Reliability of electrical products and devices

Among the properties that determine the quality of an electrical product, a special place is occupied by reliability — the ability of the product to perform its functions, keeping the values of the quality indicators unchanged over time or within predetermined limits.

Among the properties that determine the quality of an electrical product, a special place is occupied by reliability — the ability of the product to perform its functions, keeping the values of the quality indicators unchanged over time or within predetermined limits.

Electrical product — a product intended for the production or conversion, transmission, distribution or consumption of electrical energy (GOST 18311-80).

Any electrical product or device can be in one of the following states:

-

upright

-

defective,

-

working

-

non-working

-

limiting.

A product that is in good working order is also working, but a working product is not necessarily a good product. For example, damage to the generator housing (dents, scratches, defects in the painted surface, etc.) renders the generator inoperable, but at the same time it remains functional.

As a rule, the working state of the product is determined by the list of parameters specified in the documentation and the permissible limits for their change. Loss of productivity is called rejection.

The reasons for failure can be both exceeding the permissible level of external influences and product defects... Remember that not all defects lead to failure. The failure of a product is assessed by the appearance of noise, the appearance of the smell of burnt insulation and impregnating materials, overheating, a change in the readings of control devices and instruments, etc.

By their nature, all defects and damages can be:

-

electric

-

mechanical

Electrical includes broken contacts, short circuits, open circuits, connection errors, etc.

Mechanical defects are malfunctions in the assembly of elements, transmission systems from servo motors to controls, actuators, moving parts of relays and contactors, etc.

Regarding the rules, methods and means of control, defects are divided into:

-

explicitly, for the detection of which the documentation provides rules, methods or controls,

-

hidden for which they are not intended.

For example, if the quality of a part is controlled only by measuring its geometric dimensions, then the deviation of these dimensions from the tolerance will be an obvious defect. At the same time, cracks and voids may exist inside the workpiece that cannot be detected when measuring the dimensions of the workpiece. With the control method adopted, these defects will be hidden. To detect hidden defects, other rules, methods and means of control are used, which are not provided for in the documentation for this product, in particular, voids and cracks can be detected by X-ray examination.

Malfunctions can occur for various reasons, but if they are not related to the malfunction of other elements, then they are called independent.Failure resulting from another failure is considered dependent (for example, failure of a transistor after disconnection of its base to the circuit).

Usually, reliability is associated with the absence of failures, that is, with its reliability.

In general, reliability includes, in addition to reliability, such properties as durability, maintenance, preservation... It is usually called a quantitative assessment of the properties included in reliability reliability indicators... The main difference between reliability indicators and other indicators is that, regardless of the dimension, they all are non-random characteristics of random variables.

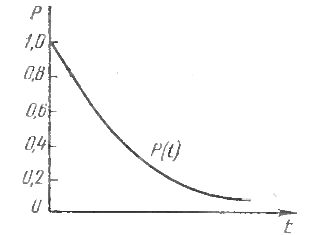

Let's explain the content of such a property as reliability, expressed by the indicator «probability of failure-free operation». Suppose that at time t = 0, n similar products are simultaneously involved in the work. After a time interval Δt = t, there will be m products to serve. Then the probability of failure-free operation at time t — P (t) can be defined as the ratio of m — the number of products that work at time t to the total number of products n, i.e.

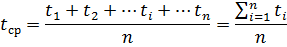

In the simultaneous operation of n products, such a time point t1 occurs when the first product fails. At time t2, the second product fails. With long enough operation, there will come a point in time tn when the last of the n products will fail. Since tn> … t2> t1, it is impossible to uniquely determine the operation time of another product from the operation time of one product. Therefore, the duration of work is determined as an average value

From the graph (Fig. 1), it can be seen that the probability of failure-free operation changes over time.At the initial moment of time, the probability of failure-free operation P (t) = 1, and during the average time of failure-free operation tcp, the value of P (t) decreases from 1 to 0.37.

During 5 tcp, almost all n products will fail and P(t) will be practically zero.

