Ensuring safety when using industrial robots

The industrial robot is subject to increased danger. The first case of human death from the actions of a robot was registered in a Japanese factory. The service technician, who was in the work area, troubleshooted the router with the robot off and connected the robot to the machine. The manipulator, moving at a speed of about 1 m / sec, pressed the regulator and crushed it.

On average, there is one accident per 100 industrial robots per year. Approximately 3 traumatic situations occur during 14 days of operation of a robotic technological complex.

The main causes of injuries during the work of robots are:

- unexpected actions of the robot in the process of its training and work;

- errors in robot repair and setup;

- the presence of the operator in the working area during the automatic operation of the robot;

- placing the control panel in the working area of the robot;

- malfunction or shutdown of protective devices.

Most injuries are caused by control device malfunctions and programming errors.

In the short story "The Tramp" (1942), the American science fiction writer Isaac Asimov formulated three laws for the safety of robotics:

- the robot must not harm a person by its actions or inactions;

- the robot must obey the commands given to it by the person, except when those commands contradict the first law;

- the robot must take care of its safety if it does not contradict the first and second laws.

There are three possibilities for direct contact between the operator and the robot that can take place during programming (teaching) and operation of the robot: direct work with the robot, as well as during its repair and maintenance.

The main means of ensuring safety is to prevent the simultaneous appearance of a person and moving parts of the robot at one point in the robot's working area. Protective devices must stop the movement of robotic elements in those areas of the work area where the person is located. If the power suddenly goes out, the movement of the robot's links should stop.

The working area is the space in which the working body of the manipulator or robot can be located. It depends on the dimensions of the links, their movements and the kinematic scheme of the manipulator. The working area is set in the manipulator description.

Three levels of protection zones are most often defined:

- detection of the presence of an employee at the border of the work area of the robotic station;

- detecting the presence of a person in the coverage area of the station outside and within the range of movement of the robot;

- direct contact with the robot or close to its hand.

In the path of the suspended robot, nets must be installed to protect people and equipment from the sudden fall of the transported objects. Program execution monitoring devices control the occurrence of robot links at specific points in the work area. They can be path switches that are triggered when a link passes through a point.

The devices for controlling the interaction of the robot with the environment turn off the link drives when the resistance to movement increases, for example, when one of the links touches an obstacle. Torque sensors or tactile sensors are used to measure the load.

Fencing of the work area is carried out with the help of mesh fences and light barriers. Mesh fences are most often used to prevent people from entering the work area.

However, it is not always possible to completely fence off the area with the robot. If, for example, receiving conveyors are used, that is, surfaces that are not fenced in, through which unauthorized persons can enter the work area. Such areas are protected by optical (light) barriers.

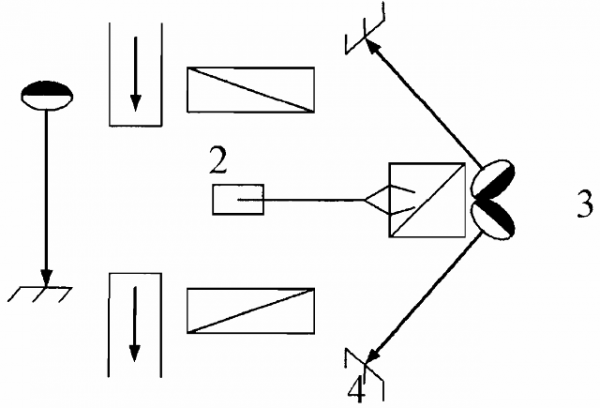

The light barrier is a stand for light emitters and a stand for photodetectors. If each photoreceiver receives light from the corresponding light emitter, then the robotic complex works. The presence of an object between the light emitter mount and the photodetector mount will cause the light beam to cross, causing the equipment to shut down.

Several light barriers are used to enclose the robotic complex on all sides.

Fencing the work area with light barriers: 1 — technological equipment, 2 — robot, 3 — light emitter, 4 — photo detector

Entrance areas to the work area are secured with electric locks along with an automatic locking and unlocking system. In this way, the shutter is released only when the robot is disabled. Additional safety buttons in the working area can protect a person from uncontrolled activation of the robot by unauthorized people.

The security system is usually supplemented by the use of warning lights and sirens, and the robot itself and its moving parts are brightly colored.

Additional protection is the use of devices that detect the presence of a person in the robot's working area.

Various human presence detection systems are currently in use. For example, it can be: detection of microwave radiation (using the Doppler effect), detection of passive and active infrared radiation, vision systems, changes in capacitance, pressure, use of ultrasound, etc.

To ensure safety when using industrial robots, workplaces use a hierarchy of work and therefore different responsibilities. All activities require appropriate training. Three types of employees are delegated to work with the robot: operators, programmers and maintenance engineers, each with different tasks and powers.

The operator can turn the robot controller on and off and start the robot from the operator panel. It is strictly forbidden to enter the working area of the robot. This activity is intended for programmers and service engineers with appropriate training.In addition, the programmer and engineer are responsible for robot management and programming, commissioning and maintenance.