Protective sheaths and cable sheaths: purpose, materials, types, anti-corrosion, armored

Appointment of protective shells and covers

Protective covers serve to protect the insulation layer wire or cable from the influence of the environment, but mainly from the influence of moisture. The less moisture-resistant the insulation of the cable or wire, the more perfect the sheath must be applied.

The physical operating conditions of the cable also influence the choice of sheath material, for example, if increased flexibility of the cable is required, then a flexible sheath should be used.

Materials used for containment are few, namely lead, aluminum, rubber, plastics, and combinations thereof.

Protective covers of wires and cables serve to protect the conductor from mechanical stress during laying or during operation, as well as to protect cable sheaths from corrosion, therefore anti-corrosion coatings are sometimes distinguished from the group of protective covers.

As an anti-corrosion coating, cable paper is most often used, applied from a layer with simultaneous watering with bitumen compositions of appropriate viscosity.

Protective sheaths consist of cotton or cable yarns applied in the form of a braid or braid on the insulating layer or protective sheath of the cable or a braid on the insulating layer or protective sheath of the cable or conductor.

Covering protective casings with plastics is widespread to protect them from corrosion and mechanical damage.

As an anti-corrosion coating, cable paper is most often used, applied from a layer with simultaneous watering with bitumen compositions of appropriate viscosity.

A braid of thin steel wires is often used for mechanical protection of flexible wires and cables.

In a number of designs, braids made of cotton and other yarns are covered with special varnishes (coating varnishes) that protect the wire from the influence of the environment, from the action of ozone and increase the resistance of the wire to moisture and gasoline.

Composite coverings of plastics, metal foil, and cloth or coated paper are also used, and in some cases can replace the lead sheath (especially for cables used for indoor and temporary installations).

Retaining materials

Lead is the main material from which the most reliable vests are made. The main advantage of the lead sheath over all other sheaths and coatings is its complete moisture resistance, sufficient flexibility and the ability to quickly and cheaply apply to the cable using a lead press.

However, lead has many disadvantages: high specific gravity, low mechanical strength, insufficient resistance to mechanical and electrochemical corrosion.

All this, taking into account the limited and natural reserves of lead, makes it necessary to improve the quality of lead sheaths, to introduce substitutes and to design new types of cable products without lead sheaths.

Lead not lower than grade C-3, with a lead content of 99.86%, is used for sinking cable sheaths.

The mechanical strength of the lead shell is largely determined by its structure. The fine-porous structure obtained as a result of the production of the shell from lead grades C-2 and C-3 with rapid and intensive cooling of the extruded shell is the most mechanically strong and stable .

With a medium and coarse grain structure, low quality dots are obtained. From such shells, even under normal production conditions, lead crystals grow, which then shift relative to each other along the cleavage planes, and this leads to premature destruction of the shell.

Very pure lead is very prone to crystal formation and growth even at room temperature, making it unsuitable for the production of lead sheaths.

A measure to combat lead crystallization is, in addition to cooling after lead coating, the addition of tin, antimony, calcium, tellurium, copper and other metals to the lead.

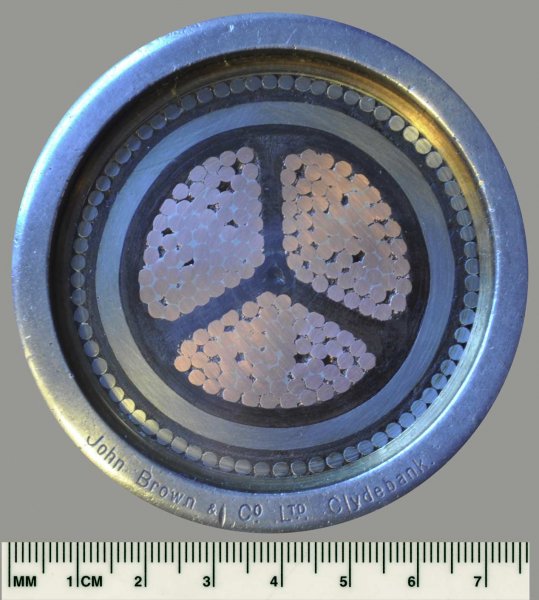

Battlecruiser cable, built for the Royal Navy of Great Britain, commissioned in 1920. Three conductors, lead sheathed, in armour.

