The key to increasing productivity is the development of management systems

Mobile computing, contextual data, and modular architecture will transform the look and feel of control systems and improve overall plant productivity, helping to reduce the risk of layoffs for experienced workers.

Organizations invest in management systems with the expectation that they will function as expected for many years. The pace of change in management systems is accelerating and the next decade will bring enormous changes.

Understanding these changes is important for organizations seeking the best performance and return on investment in control systems.

For decades, the control system has been limited to physical hardware: wired inputs and outputs, connected controllers, and structured architectures, including dedicated networks and server configurations.

Reduced computational and sensor costs, the development of network and wireless infrastructure, and distributed architecture (including the cloud) are now opening up new possibilities for control systems.

In addition, emerging inclusion and manufacturing standards, such as Advanced Physical Layer (APL) and Modular Type Package (MTP) interfaces, will drive significant changes in the design and use of enterprise management systems over the next decade.)

Even with changing times and technology, the equation for success remains the same: Choose a reliable and easy-to-use control system while providing access to new technologies to improve productivity.

The flexibility of the management system reduces the risks associated with the retirement of experienced workers

Over the past decade, the industry has seen the retirement of professionals and taken steps to mitigate the effects of the loss of experience. These changes have led to a reduction in the number of workers in the workplace in a number of industries.

At the same time, with a host of new scanning technologies and high-bandwidth data transfer capabilities, businesses are collecting more data than ever before, and organizations want to get more value from that data to help them improve business performance and improve differentiation.

This includes more flexible product delivery options, optimized quality and consistent production volumes, as well as improved operational safety and environmental compliance.

In response, many organizations will extend their management architecture to a more geographically distributed infrastructure, allowing small, centralized teams of professionals to provide support across their entire fleet.

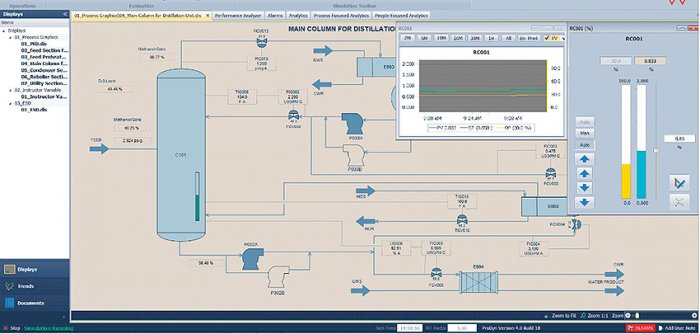

Critical data from the control system will be visible across the enterprise, enabling small teams to provide support for multiple geographically dispersed locations. All images courtesy of Emerson

These internal experts can be supplemented by OEM experts who are allowed secure access to relevant aspects of this infrastructure.

One element of this distributed architecture is the cloud, be it private, public or hybrid. The gradual migration of non-essential architectural controls to the cloud makes it easier for organizations to work more efficiently and make better decisions.

Cloud users get more value from their data by leveraging expertise from around the world, whether in their own business or from many service providers.

In addition, centralizing data in the cloud offers the advantage of lower life-cycle costs, lower maintenance requirements, and the elimination of isolated data islands.

A shift to centralized control will require a change in management system strategy, even if actual primary control is not transferred from the operational level.

The tools experts rely on (system configuration, device monitoring, alarm management, real-time data and event history, digital twins, repair management systems, etc.) are elements of the management system.

Many of these tools do not affect day-to-day management, but are tied to the management system, which in turn is tied to a physical location in the enterprise. In the future, it will make more sense to host these components in the cloud.

Centralized data and cloud architectures will also facilitate rapid deployment of new technologies.

Data centralization makes it easy for organizations to implement one-way secure mobile access to management system data, allowing enterprise staff to track it anywhere

Easy integration increases efficiency

The key to success is finding platforms that allow the introduction of new technologies with minimal integration and technical costs. The most advanced controllers can operate as stand-alone controllers and have the ability to integrate into a larger management system, allowing organizations to develop architecture and management capabilities in relation to processes and products.

Leading industrial companies are also reducing the need for modular manufacturing with new plug-and-play technologies.

The MTP technology, developed by NAMUR (Association of Users of Automation Technologies in Manufacturing Processes), uses existing technologies to create interfaces for formulated integration of different systems and simplifies the design of modular systems.

MTP standardizes the interaction between production modules and the control system, allowing enterprises to combine components.

The control system will continue to play a critical role in the management and optimization of these diverse but more integrated modular systems.Using these integration standards is a key element in achieving the best possible result.

Advanced controls and digital twins improve work efficiency

Control systems now include many more analytical tools and decision support to help operators make more informed decisions across a wider range.

Instead of making decisions, making them, and hoping they are the right choice, operators will use simulation to validate key decisions in an autonomous environment.

For example, an operator in a plant may notice that a process variable is trending badly. The operator uses the digital twin to test the new routine and then discovers that it is too close to the break limit.

To avoid this scenario, it will use digital twinsto try other alternatives and find a way to safely negotiate the process parameters.

The operator helps to make the right decision without testing anything on real processes and devices. The digital twin will be available at the workplace and in the cloud and will become a standard part of most projects.

Could artificial intelligence (AI) be the next stage in the development of control systems?

Control systems have evolved continuously over the decades. Artificial intelligence (AI) technologies are helping to develop the next generation of some control systems.

Proportional integral-derivative (PID) controller can be interpreted as a separation of capabilities: the proportional element displays the signal, the integral element approaches the set point, and the differential element can minimize the overshoot.

While a management ecosystem can be a complex web of interconnected technologies, it can also be simplified by viewing it as an ever-evolving branch of a family tree. Each control system technology offers its own unique features that were not available with previous technologies.

For example, feedforward improves PID control by predicting the controller output and then using the predictions to isolate errors due to process distortion from signal noise.

Model Predictive Control (MPC) adds further capabilities to this by breaking down predictions of future control intervention outcomes and controlling multiple correlated inputs and outputs.

The latest advancement in control strategies is the introduction of artificial intelligence technologies that take industrial control systems to the next level.

Artificial intelligence technology can be extended to solve any complex problem that can be modeled, for example to manage intermittent production stoppages in factories supplying the oil and gas sector, and to optimize and manage the operations of refineries and chemical plants .

To get the most out of these new solutions, organizations need non-standard and easy-to-use automation platforms to help them evolve with changing market and industry conditions.