The choice of switching and protective equipment in lighting networks

All lighting networks must be protected against short-circuit currents and, in some cases, against overloads.

All lighting networks must be protected against short-circuit currents and, in some cases, against overloads.

Overload protection must have:

- indoor lighting networks made with exposed conductors with a combustible outer sheath or insulation;

- lighting networks in residential and public buildings, in commercial premises, offices and facilities of industrial enterprises, including networks for household and portable electrical receivers (irons, kettles, tiles, room refrigerators, vacuum cleaners, washing and sewing machines, etc.), when all types of wires, cables and wiring methods;

- networks in explosive and fire-hazardous areas with all types of wires, cables and wiring methods.

Protection of lighting networks is carried out by protective devices — fuses and circuit breakers (automatic devices), which turn off the protected electrical network under abnormal conditions. For the protection of lighting networks, the most common are automatic devices.One of the advantages of circuit breakers over fuses is that they can be used not only for protection, but also for disconnection.

Fuses or circuit breakers must be installed in all places in the network where the cross-section of the wire decreases towards the places of energy consumption. However, the installation of protective devices is not required if the previous device protects wires with a smaller cross-section. Naturally, security devices must be installed at the beginning of all network heads.

When making branches to the shields from the power network, protective devices should not be installed with a branch length of up to 1 m. It is allowed to make branches to the shields with the installation of protective devices at a distance of up to 30 m from the branch, if the wires when laying in steel pipes will not have a throughput of less than 10%, and in open laying — not less than 50% of the throughput of the supply line. Such a deviation from the general rule, in particular, has in mind the branches of the supply lines laid in the workshop at high altitude, where the maintenance of protective devices is very difficult.

Regardless of the general requirements, in order to increase the reliability and ease of operation of lighting installations, it is recommended to install protective devices:

1. in places where the supply network branches in more than three directions;

2. at the beginning of the feeder risers serving three or more shields;

3. at the entrances of the building;

4. at the beginning of the branches from the main line of the block system, the transformer — the main one;

5. in outdoor lighting installations with a branch to each lighting fixture;

6.in local lighting installations on the underside of step-down transformers.

Fuses compared to vending machines, due to their simplicity and low cost, they are still widely used. The fuse consists of a housing of one construction or another and a closed fuse link. A fusible link is made of a fusible wire that heats up strongly and then melts when a current in excess of the rated current is passed through it. The fuse housing allows the installation of a series of fuses in it for a certain range of currents. In this way, it is possible to select the appropriate fuse connection for a particular case, using one or more types of fuses.

The following fuses are most often used in lighting networks:

— plug type H;

— pipe types PR.

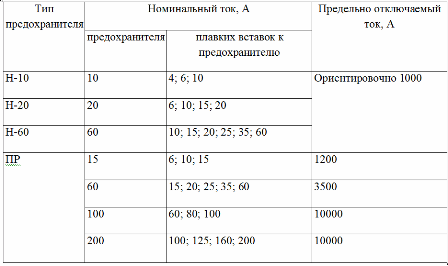

The types of fuses used and the values of the rated currents of the fuses for them are given in a table. 1.

H-10 plug fuses have a small E14 thread and are only used for auxiliary circuits (eg signal circuits).

Low mechanical strength does not allow their proper use lighting networks… H-20 fuses have a normal E27 thread and are mainly used for group lighting networks.

H-20 fuses are produced with a square base of dimensions 55 x 55 mm, height 60 mm and a rectangular base - 90 x 50 mm, height 55 mm. Wires are connected to the first one from the back, and the second - rectangular fuses, have two designs: for connecting wires from the front and for connecting from the back side to the wire pins.

Fuses of the H-60 type, with a large EZZ thread, are used only in power networks, and then only in those facilities where there are no permanent service personnel. In all other cases, the installation of PR-type pipe fuses should be recommended in the supply network. Such a limitation for H-type fuses is due to the relatively small values of the maximum permitted breaking currents.

Table 1. Rated currents of N and PR fuses and fuses to them

PR-type fuses, unlike H-type fuses, have open current-carrying parts, which is why only special personnel are allowed to service them. The advantages of PR fuses include a large maximum breaking current. Their main field of application is the protection of individual sections of the power grid.

The more the current that blows the fuse exceeds the rated current of the fuse, the shorter the time it will take to blow it. However, fuse fuses do not blow immediately when more than the rated current flows through them. Almost instantaneous (several seconds) fuse burning is guaranteed only at a current exceeding 2.5 times the rated current.

During the tests, the fuses withstand one and a half current for at least 1 hour, and a current exceeding the nominal by 20 - 30% - for an indefinite time. Under operating conditions, the fuse material oxidizes and ages and often burns out at close to rated current. Therefore, to avoid false tripping, the fuses should not be loaded with a current higher than the rated current.

Current electrical regulations require that the rated current of the fuse is not less than the operating current of the load, i.e.

Recently, there has been a trend to replace fuses with automatic controllers. Advances in technology have made it possible to design machines with good electrical data (large maximum interrupting currents — up to 10,000 A, fast shutdown in case of short circuit) and with structural dimensions that are extremely convenient for installation on shields.

The design features of the machines are the possibility to combine the functions of the fuse and the switch in the machine, the guaranteed safety of their maintenance and the convenience of assembly in small-sized reliable shields. Machines are manufactured with separators containing only thermal or thermal and electromagnetic relays.

Thermal relay operates in the overload zone and shuts down the machine after time intervals that are inversely proportional to the magnitude of the overload, and the electromagnetic relay shuts down the machine immediately in the event of a short circuit.

The conditions for the protection of wires and cables from automatic installation machines are close to the conditions for the protection of fuses. Therefore, the tuning current of the tuning machine must be not less than the operating current of the load, i.e.

In calculations using these formulas, the rated fuse currents of fuses or currents from the settings of automatic machines should not be selected that are unnecessarily large.As a rule, the rated fuse current of the fuse or the setting current of the setting machine should be taken equal to or closest to the large values of the expressions on the right-hand side of the ratios, respectively.

The selection of automatic machine settings without delay is made directly according to the tables, the proposed PUE.

The cross-sections of the drives and cables must be such that, for a given operating current and the selected fuse, the temperature of the working wires does not reach values where the mechanical strength of the wire is impaired, a fire hazard occurs or the insulation of wires and cables is broken. Therefore, in all cases, the long-term permissible conductor current Iadm must be not less than the operating current determined by the design load, i.e.

In addition, the cross-sections of wires and cables must correspond to the ratios

where β is a coefficient that determines the margin in the cross-section of wires for rooms where electrical wiring can introduce elements with an increased fire hazard.

When protected by fuses in industrial premises of industrial enterprises β = 1, in residential buildings, domestic and public premises, flammable warehouses and service premises of industrial enterprises β = 1.25. In case of protection by automatic devices in all cases β = 1.