The best additive is tin, which, when contained in lead in an amount of 1-3% by weight, provides a stable fine-grained structure. However, tin is very scarce and is currently being replaced in cable sheaths by other metals.

The introduction of antimony into lead in an amount of 0.6 to 0.8% favorably affects the structure of the lead shell and increases the mechanical strength, lowering somewhat the elasticity, that is, the ability of the lead shell to bend. An addition of tellurium in an amount of about 0.05% gives good results. The so-called copper lead, which is lead with an admixture of copper — in an amount of about 0.05% — also became widespread.

In addition to double alloys, there are ternary alloys of lead with cadmium, tin (0.15%), antimony and other metals. These alloys are less convenient to manufacture and their test results are close to those of some binary alloys and copper-lead.

Aluminum can also be used to make cable jackets. For this purpose, both technical and high-purity aluminum (with aluminum content 99.5 and 99.99%) are used, the mechanical characteristics of which are better than those of lead and lead alloys.

The strength of the aluminum shell is at least 2-3 times higher than the strength of the lead. The recrystallization temperature of aluminum, as well as its resistance to vibration, are significantly higher than those of lead.

The specific gravity of aluminum is 2.7 and that of lead is 11.4, therefore, replacing the lead sheath with aluminum can result in a large reduction in the weight of the cable and an increase in the mechanical strength of the sheath, which will make it possible in some cases to refuse the reinforcement of the cable with steel strips.

The main disadvantage of aluminum is its insufficient corrosion resistance… The process of applying the sheath to the cable is significantly complicated by the high melting point of aluminum (657 ° C) and the increased pressure during pressing, which reaches three times the pressure when pushing out the lead sheath.

Aluminum sheathing can be applied not only by crimping, but also by a cold method, in which insulated wires and cables are drawn into aluminum tubes previously made by extrusion, followed by sheathing by drawing or rolling. This method allows commercial grade aluminum to be used.

The method of cold welding of an aluminum sheath is quite common, which consists in the fact that the edges of an aluminum strip applied longitudinally to the cable pass between rollers, with the help of which a high specific pressure is created on the aluminum, sufficient for its cold welding.

Currently, plastics are successfully used to produce protective sheaths for wires and cables instead of lead. When increased cable flexibility is required, vulcanized rubber and plastic sheaths are most suitable.

Vulcanized rubber hose covers are the most widely used in cable manufacturing. on natural or synthetic rubbers and from thermoplastic materials such as PVC, polyethylene.

The mechanical strength of such shells is quite high (tear strength in the range from 1.0 to 2.0 kg / mm2, elongation from 100 to 300%).

The main drawback is the noticeable moisture permeability, which is understood as a value characterizing the ability of the material to pass water vapor under the influence of a pressure difference on both sides of the material layer.

Vulcanized rubber on natural rubber can work for a long time in the temperature range from -60 to + 65 ° C. For most plastics, these limits are much narrower, especially for temperatures below zero degrees.

There are silicone rubbers, new rubber materials that are silicon silicon polymers. These are high molecular substances, in the basis of which the structure of silicon atoms is combined with carbon atoms.

The sheath made of thermoplastic materials, compared to the lead sheath of the cables, can significantly reduce the weight of the cable and increase the corrosion resistance of the sheath and mechanical strength (see also — Wires and cables with rubber insulation).

