How the equipotential bonding system works and works

We live in a world where it is impossible without electricity. In our houses and apartments, there are a large number of different household electrical appliances that greatly facilitate human life, and some of these appliances have metal parts. In fact, the conductive parts of any device always have a certain electrical potential, but when this potential is the same on almost all surfaces in the room, then no problems arise.

But what if the insulation was broken somewhere, as a result of which the conductive core came into contact with a conductive element of the device, for example, a handle or the wall of its case? Or did static electricity cause electrification? Or maybe the reason is the stray currents of the grounding system? There is a real danger to human health here.

If a person accidentally touches such an object while simultaneously touching some other conductive surface that at that moment has a different electrical potential, he will come under the influence of a potential difference and experience a risk electric shock… Even currents flowing in the grounding system are capable of creating dangerous potential differences.

To prevent the risk of electric shock from such objects, an equipotential bonding system must be arranged in the facility to ensure the same potentials on all potentially dangerous metal surfaces. This system is designed to electrically connect to the protective neutral conductor PE all metal objects that can, in principle, be accidentally energized.

Chapter 1.7 of the EIC states that the purpose of protective equipotential bonding is electrical safety achieved by imparting equal potentials to conductive parts by electrically connecting them to each other and to earth. By combining in this way with the help of protective conductors in one circle all conductive structures and elements of the building, communication and engineering networks, as well as the grounding device, an effective system for equalizing the protective potential can be obtained.

Each protective element is connected to the equipotential bonding system with a separate wire by means of a bolt, clamp, clip or welding. Direct protective conductors can be laid separately or be part of the supply lines. In addition, each point of connection of a metallic element to the equipotential bonding system must not only be protected from corrosion and mechanical damage, but must also be accessible for both testing and inspection.

Basic equipotential bonding system

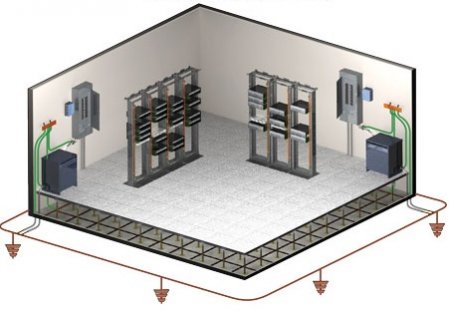

Large conductive parts (which under normal conditions should not be energized) directly to the building structure, as well as metal pipes for sewage, gas and water supply - are combined in the main equipotential bonding system and connected to the main earth bus. Thus, the entire system consists of: grounding device, main grounding bus, neutral protective conductors and equipotential bonding conductors.

A complete list of elements of electrical installations with an operating voltage of up to 1000 V, which must be connected to the equipotential bonding system, given in PUE… The main earthing busbar is arranged separately in the building or is installed in the entrance-distribution device of the building.

The requirements for the installation of the main grounding bus are as follows: it must be located close to the protected object, inaccessible to accidental contact, while it is necessary to have access for inspection and maintenance. If we are talking about the installation of GZSH in the input distribution device, then here it is neutral PE conductor acts as the main ground bus.

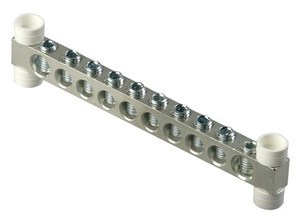

The protective neutral conductor and the neutral conductors of the distribution network of the facility are connected. If the main ground bus is installed separately, then only the protected conductive parts of the building structure are connected to it. The cross-sectional area of GZSh should not be less than the cross-sectional area of the neutral protective conductor of the power input line. The main material for grounding the bus is copper, aluminum or steel. Section for copper — at least 6 sq. Mm, for aluminum — at least 16 sq. Mm, for steel — at least 50 sq. Mm.

So neutral protective conductors and earth loop are connected to the main earth bus. Conductive elements of the building, water pipes, ventilation systems are connected radially to the GZSh, and each element is a separate solid (without built-in switching devices) potential equalization wire, so it remains possible to disconnect any of these elements if necessary.

Traditionally, wires are marked with bright yellow / green insulation markings. Those parts of the communication elements which are introduced into the building from the outside must be connected to the main earthing bus as close as possible to the point of their entry. Each wire must have a label indicating which conductive part in the building this wire connects to the GZSH.

Additional equipotential bonding system

In those places in a building where the presence of an accidental potential difference on objects is particularly dangerous for people (such as a shower cabin, bathroom or sauna), a sufficiently high level of electrical safety is required compared to other premises. Therefore, an additional equipotential bonding system is installed in such places.

An additional potential equalization system is designed to combine all open and hidden conductive elements, as well as neutral and protective wires of contacts, switches, lamps, etc.

The shield wires go to a common busbar located in the equipotential bonding box and do not each extend to the shield as one might think. Several protective conductors are connected to one busbar with a cross section of 10 sq. mm or more.The equipotential bonding box is in turn connected with a PE-conductor with a cross-section of at least 6 sq. Mm-to the grounding bus located inside the shield (input switchgear).