What are cable products, definition and classification

All cable products can be reduced to the following main types:

-

bare wires;

-

insulated wires and cables of various types;

-

cables of different types.

Bare wires have only one single structural part — a solid metal core or a core twisted from individual wires. Insulated wires have, in addition to the current-carrying wire, a layer of insulation on the wire and light-shielding covers, for example braid. A cable is characterized by the presence of two or more flexible insulated conductors twisted together in a common sheath.

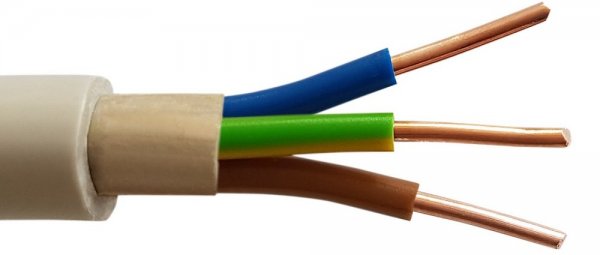

Electric cable characterized by three structural elements:

-

conductive core (one or more);

-

insulating layer;

-

protective shells and covers.

The purpose of the cable is the transmission and distribution of electrical energy.

The origin of the words "cable" and "conductor"

In the 13th century, French sailors called ship ropes or anchor ropes «Kabel», the English called them »kabel», and this word entered the German language at the same time as »Kabel«.

Since the technology of laying underwater cable telegraph lines and transatlantic telegraph communications is connected to ships (laying cables) as well as to drums similar to those used for ship ropes and anchor cables, these telegraph lines are called cables.

Soon the British made a verb out of a noun if it was a question of transmitting a telegram abroad by cable — "to sable «(transmit by cable),» kabeIn" (same in German) — an actual 19th-century word formation.

The terms "cable" and "cabling" first appeared in marine jargon. But soon the term «cable» became a general name for an insulated conductive line.

The word "tel" also has its own history, the origin of which should be sought from navigators, pilots (in ancient Greek, "an accompanying person" who guides ships through difficult fairways near ports).

The concept "to conduct" was formed from the word "escort", giving it the coloring of a "protected" or "insured" escort. In this case, the technical understanding of the term "wire" is present, as it refers to an insulated, shielded conductor.

Classification of cables

All cables can be divided into two groups according to the transmitted power:

-

power cablescharacterized by high transmitted power;

-

communication cables and signal cablesis characterized by very low transmission power.

The structures, materials used to make cables, and the manufacturing process are at the heart of cable technology.

Improving the quality of cable products, the economical use of metals and insulating materials used in the production of cables, the introduction of substitutes for scarce raw materials along with the expansion of the range of cable products — these are the main directions in which modern cable technology is developing.

The calculation of the main characteristics of the cable (electrical, thermal and mechanical) forms the basis of the theory of the cable, which allows to predict the behavior of the cable in service and the most economical choice of the design, the size of the main parts and the way of operation.

The main structural elements of an electric cable

1. Conductive wires, one or more, of various sizes and shapes

The purpose of the core is the direction of the flow of electrical energy in the cable, and the size of the cross section of the core determines the amount of losses in the heating cores from the current passing through them. In order to achieve greater flexibility of the cord, if necessary, they are made not from one wire, but from several twisted together.

2. A layer of insulating material (insulation) separating the conductors from each other and from the metal outer sheath, if any

The purpose of the insulating layer is to counteract the electric field forces between the conductors and the cable sheath that tend to create leakage current (in communication cables) and discharge (fault) in high voltage cables. Cable insulation must always be flexible enough to allow bending of the cable during manufacture and during installation.

The insulation of power cables operating under high voltage must first of all have high electrical strength, which ensures the reliability of the cable in operation. However, high dielectric strength is not always required of the cable insulation.

For example, communication cables usually operate at low voltage and here leakage losses are critical, therefore insulation materials with the lowest possible leakage, i.e. with high insulation resistance and low value of dielectric loss tangent, are used to insulate communication cables.