Destruction of the lead sheath

The mechanical strength of the lead sheath is necessary to ensure sufficient protection of the insulating layer from the environment surrounding the cable. This property (mechanical strength) must be maintained for a long time during the operation of the cable for several decades and not change over time under the influence of mechanical (vibration) and chemical (corrosion) causes.

The mechanical properties of lead sheaths and their stability under the influence of various causes depend mainly on the structure of the sheath and its changes under the influence of heat and vibration.

Cables with a lead sheath with a coarse-grained structure often do not withstand long-term transport, even by rail (especially in summer).

Under the influence of shaking and increased temperature, lead crystals begin to grow, a network of small cracks appears on the shell, which deepen more and more and finally lead to the destruction of the shell.The lead sheaths of cables laid on bridges are particularly susceptible to vibration damage.

There have been cases when lead cables, sent in the summer by rail for several thousand kilometers, arrived at their destination with a completely destroyed shell.

Such cases most often occur on lead sheaths made of pure lead. Additions of tin, antimony, tellurium and some other metals give a stable fine grain structure and are therefore used in the production of lead cable sheaths.

When the leakage current leaves the lead sheath of a cable laid in moist calcareous soil containing C0 ion3lead carbonate PbC03 at the exit point where the lead sheath is subsequently destroyed.

Electrochemical corrosion of lead can lead to complete destruction of the lead sheath in one to two years, since a current of 1A per year can carry about 25 kg of lead or 9 kg of iron, and therefore with an average leakage current of 0.005 A in one year destroys about 170 g of lead or about 41.0 g of iron.

A radical measure fight against electrochemical corrosion is the so-called cathodic protection, based on the fact that the protected metal is given a negative potential with respect to the surrounding structures, which makes this metal immune to almost all types of soil corrosion.

The minimum electronegative potential at which all types of corrosion cease is 0.85 V for steel pipes and 0.55 V for lead sheaths of electrical cables.

In a number of cases, the coating of the lead sheath provides good protection against electro-corrosion with a protective cover consisting of a layer of semi-conducting bitumen, two semi-conducting rubber strips and a fixing white tape. In this case, a kind of electronic filter is obtained, which passes the electric current leaving the sheath, and separates the lead from the direct effect of the received in ion electrolysis.

Mechanical forces in the cable sheath

Mechanical forces in the cable sheath arise as a result of the flow of the impregnating mixture in a vertically suspended power cables, as well as due to thermal expansion of the impregnating mixture when the cable is heated. In modern high voltage cables filled with oil and gas the lead sheath must withstand considerable internal pressure.

As the impregnating mixture is heated, the pressure in the cable increases to a value corresponding to the hydrostatic pressure. The better the impregnation of the insulating layer, the greater the pressure is obtained in the cable during heating, since the volume of gas inclusions decreases with the improvement of the impregnation of the cable.

Under the influence of the pressure acting on the inner side of the sheath, the latter tends to expand, and if the limit of elastic deformation of the lead is exceeded, then a permanent deformation will occur, which weakens the lead sheath and reduces the operational properties of the cable.

Repeated heating and cooling cycles of the cable resulting in permanent deformations in the lead can cause the lead sheath to rupture.

Since lead without additives at room temperature has almost no elastic limit, the appearance of such permanent deformations in the lead sheath of the working cable will undoubtedly lead to a violation of its mechanical strength.

The presence of additives in the lead increases the mechanical properties and in particular the elastic limit of the sheath, therefore, for cables exposed to pressure from the inside, it is mandatory to use alloyed lead or special double and triple alloys.

The reduction of the mechanical properties of the lead shell over time determines its life span. From this point of view, the concept of the «shell life curve» arises, which means the relationship between the tensile strength in the shell and the duration of its action until the shell ruptures .

In cases where reinforcement of the lead sheath of the cable is required, for example in gas-filled cables or intended for laying on a steeply inclined route, the application of a strip armor of two thin brass or steel strips increases the mechanical strength of the sheath and makes it suitable for high pressure, developing in the cable.

