UPD-M hydrocarbon dielectric paste

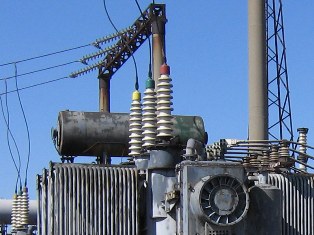

Hydrocarbon dielectric paste UPD-M is intended as an auxiliary material for covering high-voltage insulators of electrical substations located in areas with a polluted atmosphere.

Hydrocarbon dielectric paste UPD-M is intended as an auxiliary material for covering high-voltage insulators of electrical substations located in areas with a polluted atmosphere.

UPD-M paste can also be used for:

-

application of anti-corrosion water-repellent coatings on metal products, to protect contacts, live parts, etc. from atmospheric influences,

-

preservation of parts, devices and mechanisms before long-term storage or transportation by sea to countries of tropical and subtropical climate zones,

-

for sealing low-current, automotive low-voltage and high-voltage equipment in order to increase its reliability by isolating it from moisture, as well as to reduce the leakage currents of electronic circuits, batteries, etc.,

-

it is possible to use the UPD-M paste as a lubricant for friction units operating in a humid dusty atmosphere (gears of open gearboxes).

Hydrocarbon dielectric paste UPD-M is obtained by thickening a mixture of petroleum oils with solid hydrocarbons and synthetic polymers.

The paste is inert to most chemical reagents. It can be used at air temperatures from minus 40 ° C to plus 55 ° C.

According to its main physical characteristics, the hydrophobic coating based on UPD-M paste belongs to the class of viscous (amorphous); but to some extent possesses the properties of wax film coatings, i.e. in the presence of good adhesion to the surface of the products (insulators, electrical contacts, etc.), a wax layer with a high surface tension is formed on the outer surface of the hydrophobic coating, preventing the adhesion of dust particles.

Due to the hydrophobic effect of the protective layer, atmospheric precipitation does not form a surface water film, and dust on the surface of the insulator is captured by drops of running water and washed away. Nevertheless, the paste has the property of "washing out" the impurities, but this property is less pronounced than that of the silicon silica pastes.

As a result of testing UPD-M paste, it was found that the wet discharge voltage of high-voltage insulators soaked in salted water (1% NaCl) in the case of using UPD-M paste is 2 times higher than without the pasta. The UPD-M paste showed itself well in the conditions of annual operational tests at the Novo-Sverdlovsk TPP and traction substations of the Bereznikovska power supply distance of JSC "Russian Railways". During the tests, no emergency situations were registered.

The UPD-M paste is a full replacement for the UPD paste (discontinued in January 2013) and has a number of advantages over the latter:

-

improved thermophysical characteristics (increased drop and creep temperatures: up to 105 ° C and up to 80 ° C, respectively),

-

increased colloidal stability (the ability to retain oil in the paste structure).

In OAO "SVERDLOVENERGO" UPD paste was used from 1998 to 2012 to cover the external porcelain insulation of electrical equipment of electrical installations up to 220 kV inclusive, operating in atmospheric pollution conditions. In addition, it has been used to seal the reinforcing joints of valve restrictors, surge arresters and support rod insulators to increase the reliability of their operation. In recent years, there have been no cases of overlapping insulation of electrical equipment covered with UPD paste.

Based on the results of operational tests of UPD (UPD-M) paste applied to the insulation of working electrical installations of the distribution and switchgear, as well as the results of laboratory tests of the paste and control insulators installed in areas with salt retention, can to claim that the hydrocarbon paste UPD-M is suitable for use as a protective coating on the insulation of electrical equipment of distribution and distribution devices in areas with a polluted atmosphere, in all climatic zones.

Properties of UPD-M paste and conditions for its application on high voltage insulators

For UPD-M paste, the drop point is in the range 95-105 ° C, therefore, UPD-M paste can be used in any climatic zone, at ambient temperatures from -40 to + 55 ° C.

UPD-M hydrocarbon paste is a combustible substance with a flash point (approximately) 211 °C and an ignition temperature (approximately) 234 °C.

UPD-M paste is obtained by thickening a mixture of petroleum oils with solid hydrocarbons and synthetic polymers and under normal conditions does not release harmful substances into the air of the working area, but when applying the product to high voltage insulators, it is recommended to use rubber gloves.

If the UPD-M paste gets on the skin of the hands, it is washed off with hot water and soap.

The main differences between UPD-M paste and silicon silicon pastes:

-

UPD-M paste is inert to most chemicals, including alkaline,

-

thermoreversible,

-

resistant to partial dilutions,

-

combines the properties of viscous (amorphous) and film coatings,

- in cooling tower salt extraction conditions, an increased service life of UPD paste (UPD-M) was found.

The paste is exploited in the Novo-Sverdlovsk TPP, operating on natural gas; under these conditions, within 3 years of operation, the KPD silicon silica paste was completely cemented, which caused great difficulty in removing the paste.

The application of paste on insulators should be carried out with the equipment turned off in clear weather at an air temperature of at least 10 ° C in August - the first half of September, in order to achieve a good insulating condition during the period of unfavorable humidification (October-April) , but in urgent cases deviations from this were allowed regulations.

Insulators must be cleaned before applying the paste, the paste is applied manually using rubber gloves.

It is recommended that the paste replacement time be determined in practice at each specific facility.

To facilitate the application of the paste on the insulators, the package with UPD-M paste can be preheated in an oven at 35-40 ° C for 3-5 hours; you can also heat the paste by placing the pack near a hot radiator to heat until a spreadable consistency is achieved.

If a drop of oil is noticed on the surface of the product when opening the package with the paste, the oil should be removed with a piece of clean colorless foam and only then use the product.

The hardened layer of the used UPD-M paste, which cannot be removed with a rag, is removed with white spirit.

Additional areas of application of the dielectric hydrophobic paste UPD-M: application of anti-corrosion water-repellent coatings on metal products (in particular: anchor bolts for foundations), as well as for weather protection of contacts, live parts, etc. , preservation of parts, devices and mechanisms before long-term storage or transportation by water (sea) to countries of tropical and subtropical climatic zones and factory processing of insulators before storage - to increase their storage and service life, sealing of low-current, automotive equipment for low and high voltage in order to increase its reliability by isolating it from moisture, as well as to reduce the leakage currents of electronic circuits, batteries, etc., treating any contact connections, in particular the contact connections of the battery cells, as a lubricant for friction units operating in a humid dusty atmosphere (gears on gears with ktorov open reducers).