3. Protective covers and covers that protect the insulation layer of the cable from environmental influences and mechanical damage

This should also include various types of anti-corrosion coatings, the purpose of which is to protect cable sheaths and covers from environmental corrosion. Different types of sheaths (lead, rubber, etc.) differ in their mechanical strength, corrosion resistance, and mainly in moisture resistance, since most cable insulation materials significantly deteriorate their insulation properties when wet.

Sergey Antonov, painting «Pulling the cable» 1968.

Materials used in the manufacture of wires, cables and cables

A distinction is made between materials used for the production of the conductive core, the insulating layer and the outer covers with protective sheaths.

But the following classification is more convenient:

-

metals;

-

fibrous materials;

-

polymeric materials;

-

liquid insulating materials;

-

solid insulating materials based on natural and synthetic resins;

-

varnishes, compounds and bitumen.

In the production of cables, metals are used: copper and its alloys, aluminum, lead and steel.Copper and aluminum are mainly used for the production of conductive wires of wires, cables and cables, while lead and steel are used for the production of protective casings and armor.

The suitability of these metals for the manufacture of wires and cables is mainly determined by the electrical (electrical resistance) and mechanical (tensile and elongation) characteristics.

Cross section of 400 kV XLPE insulated power cable. Such a cable is used in a 380 kV overhead transmission line in Berlin. Cable section — 1600 mm2. The 34-kilometer line was built in 2000.

Classification and labeling of power cables

A cable that can be used for buried ground

Heavy copper cables

Cable for oil pump installations that has copper conductors, heat resistant block copolymer insulation and a fluoroplastic sheath for each of the three conducting wires. According to the new cable production technology, fluoroplastic is applied to insulated conductive wires by extrusion: after processing the material on special equipment, the resulting polymer mass passes through the forming tool and "wraps" the wires.

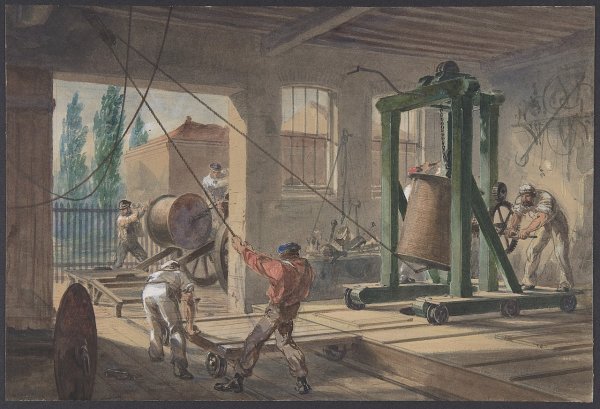

From the history of cable technology

The history of cable technology begins with the first attempts to produce insulated wire, the need for which arose around 1753 in connection with the study of atmospheric electricity.

The first period in the development of cable technology lasted until about the middle of the 19th century and was characterized by attempts to make insulated wire and cable using glass tubes, sealing wax and other materials at hand.

An important role in this period of cable technology development was played by P.L.Schilling, the inventor of the electric mine. The merit of PL Schilling is that he was the first to use the material (rubber) for cable insulation, which was introduced into the production of wires and cables 60 years later.

From the middle of the 19th century, the production of underwater communication cables insulated with gutta-percha (a resin very similar in composition to natural rubber) began in England and Germany.

More details on the use of natural materials in cable technology:

The use of rubber and rubber materials in electrical engineering

Covering the cord with gutta-percha. Greenwich, 1865-66. Painting by R. C. Dudley

Cable products (cables, wires, cables) used in electricity are classified according to the following criteria:

- by the nature of the isolation,

- according to the material of the conducting veins,

- by the shape and design of the conductive core,

- by the type of protective shells,

- by production and construction characteristics,

- by appointment

- High current cable products are also divided by voltage.

According to the production and design characteristics, all types of cable products are divided according to the number, section or diameter of the conducting cores, according to the flexibility of the core, according to the twisting system, according to the external shape (round, triangular, etc.), according to the type of external covers and others.

Useful information: How do wires differ from cables?