Armored cables

The lead sheath does not provide sufficient protection against mechanical influences, for example accidental impacts on the cable during installation, and in particular against tensile forces occurring both during the laying of the cable and during its operation.

In cables for vertical installation, especially in river and sea, it is necessary to protect the lead sheath from tensile forces, because without such protection, the lead sheath will be torn or damaged over time.

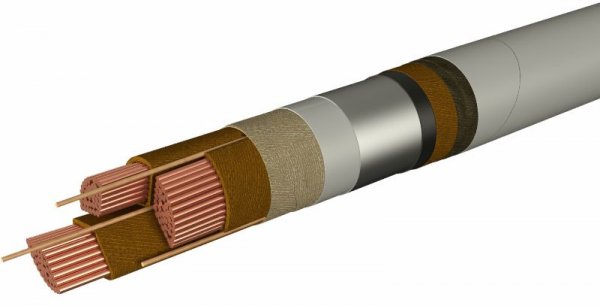

There are two main types of armor: tape, which protects the cable primarily from accidental mechanical influences during laying, and wire — from tensile forces.

The strip armor consists of two steel strips layered on a backing of fibrous materials so that the gaps between the turns of one strip overlap the turns of the other strip. The gaps between the edges of the turns of one strip are equal to about a third of the width of the strip, and the overlap of the turns of one strip with turns, the other, should be at least a quarter of the width of the strip armored strip.

Such an implementation of the cable armor allows to protect the lead sheath from hitting with a shovel when laying the cable and other not too strong mechanical influences, and at the same time preserves the flexibility necessary for laying the cable, which is obtained by moving «bends of the tape armor relative to each other.

The disadvantage of the tape armor is the possibility of displacement of the bends of the armor tape when the cable is dragged along the ground during laying. Such armor is mainly used for armoring underground cables, as well as cables laid indoors in cable tunnels and on the walls of buildings.

The steel tape used in the cable industry should have a tensile strength of 30 to 42 kg/mm2, because the tape with high tensile strength is very springy and does not sit well on the cable during booking. Elongation at break 20 - 36% is required (with an estimated sample length of 100 mm).

For armoring power cables, a steel tape with a thickness of 0.3, 0.5 and 0.8 mm and a width of 15, 20, 25, 30, 35, 45 and 60 mm is used, depending on the diameter of the cable. The tape should be delivered in circles with a diameter of about 500 - 700 mm.

Armor wire is used round and segmented (flat). Round wire is used to armor cables that must withstand significant tensile forces during installation or operation (eg submarine cables). Segmented wire is used for cables laid in mines and on steep inclined routes.

To protect against corrosion, the wire used for armoring must be coated with a thick, continuous layer of zinc.

In reservation, a wire armor, similar to tape, is applied to the cable on a cushion, which may consist of a layer of cable yarn pre-impregnated with an anti-rot compound, covered with a layer of bituminous mixture on top.

For wire armour, the direction of twist is taken in the direction opposite to the direction of full twist of the cable cores.

To protect the armor from corrosion (corrosion), it is covered with a bituminous compound and a layer of pre-impregnated cable yarn covered on top with the same compound. The outer layer of the cable yarn is designed not only to protect the armored tape or the armored wire from corrosion, but also serves for fastening, that is, it does not allow the armored tapes to move and holds the armored wires in a twine.

Cables intended for indoor installation must not have a layer of impregnated cable yarn over the armored coating for fire safety reasons. Such cables, for example cables of the SBG brand, must be armored with varnished armor tape.

The reservation process consists of applying protective covers and armor.Lead cable should be applied in sequence: a layer of bituminous composition twisted with two strips of cable paper (anti-corrosion coating), a layer of compound, cable yarn or impregnated sulfate paper (cushion under the armor), a layer of bituminous composition, an armor made of two steel strips or steel wires, a layer of bituminous composition, cable yarn (outer cover), a layer of bituminous composition and chalk solution.