Smart appetizers

In motor control design, the choice of contactors or circuit breakers is by no means a primary concern. The capabilities of these devices, as well as their reliability and quality in general, are little taken into account. In the meantime, the compliance of these devices with the requirements for proper compatibility with other parts of the automated system must be assessed.

In motor control design, the choice of contactors or circuit breakers is by no means a primary concern. The capabilities of these devices, as well as their reliability and quality in general, are little taken into account. In the meantime, the compliance of these devices with the requirements for proper compatibility with other parts of the automated system must be assessed.

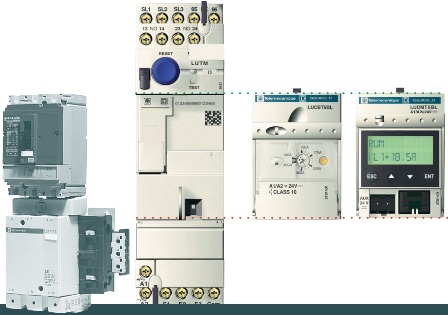

The first intelligent starter «TeSys U» was put on the market by the French company Schneider Electric. In addition to functions such as starting and controlling electric motors up to 315 kW, the new type of starter adds other additional functions.

The starter consists of two main elements - the control unit and the power supply unit. Thus, the starter can perform the tripping, overload and short-circuit protection functions as well as the load switching functions.

Innovation is the implementation of all these capabilities in one compact device that can be supplemented without increasing the dimensions, with modules that expand the standard capabilities of the starter to integrate into a modern industrial automation system.

Power supplies can be of two different types, depending on the power of the electric motor, for operating currents up to 32 amperes and up to 12 amperes.

There are three management options: standard, advanced and multi-functional. The choice of control unit and powertrain options is determined by the engine output and the functions to be provided.

All devices have high-precision electronic protection and various diagnostic tools and visualization of operating parameters.

The standard control box is the most economical solution for the protection and control of three-phase motors. The extended control unit allows control of three-phase and single-phase loads while providing Class 10 or Class 20 tripping plus the ability to add function or communication modules.

The multi-function block, in turn, makes it possible to set and monitor the main parameters of the electric motor, to change the protection parameters through a remote operator panel, computer or on-screen keyboard, since this block has its own screen where the set protection settings are displayed.

The screen shows the current parameters, such as the current and thermal status of the engine, as well as a list of operations and other events, running time, etc. It is also possible to implement special operating modes, such as no-load operation or delayed start operation.

To extend the starter's capabilities, in accordance with current tasks, a number of function modules are available, including an analog motor load indication module 4-20 mA, a thermal overload alarm module and alarm modules for signaling protection in the event of accident with subsequent return. This can be done automatically, manually or remotely.

Thanks to Modbus and AS-i communication modules, Fipio, Profibus DP, DeviceNet communication gateways and the operator panel of the Magelis XBT series, it is possible to easily integrate intelligent starters into various automated process control systems.

The reversing module added to the starter allows the motors to be operated in reverse mode. The reversing starter can be implemented by connecting a reversing module or ordered separately as a complete assembly. At the same time, the width of the starter is only 45 mm, which is half the size of any other solution.

The starter can be operated from either AC or DC, and the 24V coils have a low current draw, allowing the starters to be operated directly from the smart relay or controller outputs. This provides both easy integration with automation systems and a reduction in the number of power supplies. And the heat dissipation of starters is 4 times less compared to standard solutions.

Modular design, without wires, reduces installation time by 5 times compared to traditional solutions. The range of current settings has been expanded, so adaptation to different applications even after installation is not a problem. No need to reconnect the wires.

The uniform design of the products ensures the compatibility of the starters with Altistart U01 soft starters. PowerSuite software parameters for Altivar VFDs are also applicable here.

Smart starters remain operational even after an emergency situation, for example after a short circuit. Cleaning or replacement of contacts after this event is not required.

The starter-controller is designed to control loads with currents up to 800 amperes. It has the same dimensions and the same modular design as the lower current starters mentioned. But there are also a number of fundamental differences.

The main thing is that there is no switching function in the starter-controller, and the motor is controlled by turning on and off an additional device-an external contactor (non-reversible or reversible).

The starter-controller receives data from current transformers. There are also 10 inputs and 5 outputs for the exchange of data on the status of the starter (emergency events, readiness for operation, return functions, etc.) and a controlled contactor.

There are two options for implementing control blocks: multifunctional and advanced. They control electric motors up to 315 kW and perform the same functions as in starter control units for lower currents.

The capabilities of these starter controllers can also be extended with a Modbus communication module, a 4-20 mA motor load analog module or a thermal overload alarm module. The starter-controller is actually a multi-functional relay for protection and control of an electric motor.

The multifunctional representatives of the new switching electrical engineering, deservedly recognized in the world, will undoubtedly receive recognition in Russia as well.