Development of automation, HMI and OIT interfaces

HMIs and other operator interface devices are designed to work in harsh environments and combine the best elements of traditional interfaces with modern commercially available technologies.

Industrial machine and process automation systems must monitor conditions, issue commands to equipment, and coordinate control. Developers implement these functions by combining a wide range of industrial automation technologies, such as sensors and instruments, input / output (I / O) modules and digital controls. However, even the most advanced machines do not operate on their own, meaning that some form of operator interface must be supplied with the automation system.

The electronic devices that allow operators to communicate with automated systems are called together human machine interface (HMI)… Sometimes more specialized devices built into a computing platform other than a PC can be invoked operator interface terminal (OIT).

The integration of HMIs and OIT terminals into automation systems is critical for many reasons. They offer many more interface options than simple panel units, and if changes need to be made, the HMI or OIT can usually be reconfigured or reprogrammed at a lower cost.

However, this extended functionality of the operator interface still has some drawbacks and increases the cost of the HMI and complicates its maintenance. To overcome these shortcomings, the latest HMIs are designed with proven traditional solutions using the latest commercially available technologies.

Weaknesses of traditional HMI and OIT terminals

The first generation of HMI and OIT was designed to allow users to start and stop devices, understand system operation and make changes.

Features such as alarm and event logging, historical data storage, and trending have been added over the years. HMI and OIT terminal configurations can be copied and saved, and new devices can be deployed relatively quickly if the original device is damaged or out of order.

With improved networking capabilities, especially Ethernet and Wi-Fi, HMIs no longer need to be installed in close proximity to resources. Multiple HMIs can be installed in a suitable location such as control room, car and offices.

These HMIs, along with OIT terminals, had many advantages over wired panels, but they also had several disadvantages.

Examples include the following:

- limitations imposed by special hardware and software,

- high initial costs,

- ongoing maintenance and upkeep costs,

- complexity and cost of license management,

- expensive training of technicians and operators,

- the complexity of integrating multiple platforms,

- backward technologies.

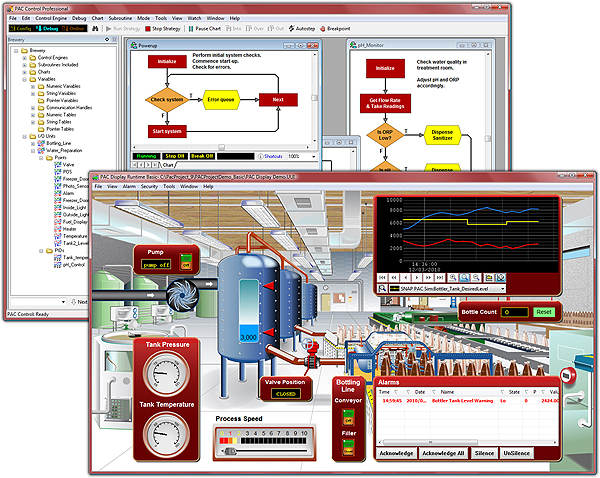

Operator interface terminals, typically ad hoc and closed systems, are rapidly being replaced by more open alternatives. All images courtesy of Opto 22

Specialized OIT terminals will likely use special hardware and software. Manufacturers offer these devices to provide adequate control of the management system interface in a relatively self-contained design.

Because the devices are designed specifically for the industrial market, they cannot reap the commercial benefits to the extent that they are typically used for consumer electronics, and are therefore more expensive in terms of price/quality ratio. However, they are traditionally designed for industrial environments and provide a practical and reliable solution.

Due to the availability of more advanced PC-based HMIs, this equipment is perceived as good value for money compared to previous solutions and provides the user with flexibility and connectivity. However, one of the disadvantages was the increased need for ongoing service and maintenance.

Users now expect perfect graphics, frequent free updates and improvements to the operating system and device applications.

Advanced consumer electronics have driven end users to rely on multimedia and intuitive HMI on all types of devices with convenient mobile access. Designed for Ethernet and USB connectivity, the Groov Edge plug-in enables developers to create connectivity and data-driven applications for automated devices and the Internet of Things (IoT).

However, innovation in the industrial market has been somewhat slower since it is relatively small compared to the much larger consumer market—not to mention much more conservative than the high-end personal electronics market.

New HMI technologies

The latest generation of HMI addresses each of these shortcomings by adapting commercial technologies, incorporating and building on the best features of previous generations of HMI and OIT terminals.

Possible benefits:

Open Source Technology: Ideally, a modern HMI combines the reliability and ease of use of a traditional OIT terminal with the performance and cost of a PC-based HMI.

This combination is possible if the hardware platform is based on an open source real-time operating system such as Linux that does not require any acquisition costs or license fees.

Small footprint, hot-swappable components can make this platform easy to operate. The well-designed hardware allows it to be used even in harsh industrial environments while providing PC-class performance.

Available Configuration: Customization is possible, but not required, as modern HMI equipment includes built-in standard features to meet most needs.

PC software for HMI configuration is affordable and does not require any restrictions on license fees. The end user can focus on using the HMI where it is most appropriate without worrying about markup or runtime limitation.

Ease of use: A set of development options makes the advanced HMI easily accessible for new developers to build basic applications, but can be fully extended for experienced programmers to develop their own applications with additional secure access to the shell.

OEMs often need this flexibility to program machine-oriented algorithms and even custom algorithms in C/C++, Python, and other languages.

Integrated display and flexible ports: The integrated display available on some devices can be more than enough HMI for many applications, although the HDMI connection allows a larger local screen to be used if needed. In addition, multiple Ethernet and USB ports and I / O modules make it easy to connect to any operating device or system.

Network and cloud connectivity: Modern HMIs can provide even more power when users use network and cloud connectivity. Data can be securely shared between databases and systems, and HMI visualization can be extended to any authorized computer or mobile device. which can host a web browser.

Mobile devices: Mobility is another key element of modern HMIs. Once the base unit is installed and configured, any mobile device can safely connect and become another human-machine interface, giving technicians and operators greater flexibility. Developers can focus more on maintaining and managing the HMI while eliminating the cost and complexity of the underlying platforms.

The latest generation of HMI combines the best features of traditional products with modern open source hardware, software and networking technologies to address these challenges.

Because these new HMIs can be easily and seamlessly networked and deployed on any typical mobile device, end users are finding that advanced technology meets their needs at a price they can afford.

Benson Hoagland, Vice President of Marketing, Opto 22 (a manufacturing company specializing in hardware and software products for industrial automation, remote monitoring and data acquisition).