Tip crimping pliers

For crimping insulated and non-insulated terminals to fix them on the ends of wires of different cross-sections, manual crimping pliers called crimpers are used. Crimpers belong to the professional tools for electrical installation and are produced by many companies — manufacturers of hand tools.

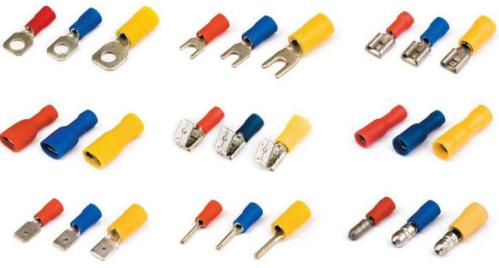

Crimping pliers can be used to crimp various types of terminals: ring, fork, pin, plug and flat connectors, coupling sleeves and other types of terminals.

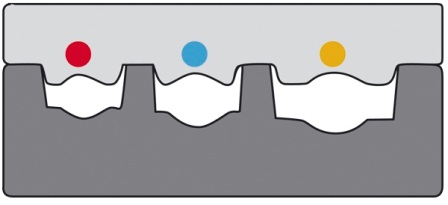

The jaws of the pliers are called a matrix, on it there are specially shaped recesses for different diameters of crimped wires, flexible multi-core and solid single-core and, respectively, for different ears.

Insulated lugs are suitable for stranded wires, non-insulated lugs for solid solid.

Tips as such are a convenient means of reliably connecting sockets, circuit breakers, RCDs, lamps, switches, chandeliers, counters and many other devices.

For crimping veins with a significant cross-section, more than 16 square millimeters, hydraulic presses are used, but manual crimping pliers and crimping tools are also suitable for the needs of a professional electrical installation.

Crimping pliers are different. There are specialized crimpers, for example, for crimping only 4P4C and 4P2C telephone connectors, as well as multi-functional ones that combine, for example, a stripper — a tool for removing insulation. There are crimpers for optical connectors, for D-sub connectors, etc.

A typical crimping tool has comfortable plastic handles and a steel body and jaws. Such a device allows one hand to bend the tip.

The ratchet clips are especially handy, blocking the release until the tip is completely bent to prevent it from being pressurized. If crimping needs to be interrupted, for example due to a wire or ferrule diameter error, the ratchet can be unlocked manually.

The clips, which are often located on the jaws, are marked with different colors, for example, a press for a wire with a cross section of 0.25 to 1.5 sq. Mm is marked in red, a crimp for a wire with a cross section of 0.25 to 1 .5 sq. Mm, blue — from 1.5 to 2.5 sq. Mm, yellow — from 4 to 6 sq. Mm. Mmm. This is necessary so that you do not get confused and do not mistake the diameter of the wire and the tip. By the way, the insulated ears themselves also have colored cuffs with corresponding colors.

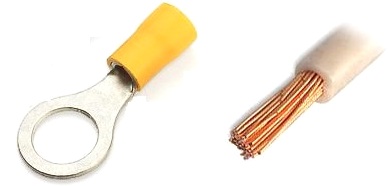

The crimping process is quite easy. For example, you need to bend the wire PUGV 1×4.0 sq.mm. To do this, take the necessary tip, for example, we need an annular one, and we chose NKI 6.0-4, which is suitable for wires with a cross section of 4 to 6 square mm.

First, the insulation is removed from the wire for the length of the pipe part of the tip to obtain the contact part, the wires of the wire are twisted a little, the tip is placed so that the wire protrudes slightly (by about 1 mm) beyond the cuff, and the insulation rests against the metal.

The tip is installed in the die of crimping pliers, in our case - in yellow and crimped, holding the wire. There is an indentation along the tip profile in the wire. The strength of the resulting crimp is then checked.

With the help of crimping pliers, you can crimp various connectors, crimp various wires, select the necessary terminals and tips.

Among the huge assortment of crimping tools on the market today, every professional installer can easily choose the tool for his profile. It can be only a crimp or crimping press, multi-functional or only for one type of connectors, for example RJ45.