Figure 1. Dependence of the probability of failure-free operation of the product on time

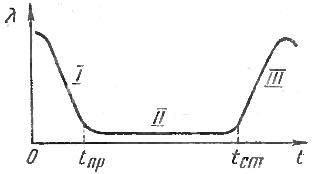

Rice. 2. Dependence of the failure rate of products on time

Product damage depends on the time of its operation. The probability of product failure in each unit of time, if the failure has not yet occurred, is characterized by the failure rate and denoted by λ (t). This indicator is called the lambda characteristic. Three main periods of λ change over time can be distinguished (Fig. 2): I-the run-out period lasting from 0 to tpr, II-the period of normal operation from tpr to tst, III — aging period from tst to ∞ …

In period I, the degree of damage increases, which is explained by the presence in the product of elements with hidden defects, violations of the technological processes of product production, etc. Period II is distinguished by the relative constancy of λ (t), which is explained by the absence of aging of the elements. After the end of period II, λ (t) increases sharply due to an increase in the number of elements that have failed due to aging and wear. Operation of the product during period III becomes economically impractical due to the sharp increase in repair costs. Therefore, the time period before tst determines the average service life of the product before disposal.

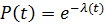

The failure rate λ (t) and the probability of failure-free operation P (t) of the product are related to each other by the ratio

This expression is called the exponential law of reliability.

The value of the reliability indicators recorded in the technical documentation of the product must be confirmed by special reliability tests, by modeling the processes of random failures of special devices, including with the help of a computer or by calculation. It should be noted that the calculation method is used in the design of a product almost always, regardless of whether other methods will be used to confirm reliability.

When calculating the reliability of a product, either tabular indicators of the reliability of the elements included in the product are used, or data obtained by any of the above methods for products similar to the designed ones.

Of the known reliability calculation methods, the simplest is the coefficient method, for which the damage rate λ (t) is constant over time. If necessary, the influence of operating modes and operating conditions on the reliability of the product is taken into account by the correction factors k1, k2,... kn

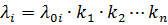

The degree of failure of a given element in real operating conditions λi is calculated by the formula

where λоi is the table value of the degree of damage of an element operating under normal conditions, k1 ... kn are correction coefficients depending on various influencing factors.

The values of the coefficient k1 depending on the influence of mechanical factors under different operating conditions are given below:

Operating Conditions Correction Factor Laboratory 1.0 Impatient 1.07 Ship 1.37 Automotive 1.46 Railroad 1.54 Aircraft 1.65

The coefficient k2, depending on the climatic factors of the environment, can have the following values:

Temperature Humidity Correction factor +30.0±10.0 65±5 1.0 +22.5±2.5 94±4 2.0 +35.0±5.0 94±4 2.5

Correction factors for other factors can be found in reliability manuals.

Special reliability tests are the main method of confirming the reliability indicators specified in the technical documentation. Such tests are carried out periodically within the period established by the technical specifications (TU) for the product, as well as in case of changes in the technology of production of the product or changes in components and materials, if these changes can affect the reliability of the product. The technical specifications contain a reliability test program containing, in addition to the sections provided by the ESKD standards, a test plan.

Test plan - rules that determine the number of products to be tested, the test procedure and the conditions for their termination.

The simplest test plan is when n similar products are tested simultaneously, the failed products are not replaced or repaired, the tests are stopped either after a predetermined test time has elapsed, or after each of the remaining operational products has operated for a predetermined time.

Product reliability indicators can also be determined as a result of collecting and processing information about the performance of the product during its operation.The forms of documents that are valid in different industries differ among themselves, but regardless of this, they must reflect the following information:

-

the total duration of the product,

-

Terms of Use,

-

the duration of product operation between failures,

-

number and characteristics of damages,

-

the duration of the repair to eliminate a specific damage,

-

type and quantity of spare parts used, etc.

In order to obtain reliable indicators of product reliability based on operational data, information on failures and defects must be continuous over time.