Prospects for the development of white LED technology

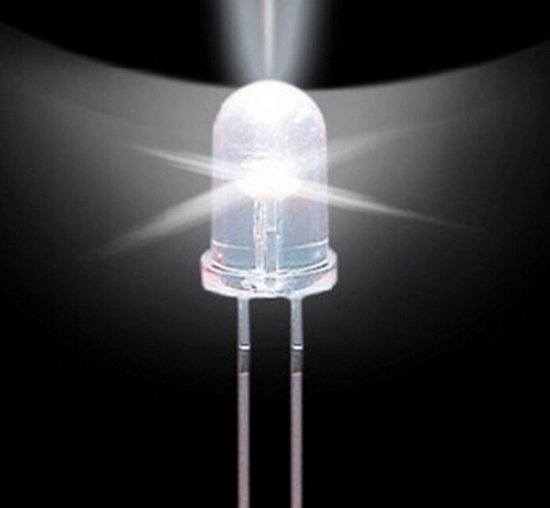

LEDs are the most economical and high-quality light source. It is not for nothing that the technology for the production of white LEDs, which are used continuously for lighting, is constantly in a state of progress. The interest of the lighting industry and the common man in the street has stimulated constant and numerous researches in this area of lighting technology.

We can already say that the prospects for white LEDs are huge. This is because the obvious benefits of saving electricity spent on lighting will continue to attract investors to research these processes, improve technologies and discover newer, more efficient materials for a long time.

If we pay attention to the latest publications by LED manufacturers and developers of materials for their creation, experts in the direction of semiconductor research and semiconductor lighting technologies, we can highlight several directions on the way of development in this field today.

It is known that the conversion factor phosphorus is the main determinant of LED efficiency, moreover, the re-emission spectrum of the phosphor affects the quality of the light produced by the LED. Thus, the search and research of even better and more efficient phosphors is one of the most important directions in the development of LED technology at the moment.

Yttrium aluminum garnet is the most popular phosphor for white LEDs and can achieve efficiencies of just over 95%. Other phosphors, although they give a better quality spectrum of white light, are less efficient than the YAG phosphor. For this reason, numerous studies aim to obtain an even more efficient and durable phosphor, giving the correct spectrum.

Another solution, although still distinguished by its high price, is a multi-crystal LED that gives bright white light with a high-quality spectrum. These are combined multi-component LEDs.

Multi-color semiconductor chip combinations are not the only solution. LEDs that contain several color chips as well as a phosphor component are displayed much more effectively.

Although the efficiency of the method is still low, the approach is nevertheless worthy of attention when quantum dots are used as a converter. In this way, you can create LEDs with high light quality. The technology is called white quantum dot LEDs.

Since the biggest efficiency limit lies directly in the LED chip, increasing the efficiency of the semiconductor emitting material itself can help improve efficiency.

The conclusion is that the most common semiconductor structures do not allow a quantum yield above 50%.The best current quantum efficiency results have been achieved only with red LEDs, which give an efficiency of just over 60%.

Structures grown by gallium nitride epitaxy on a sapphire substrate are not a cheap process. A shift to cheaper semiconductor structures could speed up progress.

Taking other materials as a basis, such as gallium oxide, silicon carbide or pure silicon, will significantly reduce the cost of LED production. Attempts to alloy gallium nitride with different substances are not the only way to reduce costs. Semiconductor materials such as zinc selenide, indium nitride, aluminum nitride, and boron nitride are considered promising.

The possibility of widespread use of phosphor-free LEDs based on the growth of a zinc selenide epitaxial structure on a zinc selenide substrate should not be ruled out. Here, the active region of the semiconductor emits blue light, and the substrate itself (since zinc selenide itself is an effective phosphor) turns out to be a source of yellow light.

If another layer of semiconductor with a bandgap of smaller width is introduced into the structure, it will be able to absorb some quanta with a certain energy and the secondary emission will occur in the region of lower energies. The technology is called LEDs with semiconductor emission converters.