What are the basics of LED lamps

The LED lamp, like any other light bulb, is connected to the socket using a base. This is the basis that provides a solid electrically conductive contact between the source of electrical energy and the user, in this case, between the contacts of the cartridge (connected to the power network) and the assembly with LEDs (located inside the LED lamp) ). It turns out to be a detachable, but at the same time well-conducting electric current, connection through which the lamp is powered.

Lamp holders come in a variety of shapes and sizes and only a lamp with a matching base will fit any lamp holder. Let's see what kind of caps LED lamps have and why they are like that.

The entire variety of caps for LED lamps can be divided into two groups that are fundamentally different in the way they are installed in the lamp holder: contact and threaded caps. Both are available in different sizes. However, we will consider only the most popular of them, because in fact all types of standard sizes inherent in various lighting devices are countless, given the variety of their applications in the modern world flooded with artificial light.

Threaded chucks

Currently, threaded lamp holders are the most common.Such cartridges were used in everyday life with incandescent lamps and compact fluorescent (energy-saving) lamps. A large number of modern LED lamps are suitable for direct replacement of old-style lamps, which is why they have bases designed for threaded sockets.

The main part of threaded cartridges is an insulating base (base) with metal contact parts mounted on it. The contact parts of the cartridge include: a screw sleeve, a central spring contact, a contact bridge and a contact clamp together with clamping screws for connecting the supply wires to them.

All contact parts are made of brass and the spring-loaded center contact is made of phosphor bronze. The outer body of the chuck is made of brass with subsequent nickel plating. The grain is one piece with the bottom of the cartridge, it is fixed firmly and cannot be turned when screwing the bottom. The base (base) of the chuck is made of porcelain or plastic.

When attaching the wire ends to the clamping screws of the metal body chuck, care must be taken that the prepared loop is smaller in diameter than the head of the clamping screw and that the bare ends of the wires cannot come into contact with the body or the bottom of the the cartridge. After cutting the cable with the ring, the rubber insulation should be brought to the ring itself.

E27 base

The most common base LED lamp — classic base E27 — base Edison. In the old days, it was used in absolutely all standard incandescent lamps. This base has not lost its relevance in the era of LED lighting.

It is believed that lamps powered by a mains voltage of 220 volts and with a luminous flux of more than 1200 lm should have exactly such a threaded base — E27 (standard).The number 27 in this case is the diameter of Edison's base in millimeters — 27 millimeters.

E14 base

The Mignon E14 base is the second most popular threaded base used for LED lamps in everyday life. This base is almost twice as narrow as E27; as a rule, miniature bulbs with bulbs in the form of candles, mushrooms, balls are equipped with it.

Such bulbs are installed in various sconces, bedside lamps, decorative lighting fixtures, etc. A few small lamps with E14 bases can be found in wall lamps and chandeliers, such lamps are miniature, pleasant to look at, less powerful than lamps with a base E27, their threads with a diameter of 14 millimeters.

Base / socket GU10

The two-pin GU10 contact base differs from threaded counterparts in the way the lamp equipped with it is fixed in the socket. Here the lamp is not attached to the thread, in fact there is a kind of pin lock fixing the lamp.

The lamp is held in the socket firmly enough that even with vibration and shaking it will not fall out or come off the thread, as can happen with E27 and E14 bases.

MR16 LED ceiling lamps are often equipped with just such a base — GU10. As you've probably already guessed, 10 is the distance in millimeters between the pins on this base.

Socket GU5 / 3

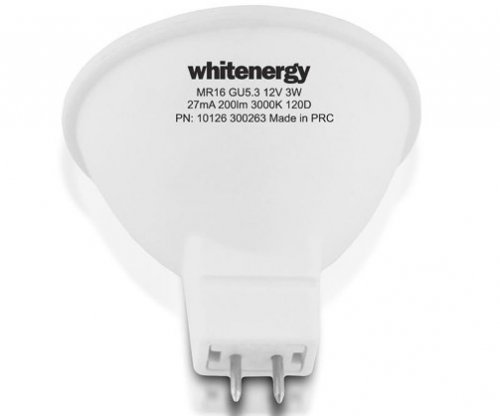

The two-pin GU5 / 3 base differs from the GU10 base that we just discussed above by almost a widow in the smaller distance between its contact pins. It is not by chance that this base is so popular in cases where the LED lamp is powered by low voltage — 12 or 24 volts at direct current.

The same reflective LED ceiling lamps of standard size MR16, but with low voltage - most often equipped with a GU5 / 3 base, with a pin spacing of 5.3 mm.They are often found in decorative lighting systems powered by power supplies.

Socket G13

The offices still have tube-shaped lamps mounted in Armstrong-type ceiling lamps. Gas discharge ancestors are quickly giving way to LED lamps.

These lamps have an end lock in which the G13 base - the base of the pin - is hidden. T-8 and T-10 LED tube lamps are typical LED lamps with G13 caps. The distance between the pins is 13 millimeters.

The most popular bases for LED lamps: