Mitsubishi Alpha XL Smart Relays — advanced automation with Mitsubishi

The line of alpha controllers from Mitsubishi Electric fills the gap between independent elements (timer, relay, etc.) and miniature controllers, which in some cases are not suitable. The new controller has good functionality, reliability and excellent customization flexibility.

The line of alpha controllers from Mitsubishi Electric fills the gap between independent elements (timer, relay, etc.) and miniature controllers, which in some cases are not suitable. The new controller has good functionality, reliability and excellent customization flexibility.

It can be used both in existing automatic control systems and in those that are just being created. Mitsubishi Alpha XL intelligent relays can process up to two hundred special blocks in one program. In addition, any independent function (counter, timer, etc.) the device can perform any number of times in each program.

Mitsubishi Alpha XL Smart Relay Application

Devices from the Alpha line can be easily applied wherever control is required, at home, in the office or in industrial buildings. The controller performs on/off operations. in outgoing circuits, in order to control electrical equipment, in accordance with the established program.

Let's look specifically in which areas these controllers can be used (programmable intelligent relays) for automation:

• Automation of lighting systems, cooling, heating or irrigation systems;

• Opening and closing robots;

• Distribution systems for animal feed, industrial livestock and home production.

• Control over the functioning of greenhouses and cattle yards;

• Simple security systems;

But there are areas where such controllers cannot be used, these include:

• Fields requiring high reliability, this includes a variety of transportation, medical equipment, combustion management, as well as nuclear power;

• Areas of use that can critically affect the safety of a person's life.

Features of the Mitsubishi Alpha XL intelligent relay device

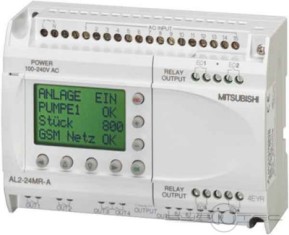

The device has a liquid crystal display that can display system performance information as well as various errors and error messages. Screen features and capabilities:

• The maximum number of characters is 12 on four lines;

• The following data can be displayed on the screen: message, current or set value for the counter and timer, different values, etc.

Quick and easy programming of the device using a personal computer. Special software has been developed for the Windows operating system that allows you to develop and write programs. Programming can be done using a visual method, during which lines are used that connect blocks in the work window. In addition, the device can be programmed using the buttons located on the device itself.

The device can transmit messages that are displayed on the screen by e-mail thanks to the modem installed in it. Therefore, the user will be able to monitor the progress of the programmed tasks even from a distance.

The controller can work in communication with a computer using a specially developed protocol. This allows you to monitor the execution of programs through the computer, as well as make any changes to the function blocks.

Improved clock. The calendar and timers are equipped with a variety of functions, thanks to which you can set any switching time, which gives huge opportunities for management according to time constraints.

A high-speed counter is installed, as well as two analog outputs.

It has a built-in storage device that avoids the need for additional power supplies to ensure the storage of information.

The device supports six languages: English, French, German, Spanish, Swedish and Italian. You can select the user's desired language using the top menu.

Features of assembly and disassembly

Alpha series programmers have a safe design, so the user can install them anywhere. But still, some nuances should be taken into account.

Do not install the devices in extremely dusty places, especially if the dust conducts electricity, as well as in places where there are flammable gases, where excessively high humidity is observed. Installation is not allowed where the equipment may be exposed to rain, in very "hot" places, as well as in places with vibrations, as the device may suffer various mechanical damage and be damaged.The controller must not be immersed in water or spilled on it.

During installation, you need to make sure that various construction waste does not fall into the mechanism.

It is necessary to install the device as far as possible from high voltage wiring and other power equipment.

According to the instruction manual, the device must be installed in a control box or in a control stand. In case of mounting with screws, size M4 should be used. Connecting elements must be covered with covers to exclude the possibility of electric shock. It is imperative to leave ventilation gaps between the power supply and the racks. The manufacturer forbids disassembling the device yourself.

Installing the main unit. The controller can be installed using locks that are attached to a special rail. To disconnect it, you need to pull the latches on the side of the rail and then simply remove it by moving it upwards. So, to install the device, you need to connect the upper part of the groove, which is on the body, with the rail, which is intended for installation and has a suitable standard. Then you just need to slide the controller onto the bus. To disassemble, you need to pull down the hook that holds the device on the rail and then simply remove it.

The device from the "Alfa" line is designed in such a way as to guarantee maximum user safety during the installation of electrically conductive connections.