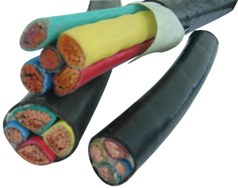

Types of cable and wire insulation

In the production of cables, different materials are used to insulate wire elements. The main condition is insulation of cables and wires — it should not conduct current, which is why materials are traditionally used here: rubber, PVC, polyethylene, fluoroplastic or paper. In some cases, they are also used as insulating materials: magnesium oxide, varnish, silk or polystyrene.

In the production of cables, different materials are used to insulate wire elements. The main condition is insulation of cables and wires — it should not conduct current, which is why materials are traditionally used here: rubber, PVC, polyethylene, fluoroplastic or paper. In some cases, they are also used as insulating materials: magnesium oxide, varnish, silk or polystyrene.

Type of cable insulation selected based on design characteristics of the cable and the mains voltage at which it will operate:

- for sheathed cable products with a direct voltage of not more than 700 volts and a rated alternating current of not more than 220 volts for single-phase networks (380 volts in the case of three-phase);

- for unsheathed cables with constant voltage indicators not exceeding 700 volts and rated alternating current up to 220 volts (380 volts for three-phase networks);

- for sheathed and unsheathed cables with indicators for direct current not more than 700-1000 volts and alternating current from 220 to 400 volts (for three-phase networks for 380 and single-phase for 220 volts);

- for direct voltage cables up to 3600 volts and alternating current indicators from 400 to 1800 volts;

- for cables operating under conditions of direct voltage 1000 — 6000 volts with alternating current 400 — 1800 volts.

Rubber-based insulating materials used in the production of cables can be of both natural and synthetic origin. An important advantage of rubber insulation of wiring and cables is sufficiently high flexibility, which makes it possible to install networks in any conditions. But over time, the rubber insulation braid loses its protective properties and undergoes changes in the chemical properties of the material, which negatively affects the reliability of the insulation layer.

Rubber cable KG (rubber insulation based on natural and butadiene rubbers)

HDPE or LDPE insulation, it is highly resistant to chemical or other aggressive environments. Vulcanized polyethylene is not afraid of temperature extremes, but conventional types of polyethylene insulation are unstable when heated. Therefore, they are not recommended for use in high temperature environments.

Power cable with XLPE insulation

Insulation materials based on PVC are derivatives of polymers, with all their advantages and disadvantages. PVC insulation is cheaper for the manufacturer than any other type of insulation material. But with the addition of plasticizers, the braid of the wire or cable loses a little of its protective properties and the chemical resistance of the material decreases. At the same time, PVC-based insulation is highly elastic, and by choosing the right additives, you can give it additional properties: heat resistance and preservation of elasticity at low temperatures.

Power cables with PVC insulation

Insulation with a paper backing, with an abundance of modern materials, is used quite limited today.The permissible voltage for this type of wiring is no more than 35 kV. If paper insulation used in the production of power cables — it is necessary to use a paper base impregnated with a special composition that includes wax, oil and rosin. As a result, the paper acquires unusual characteristics for it. High voltage networks are insulated with a material created from a multi-layered cellulose base. Among the obvious disadvantages of such insulation is the instability of paper to any external influences.

Power cable with paper insulation

PTFE insulating layer of wires and cables — one of the most reliable. However, the use of this material requires some effort, since the PTFE in the tapes is wound on cable cores and then baked under the influence of high temperatures. The resulting coating is highly resistant to any external influences: it is not easy to damage it mechanically, chemically or otherwise.

See on the subject: XLPE insulated cables: device, design, advantages, applications