80% of products are produced in small batches. Therefore, production automation becomes one of the essential levers for increasing labor productivity in small-scale production. (economic factor).

Robotics allows you to solve the problems of two- and three-shift labor, increase the load factor of the equipment and the rhythm of its work, improve the quality of products and reduce their cost, mainly in small-scale production.

It creates prerequisites for moving to a qualitatively new level — creation of flexible automated production systems that allow rapid reconfiguration to perform operations with different sequences and nature of actions and work with minimal human involvement.

There is an even greater rapprochement between man and machine: they increasingly work hand in hand and without a protective fence.

The main technical characteristics of industrial robots are determined by the field of application and the production conditions for which they are intended.

Description and characteristics of modern industrial robots are contained in the articles: Industrial robots in modern production and Classification of industrial robots

Studies show that when used in certain operations, an industrial robot, depending on the work shift, replaces 1-3 workers, increases labor productivity by 60-80% and reduces production preparation costs by 45-50%.

When used in groups, the efficiency of industrial robots increases sharply: productivity increases by at least 3 to 5 times, and in some cases by 8 to 10 times, capital investment and maintenance costs are relatively reduced, the intensity and rhythm of production is shifted, increase of product quality, the number of rejects is reduced.

The automotive industry is leading the way: using intelligent manufacturing solutions and industrial robots instead of the assembly lines that have dominated traditional manufacturing for more than 100 years.

Among the areas of reducing manual and heavy physical labor, in addition to robots, an important place is also allocated to the simplest devices — manipulatorsas a means of complex mechanization of production.

In production, where there is no need to protect a person from the environment and frequent loading and unloading of equipment, command-controlled manipulators have become widespread, characterized by the fact that the human operator sequentially turns on the drives of each link separately.

Such robotic manipulators are the simplest in design, relatively inexpensive, and their use does not lead to a change in the technological process, as they easily fit into the existing technology. Versatility, low cost and high efficiency in loading and unloading operations are their distinguishing qualities.

Modern robotic manipulators provide new opportunities in the world of work

Many types of work, in particular mechanical assembly, construction and finishing, lifting and transport, storage and repair can be mechanized in the near future exclusively with the help of manipulators.

According to calculations, meeting the industrial needs of robotic manipulators will reduce the number of manual workers in more than 30 professions: locksmiths by 4%, repairmen by 3, packers by 5, warehouse keepers by 2.5, transporters by 3 and loaders — by 5%

As a result of network innovation, more and more robots are appearing in manufacturing sectors that have only recently discovered automation. Examples of this are the food industry, the textile industry, the woodworking industry and the plastics industry.

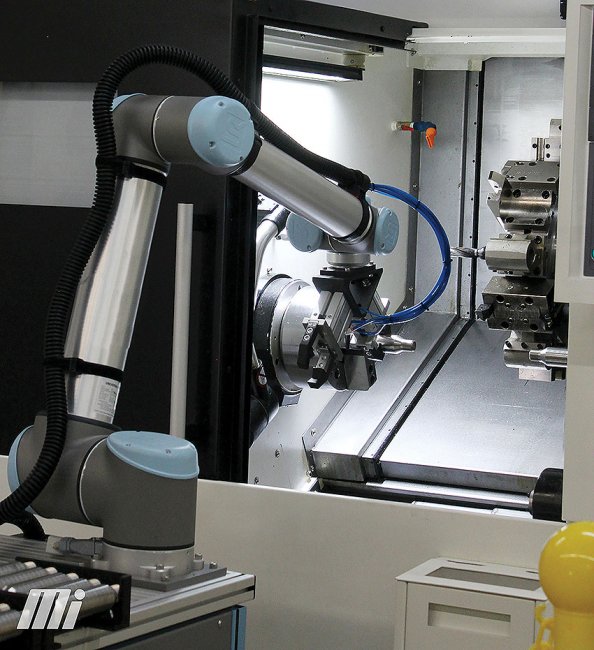

Until recently, the use of standard types of industrial robots was accompanied by a number of safety and accident prevention measures. In this regard, a new type of robots (collaborative robots), sometimes called "cobots", is a completely revolutionary solution.

Research and development of collaborative robots has focused from the beginning on safety and at the same time on the possibility of its integration into work lines with human operators.

Even in the last decade, industrial robots were on the fence. But then it appeared collaborative robots… The essence of the term "cooperation" means that he can work together with people.

What might this look like and why is it not dangerous? The design of the robot is such that it has limited power and output, including a function that immediately stops the robot when a collision is detected, which can be done in several ways. In many applications, this robot can be used without safety protection.

Today, robot manufacturers can offer their customers a type of robot that meets the most stringent requirements in terms of its characteristics and at the same time has a number of other advantages that can be highlighted:

- Simultaneous operation with a human operator,

- space saving,

- easy setup,

- high performance,

- accuracy,

- reliability.

Collaborative robots are still new. The possibilities of their application have not yet been fully revealed.Currently, cobots are most widely used in the electronics industry, but their capabilities have been successfully applied to other industries as well. Thanks to their flexibility and ease of use, they will also find their place in the logistics and service industries. Our research shows that these non-manufacturing areas will account for 21.3% of cobot sales by 2024. Our friendly little cobots have the potential to grow significantly compared to other types of robots!

— Jan Zhang, CEO of Interact Analysis

If a worker performs a repetitive task for many hours a day, it is often relatively easy to replace a collaborative robot in a relatively short period of time, thanks to simple programming and configuration and without all the safety measures required for traditional industrial robots.

For the same reasons, the collaborative robot is also much more affordable (not only the cost of the robot is lower, but also the installation cost by eliminating the time required to maintain and configure the robotic cell equipment) and therefore it is easier to justified financially.

The best examples of successful implementation of such robots are in production facilities where there are several stations performing the same type of processes, for example technological processes with multiple CNC machines.

At present, the creation and implementation of robotics should be recognized as one of the priority areas of industrial development.

More than a thousand companies are engaged in the development and production of industrial robots. All major companies are starting to invest in industrial robots.New companies specializing in these products are being created, as well as intermediary companies for the introduction of industrial robots.

In all developed countries, national associations for industrial robotics have been established, and in some countries work in this field has been raised to the rank of a state program.

In Russia, the National Association of Robotics Market Participants (NAURR) was established, the purpose of which is to develop the robotics market, expand international relations and popularize robotics.