Reducer for modular circuit breakers

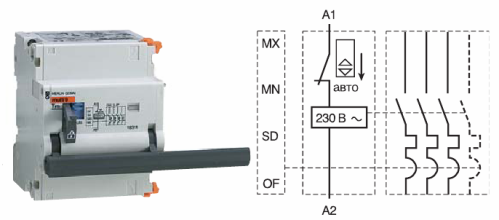

A modular circuit breaker gear motor is used to operate these devices by moving the electrical device control handle. Based on the name, it is obvious that this device structurally has two main elements - a gearbox that acts on the handle of the switch and an electric motor that drives the gearbox.

A modular circuit breaker gear motor is used to operate these devices by moving the electrical device control handle. Based on the name, it is obvious that this device structurally has two main elements - a gearbox that acts on the handle of the switch and an electric motor that drives the gearbox.

The geared motor, depending on the type, can operate circuit breakers with a number of poles from one to four. To control the circuit breaker using a motor with a reduction gear, it is enough to give a pulse that makes it possible to organize remote control of the machines manually, by giving commands to the service personnel, or automatically — when sending the control command to the reduction motor from the device for protection and automation.

Consider the main technical characteristics and functionality of gear motors for modular circuit breakers.

What functions do motor reducers provide on modular circuit breakers?

Above all, remote control of circuit breakers by pulse or fixed command.

The command to the geared motor can be given, manually, by pressing a button (pulse command) or by selecting one of the switch positions (fixed command).

The next function is — reclosing the breaker… The gear motor can trip the breaker in a predetermined mode. For example, an automatic reclosing feature can be implemented on an overhead power line that frequently experiences unstable emergency situations that self-disconnect in a short time.

For example, a strong wind caused the wires of the power line to collapse, resulting in a phase short circuit. When the wires have returned to their original position, the short circuit has cleared — in this case it is advisable to restore power to the line, which is done by the automatic circuit breaker reclosing function implemented by the gear motor.

Additional devices can be additionally installed on the motor-reducer, which expand its functionality. For example, a device may be installed which provides signaling and indication of the circuit breaker position, or a device which provides an immediate or predetermined time delay to close the circuit breaker when the mains voltage deviates from the specified value (range).

The gear motor for controlling automatic machines, as a rule, has a switch that allows you to turn off the remote (automatic) control mode of the electrical device. When selecting local mode, it is possible to control the circuit breaker by pressing the buttons located on the gear motor housing.

It is also possible to switch off the gear motor. In this case, the geared motor installed in tandem with the automatic machine does not interfere with the traditional manual control of electrical appliances.

In addition, the gear motor can be locked in the open position of the circuit breaker by installing a special lock. This feature is especially relevant in electrical installations when, when one of the lines is removed for repair, it is necessary to take measures to prevent wrong turning on the breaker through which voltage is supplied to the line brought out for repair. In this case, by blocking the motor with a reducer, the possibility of wrongly switching on the machine will be excluded.

In terms of powering the control circuits of the geared motor, there are several options in this case. Control circuits, as well as auxiliary elements providing the performance of additional functions, can be powered by both AC and DC mains.

Field of application of gearmotors for circuit breakers

Gearmotors for circuit breakers are widely used in automatic lighting, heating and motor control circuits for various purposes.

The ability to implement remote control makes it possible to implement the possibility of remote control of circuit breakers, for example from a central control.

Geared motors paired with circuit breakers can be considered as an alternative to many contactor based schemes (magnetic starters).