Bare wire structures for overhead power lines

Overhead line conductors, as well as cables reinforced at the top of the power line supports to protect the conductors from atmospheric waves and direct lightning strikes, work in difficult conditions, as they are outdoors and exposed to various atmospheric phenomena ( wind , rain, ice, temperature changes) and chemical impurities in the outside air.

Therefore, along with good electrical conductivity, the wires must have sufficient mechanical strength and withstand well the effects of atmospheric phenomena and chemical impurities. In addition, their operation must be associated with the lowest costs while guaranteeing uninterrupted power supply.

The different operating conditions of overhead power lines determine the need for different conductor designs.

The main constructions are:

1) single-wire conductors made of one metal,

2) multi-wire single metal conductor,

3) stranded conductors of two metals,

4) hollow wires,

5) bimetallic conductors.

Due to the greater mechanical strength and flexibility compared to single-core conductors of the same cross-section, stranded conductors have gained widespread use.

Hollow or hollow conductors are used for power lines with a voltage of 220 kV and above, because due to their large diameters compared to multi-core conductors, they can reduce or even avoid corona losses.

Solid wires, as the name suggests, are made of a single wire.

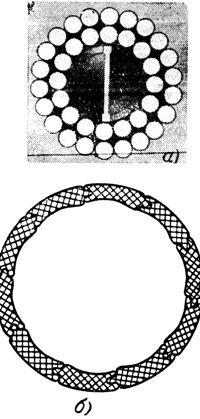

Single metal wires consist of several twisted wires (Fig. 1). Conductors have one central conductor around which successive layers (rows) of conductors are made. Each subsequent layer has 6 more wires than the previous one. With one wire in the center, there are 6 wires in the first twist, in the second - 12, in the third - 18. Therefore, with one twist, the wire is twisted from 7, with two twists - from 19, and in three twists - from 37 wires.

The twisting of adjacent threads is done in different directions, which provides a more round shape and allows you to get a wire that is more resistant to unwinding.

Stranded wires of other strands are used in special cases.

Rice. 1. Multi-wire conductors made of one metal: a-7-wire, b-19-wire.

The temporary resistance of stranded wires is about 90% of the sum of the temporary resistances of the individual wires. The reduction of the temporary resistance of the conductor is generally due to the uneven distribution of the force acting along the conductor between the conductors of the conductor.

Advantages of tensioned wires

Stranded wires have a number of significant advantages over single-wire wires:

1.Multi-core wires are more flexible than single-core wires of the same cross-section, which guarantees their greater safety and ease of installation.

1.Multi-core wires are more flexible than single-core wires of the same cross-section, which guarantees their greater safety and ease of installation.

Under the influence of the wind, the conductors of overhead lines constantly sway and sometimes vibrate, which causes additional mechanical stresses and metal fatigue. In this case, single-wire conductors are destroyed much faster than multi-wire ones.

2. High maximum strength of the material can be achieved only for wires with relatively small diameters. Single-wire conductors with cross-sections of 25, 35 mm2 and more would reduce the final resistance.

In stranded conductors, there cannot be as great a weakening of the wire strength caused by manufacturing defects as in single stranded conductors.

The stated advantages of multi-core wires led to the fact that only wires with small cross-sections were made with single-core wires. In the construction of aerial networks, in most cases multi-core wires are used. Aluminum overhead line conductors are always made with stranded conductors. Single-wire conductors of this metal do not have the necessary mechanical strength and do not ensure the reliability of the power supply to consumers.

Steel-aluminum conductors of overhead power lines

The desire to increase the mechanical strength of aluminum wires led to the production of aluminum wires with steel cores, the so-called steel-aluminum.

Steel-aluminum wires appeared in the practice of power transmission due to the desire to create a wire with high mechanical strength and sufficient electrical conductivity.The advantages of steel-aluminum conductors compared to equivalent conductive copper conductors are significantly lower weight and a significantly larger outside diameter of the wire. Due to the increase in diameter, the voltage at which the corona of the conductor appears, the result is a reduction in corona losses.

The core of the wire is made of one or more twisted galvanized steel wires with a temporary resistance of about 120 kg / mm2. Aluminum conductors covering the core with one, two or three layers are the current-carrying part of the conductor.

In the electrical calculations of steel-aluminum wires, the electrical conductivity of the steel part of the wire is not taken into account, since it is relatively small compared to the conductivity of the aluminum part of the wire.

Mechanical stress (wire stress) is experienced by steel and aluminum. In steel-aluminum conductors with a ratio of aluminum cross-section to steel cross-section of about 5-6, the aluminum conductors take 50-60% of the total stress on the conductor, the rest being the steel core.

Steel-aluminum wires are mainly used in the construction of regional networks from 35 to 330 square meters.

The resistance of steel-aluminum conductors to chemical reagents in the air is the same as that of aluminum and steel separately. It is impossible to lay steel-aluminum conductors near the seas: there is rapid destruction of aluminum conductors adjacent to the steel core under the action of electrolytic corrosion.

If it is necessary to combine low active resistance of a wire with very high mechanical strength, steel-bronze and steel-aluminum wires are used.

The most common steel-aluminum conductors of the AC brand, with a ratio of aluminum to steel cross-sections of about 5.5-6.

Aldry wires have a slightly lower electrical conductivity than aluminum, but almost 2 times higher mechanical strength. Aldry is an aluminum alloy with small amounts of magnesium and silicon dioxide. The low specific weight of alder and its high mechanical strength allow long distances.

Hollow wires

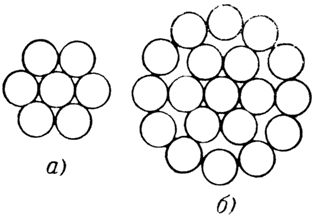

Hollow wire constructions are shown in Fig. 2. In the first of them (Fig. 2, a), round copper wires are superimposed on the spiral core. Depending on the cross-section of the wire, 1-3 wire assets are made. Another type of hollow wire (Fig. 2.6) is made of shaped wires connected with a special lock. This type of hollow wire is more rational.

Lines of voltage 220 kv and above, when made with steel-aluminum conductors, require less construction and operating costs than lines with hollow copper conductors.

Rice. 2. Hollow wires: a — with a screw core of round wires, b — of shaped wires with a lock.

Bimetallic wires

The desire to combine the high conductivity of copper with the high mechanical strength of steel led to the creation of bimetallic conductors. The steel wire is covered with a layer of copper, the metals are joined by welding. The cross-sectional ratio of copper and steel can vary widely, which makes it possible to obtain wires with characteristics close to those of copper or steel wires.

Brands of modern bare wires and their design:

-

A — wire twisted from aluminum wires,

-

AKP — wire of class A, but the interwire space of the entire wire, except for the outer surface, is filled with neutral grease with increased heat resistance,

-

AC — wire consisting of a steel core and aluminum wires,

-

ASKS — AC brand wire, but the interwire space of the steel core, including its outer surface, is filled with neutral grease with increased heat resistance,

-

ASKP — wire of AC brand, but the interwire space of the entire wire, except for the outer surface, is filled with neutral grease with increased heat resistance,

-

ASK — AC brand conductor, but the steel core is insulated with two strips of polyethylene terephthalate film. The multi-wire steel core under polyethylene terephthalate sheets must be coated with a neutral grease with increased heat resistance,

-

AN-wire twisted from ABE brand non-heat treated aluminum alloy conductors,

-

АЖ — wire twisted from heat-treated aluminum alloy conductors of the ABE brand.