Contactless control of electric drives

Electrical contacts are unreliable elements of an electrical circuit, as the electric arc occurring between them when opened gradually destroys and limits their service life.

Electrical contacts are unreliable elements of an electrical circuit, as the electric arc occurring between them when opened gradually destroys and limits their service life.

Environments saturated with water vapor, corrosive gases, shaking and vibration, which are not uncommon in manufacturing, also contribute to the premature failure of electromechanical devices. In addition, do not install conventional devices with sparking contacts in fire-hazardous rooms. Therefore, contact sensors, limit switches and limit switches, which must be located directly in the production premises, cannot be used.

Operational experience shows that the number of failures is particularly high in contact limit switches, time relays, intermediate relays. Therefore, in terms of production, contactless control schemes are promising, the implementation of which requires less additional costs, as well as completely contactless electric drive circuits.Thyristor switches are usually used in such circuits.

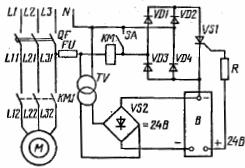

Figure 1 shows the control scheme of an electromagnetic starter using a thyristor switch.

Rice. 1. Squirrel rotor induction motor control circuit with contactless control circuit

Voltage non-contact limit switch (or another converter, regulator of temperature, humidity, illumination) instead of a relay is supplied to the control electrode of the thyristor VS1 and the circuit of the starter coil KM turns out to be closed.

If the voltage at the output of the converter disappears, for example, the plate is removed from the groove of the contactless limit switch B, the thyristor VS1 will close, and at the first passage of the pulsating half-wave of the voltage through zero, the current in the coil will disappear.

The switch SA is used for commissioning and manual control, the resistor R is used to limit the control current. The diagram also shows the breaker QF and the switch power supply unit B consisting of a transformer TV to rectifier VS2.

Such a scheme can be used, for example, to automate a reckless pumping station, if the control plate of the switch B is fixed on the moving part pressure sensor.

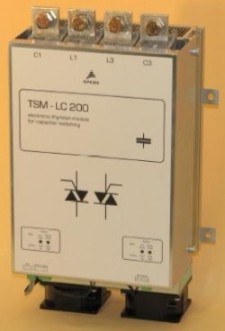

An example of a proximity switch is a complete HPC switch

An example of a proximity switch is a complete HPC switch

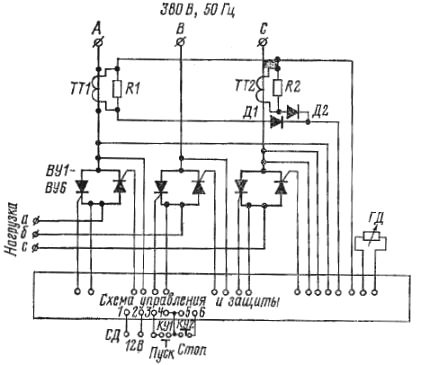

If instead of a conventional electromagnetic starter you use a thyristor starter, using the output voltage of the primary converters for control, you will get a completely contactless circuit.

Thyristor starter

See also: Thyristor contact management

Thyristor starters are designed for remote or local control and protection against overload and short-circuit currents of squirrel-cage induction motors. Compared to magnetic thyristor starters, they have the following advantages:

-

the absence of mechanical switching contacts, which excludes the formation of an electric arc during switching,

-

high switching capacity and long service life,

-

high system speed,

-

smooth start of the electric motor,

-

resistance to mechanical influences (impact, vibration, shaking, etc.).

Schematic diagram of a thyristor starter

More about thyristor starters: Thyristor control of an induction motor in a cage