Why you need a starter and a choke in the circuits for turning on fluorescent lamps

The main elements of the circuit for turning on a fluorescent lamp with an electromagnetic ballast are a choke and a starter. The starter is a miniature neon lamp with one or both electrodes made of bimetal. When a glow discharge occurs in the starter, the bimetallic electrode heats up and then bends, shorting the second electrode.

The main elements of the circuit for turning on a fluorescent lamp with an electromagnetic ballast are a choke and a starter. The starter is a miniature neon lamp with one or both electrodes made of bimetal. When a glow discharge occurs in the starter, the bimetallic electrode heats up and then bends, shorting the second electrode.

Once the voltage is applied to the circuit, the current does not flow through the fluorescent lamp because the gas gap in the lamp is an insulator and it needs a voltage that exceeds the supply voltage to break it. Therefore, only the starter lamp lights up, the ignition voltage of which is lower than the mains voltage. A current of 20 — 50 mA flows through the choke, the electrodes of the fluorescent lamp and the neon starter lamp.

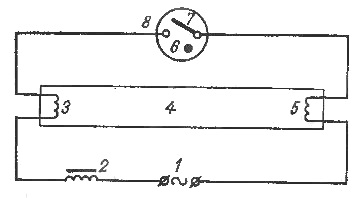

Boot device:

Boot device:

The starter consists of a glass cylinder filled with an inert gas. Fixed metallic and bimetallic electrodes are soldered into the cylinder, with wires passing through the caps.The container is enclosed in a metal or plastic casing with an opening at the top.

Scheme of a starter device with a glow discharge: 1 — terminals, 2 — movable metal electrode, 3 — glass cylinder, 4 — bimetallic electrode, 6 — base

Starters for connecting fluorescent lamps to the network are available for voltages of 110 and 220 V.

Under the influence of the current, the electrodes of the starter are heated and closed. After a short circuit, a current flows 1.5 times the rated current of the lamp. The magnitude of this current is limited mainly by the resistance of the choke, since the electrodes of the starter are closed, and the electrodes of the lamps have little resistance.

Elements of the circuit with a choke and a starter: 1 — clamps for mains voltage; 2 — throttle; 3, 5 — lamp cathodes, 4 — tube, 6, 7 — starting electrodes, 8 — starter.

In 1-2 seconds, the electrodes of the lamp are heated to 800 — 900 ° C, as a result of which the emission of electrons increases and the breakdown of the gas gap is facilitated. The electrodes of the starter are cooled because there is no discharge in it.

When the starter cools, the electrodes return to their original state and break the circuit. The moment the circuit breaks from the starter, an e is generated. etc. c. self-inductance in the choke, the value of which is proportional to the inductance of the choke and the rate of change of the current at the moment of breaking the circuit. Formed by e. etc. with self-induction, an increased voltage (700 — 1000 V) is applied by pulse to the lamp prepared for ignition (the electrodes are heated). A fault occurs and the lamp comes on.

Approximately half of the mains voltage is supplied to the starter, which is connected in parallel with the lamp.This value is not enough to break a neon bulb, so it will no longer light up. The entire ignition period lasts less than 10 seconds.

Examining the process of lighting the lamp makes it possible to clarify the purpose of the main elements of the circuit.

The starter has two important functions:

1) short circuit in order to heat the electrodes of the lamp with an increased current and facilitate ignition,

2) interrupts the electrical circuit after heating the lamp electrodes and thus causes an increased voltage pulse, providing a breakdown of the gas gap.

The choke has three functions:

1) limits the current when the starter electrodes are closed,

2) generate a voltage pulse for the lamp failure due to e.etc. c. self-induction at the moment of opening the starter electrodes,

3) stabilizes the combustion of the arc discharge after ignition.

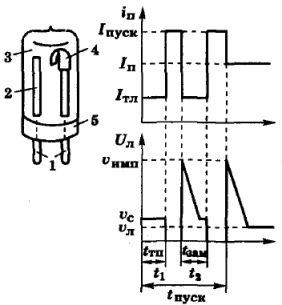

Fluorescent lamp ignition pulse circuit in action: