Modern high pressure sodium lamps

High-pressure sodium lamps (HPL) are one of the most efficient light sources and already today have a light efficiency of up to 160 lm / W at powers of 30 — 1000 W, their service life can exceed 25,000 hours. The small size of the light body and the high brightness of high-pressure sodium lamps significantly expand the possibilities of their application in various lighting devices with concentrated light distribution.

Typically, high-pressure sodium lamps operate with an inductive or electronic ballast. High-pressure sodium lamps are ignited using special igniters that emit pulses up to 6 kV. The lighting time of the lamps is usually 3 to 5 minutes.

The advantages of modern high-pressure sodium lamps include a relatively small drop in luminous flux during the service life, which, for example, for lamps with a power of 400 W is 10-20% in 15 thousand hours with a 10-hour burning cycle. For lamps operating more frequently, the drop in luminous flux increases by approximately 25% for each doubling of the cycle.The same relationship applies to calculating the reduction in service life.

It is generally accepted that these lamps are used where economy is more important than accurate color reproduction. Their warm yellow light is quite suitable for lighting parks, shopping centers, roads, and also in some cases for decorative architectural lighting (Moscow is an excellent example of this). The development of these light sources in the last decade has led to a dramatic expansion of the possibilities of their use due to the appearance of new output types, as well as low-power lamps and lamps with improved color rendering.

1. High pressure sodium lamps with improved color rendering

High pressure sodium lamps are currently the most efficient group of light sources. However, standard high-pressure sodium lamps have a number of disadvantages, of which, first of all, it is necessary to note clearly deteriorated color rendering properties, characterized by a low color rendering index (Ra = 25 — 28) and a low color temperature (Ttsv = 2000 — 2200 K).

High pressure sodium lamps are currently the most efficient group of light sources. However, standard high-pressure sodium lamps have a number of disadvantages, of which, first of all, it is necessary to note clearly deteriorated color rendering properties, characterized by a low color rendering index (Ra = 25 — 28) and a low color temperature (Ttsv = 2000 — 2200 K).

The broadened sodium resonance lines cause a golden yellow emission. The color rendering of high-pressure sodium lamps is considered satisfactory for outdoor lighting, but insufficient for indoor lighting.

The improvement in color performance of high-pressure sodium lamps is mainly due to an increase in sodium vapor pressure in the burner as the temperature of the cold zone or the sodium content of the amalgam increases.(amalgam — liquid, semi-liquid or carbide metal with mercury), increasing the diameter of the exhaust pipe, introducing radiating additives, applying phosphors and interference coatings to the outer bulb and feeding the lamps with high-frequency pulsed current. The decrease in luminous flux is compensated by an increase in xenon pressure (ie, a decrease in plasma conductivity).

Many specialists are working on the problem of improving the spectral composition of the radiation of high-pressure sodium lamps, and a number of foreign companies are already producing high-quality lamps with improved color parameters. So, in the nomenclature of such leading companies as General Electric, Osram, Philips there is a wide group of sodium lamps with improved color rendering properties.

Such lamps with a general color rendering index Ra = 50 — 70 have 25% lower light efficiency and half the service life compared to standard versions. It is worth noting that the main parameters of high-pressure sodium lamps are quite important for changes in the supply voltage. So, with a decrease in the supply voltage by 5-10%, the power, luminous flux, Ra lose from 5 to 30% of their nominal values, and when the voltage rises, the service life drops sharply.

Attempts to find an economical analogue of an incandescent lamp led to the creation of a new generation of sodium lamps. More recently, a family of low-power sodium lamps with improved color rendering has appeared. Philips introduced a series of 35-100 W SDW lamps with Ra = 80 and the emission chroma is close to that of incandescent lamps. The luminous efficiency of the lamp is 39 — 49 lm / W, and the lamp system — ballast 32 — 41 lm / W.Such a lamp can be successfully used to create decorative light accents in public places.

° The OSRAM COLORSTAR DSX lamp range, together with the POWERTRONIC PT DSX electronic control unit, is a completely new lighting system that allows, using the same lamp, to change the color temperature. Changing the color temperature from 2600 to 3000 K and back is done using an electronic ballast with a special switch. This allows you to create a light interior for the exhibits displayed in showcases corresponding to the time of day or season. The lamps of this series are environmentally friendly, as they do not contain mercury. The cost of a lighting installation made of such kits is 5-6 times higher than that of incandescent halogen lamps.

A modified version of the COLORSTAR DSX system, COLORSTAR DSX2, has been developed for outdoor lighting. Together with a special ballast, the luminous flux of the system can be reduced to 50% of the nominal value. This series of lamps also does not contain mercury.

Low power high pressure sodium lamps

Among the currently produced high-pressure sodium lamps, the largest share falls on lamps with a power of 250 and 400 watts. At these powers, the efficiency of the lamps is considered maximum. Recently, however, there has been a significant increase in interest in low-wattage sodium lamps due to the desire to save electricity by replacing incandescent lamps with low-wattage discharge lamps in indoor lighting.

The minimum power of high-pressure sodium lamps achieved by foreign companies is 30 — 35 W.The gas discharge lamp plant in Poltava mastered the production of low-power sodium lamps with a power of 70, 100 and 150 W.

Difficulties in creating low-power sodium lamps are associated with the transition to small currents and diameters of discharge pipes, as well as with an increase in the relative length of the electrode areas compared to the distance between the electrodes, which leads to a very high sensitivity of the lamp to the mode of supply, to deviations in the design dimensions of the exhaust pipe and pipes and the quality of the materials. Therefore, in the production of low-power sodium lamps, the requirements for compliance with the tolerances for the geometric dimensions of the exhaust pipe assemblies, for the purity of the materials and the accuracy of dosing of the filler elements are increased. Basic technologies already exist to master the mass production of these economical, long-lasting light sources.

OSRAM also offers a series of low-power lamps that do not require an igniter (the burners contain a Penning compound). However, their light efficiency is 14-15% lower than that of standard lamps.

One of the advantages of lamps that do not require a pulse igniter is the ability to install them in mercury lamps (under other necessary conditions). For example, the NAV E 110 lamp with a luminous flux of 8000 lm is quite interchangeable with a mercury lamp of the DRL -125> type with a nominal luminous flux of 6000 — 6500 lm. Similar internal developments have long been used in our country. Currently, LISMA OJSC, for example, produces DNaT 210 and DNaT 360 lamps, intended as direct replacements for DRL 250 and DRL 400, respectively.

Mercury-free NLVD

In recent years, notable efforts have been made in the field of environmental protection in many countries. One area of these efforts is to reduce or avoid the occurrence of toxic compounds of heavy metals (eg, mercury) in industrial finished products. Thus, mercury-containing medical thermometers are gradually being replaced by mercury-free ones.

The same trend is widespread in the field of light source manufacturing technologies. The mercury content in a 40-watt fluorescent lamp has dropped from 30 mg to 3 mg. In the case of high-pressure sodium lamps, this process does not progress so quickly, also because mercury greatly increases the efficiency of these light sources, which are recognized as the most economical today.

Existing and developing mercury-free lamps appear to have a bright future. The already mentioned series of Osram COLORSTAR DSX lamps does not contain mercury, which is a great achievement of the company. These lamps, along with special electronic ballasts, are special purpose systems where efficiency and simplicity are not the highest priority.

Sylvania's line of mercury-free lamps has long been famous. The manufacturer pays special attention to the improved color rendering properties, comparing them with standard analogues of its own production.

Not so long ago, the development of engineers from Matsushita Electric (Japan) was published, which is a mercury-free NLVD with high color rendering that does not require a special pulse ballast.

At the end of the service life of a traditional lamp, the color of the radiation takes on a pinkish hue, due to a change in the ratio of sodium to mercury in the amalgam.This shade does not create a particularly pleasant impression, in contrast to the yellowish color of the test lamp under the same conditions. As the color temperature increases, Ra first increases to a maximum level (at T = 2500 K), then falls.

To reduce the deviation, the developers have changed the xenon pressure and the internal diameter of the burner. It was concluded that the deviation from the blackbody line decreases with increasing xenon pressure, but the ignition voltage increases. At a pressure of 40 kPa, the ignition voltage is about 2000 V, even taking into account the presence of a circuit to facilitate it. When the inner diameter changes from 6 to 6.8 mm, the deviation from the black line of the body decreases, but the luminous efficiency decreases, which is unacceptable for the task at hand.

A mercury-free high-Ra sodium lamp has almost the same characteristics as its mercury-containing counterpart. A mercury-free lamp has 1.3 times the life.

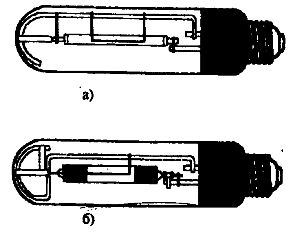

150 W high-pressure lighting lamps with a high color rendering index: a — mercury-free, b — the usual version.

High pressure sodium lamps with two burners

The recent appearance of serial samples of high-pressure sodium lamps with parallel-connected burners from a number of leading manufacturers suggests that this direction is promising, since such a solution not only contributes to a significant increase in lamp life, but also removes the complexity of immediate re- ignition, expands the potential for combining burners with different power, spectral composition, etc.

Despite the stated solid service life, the question of durability of these lamps should be approached with caution.The service life of such a lamp is only really doubled if the burner lamps light continuously throughout the life of the lamp. Otherwise, at the end of the resource, the working burner often begins to partially bypass the second (this phenomenon is sometimes called electrical «leakage»; in this case, the rarefied gas in the outer bulb is broken by the voltage of the ignition pulses), and therefore difficulties may arise with its ignition.

High pressure sodium lamps with high voltage igniter

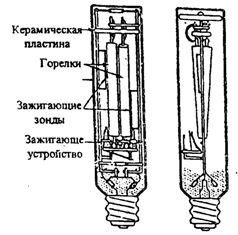

Japanese engineers (Toshiba Lighting & Technology offer an optimal, from their point of view, solution to eliminate the above-mentioned phenomena in a lamp with two burners. The design of the lamp contains two ignition probes that ensure the ignition of a certain burner when it is positive or negative pulses are supplied . Ballasts for such lamps contain two windings The circuit is quite simple and inexpensive. Due to this design, the lamps of the burner light up alternately. The alternating ignition of the burners ensures less «aging» of the burners and significantly increases the overall work Engineers from the same company offer a lamp with a built-in igniter that does not require a complex control scheme.

Some trends in the development of high-pressure sodium lamps

In what directions are designers and researchers looking for effective solutions for high-pressure sodium lamps? To answer this question, we must first address the obvious disadvantages of these lamps related to visual comfort, simplicity and the necessary electrical safety of the construction.Among them, several main ones can be distinguished: poor color rendering properties, increased pulsation of the light flux, high ignition voltage and even more — re-ignition.

Judging by the characteristics of lamps with high color rendering, the developers managed to get close to the optimal for this group of light sources. The fight against radiation ripple, which reaches 70-80% in high-pressure sodium lamps, is usually carried out using common methods, such as switching lamps in different phases of the network (in installations with many lamps) and supplying high- frequency current. The use of special electronic ballasts practically eliminates this problem.

The pulse ignition devices (IZU) currently used with most NLVD - PRA kits complicate the operation of the lamps and increase the cost of the lamp - PRA kit. IZU ignition pulses negatively affect the ballast and lamp, there are premature failures of these devices. Therefore, developers are looking for ways to reduce the ignition voltage, which allows you to abandon the IZU.

The problem of providing immediate re-ignition is usually solved in two ways. It is possible to use igniters that emit pulses of increased amplitude, or to use the mentioned two-burner lamp, which does not require such devices.

The service life of sodium lamps is considered the longest among high intensity light sources. However, in this area designers want to achieve the best.It is known that the service life and the drop in luminous flux during operation depend on the rate at which the sodium leaves the burner. The leakage of sodium from the discharge leads to the enrichment of the composition of the amalgam with mercury and an increase in the voltage of the lamp to (150 — 160 V) until it goes out. Much research, development and patents have been devoted to this problem. Among the most successful solutions, it is worth noting the amalgam dispenser from GE, used in serial lamps. The design of the dispenser ensures a strictly limited flow of sodium amalgam in the discharge tube throughout the life of the lamp. As a result, the service life is increased, the darkening of the ends of the tube is reduced, and the luminous flux remains almost constant (up to 90% of the original value) .

Of course, the research and improvement of high-pressure sodium lamps is not over yet, and therefore we should expect new, possibly exclusive solutions in a large family of these promising light sources.

Used materials from the book "Energy saving in lighting". Ed. Prof. Y. B. Eisenberg.